京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (5): 129-136.DOI: 10.19491/j.issn.1001-9278.2024.05.022

• Review • Previous Articles

CHEN Xiaoqing1, LIANG Jiahao1,2( ), XIE Wenyu2(

), XIE Wenyu2( ), SHAO Weiming3, WANG Ruzhen2, FU Wen3, CAI Yebin1

), SHAO Weiming3, WANG Ruzhen2, FU Wen3, CAI Yebin1

Received:2023-10-07

Online:2024-05-26

Published:2024-05-20

CLC Number:

CHEN Xiaoqing, LIANG Jiahao, XIE Wenyu, SHAO Weiming, WANG Ruzhen, FU Wen, CAI Yebin. Preparation of electrospun photothermal conversion nanofibers and their application in solar⁃driven interface evaporation[J]. China Plastics, 2024, 38(5): 129-136.

| 纤维膜类型 | 纤维膜 | 制备方法 | 制备工艺及关键参数 | 纤维形貌 | 蒸发速率/ kg·m-2·h-1 | 光热转换效率/% |

|---|---|---|---|---|---|---|

| 单层纤维膜 | PDA@CNT/PU复合膜[ | 静电纺丝+原位聚合 | U=15 kV、Q=1.2 mL/h静电纺制得PU/CNT纤维后置于pH=8.5的PDA溶液超声水浴6 h。 | 分层纳米结构,微纳级孔互相粘连 | 1.44 | 90.1 |

| PAN@PPy复合膜[ | 静电纺丝+原位聚合 | U=22 kV、D=15 cm、Q=0.5 mL/h静电纺制得PPy纤维后,60 ℃干燥12 h使PAN聚合。 | 孔隙丰富、纤维表面粗糙 | 1.63 | 83.5 | |

| PVA/GO复合膜[ | 静电纺丝法+热处理 | U=15 kV、D=15 cm、Q=0.7 mL/h静电纺制得PVA/GO纤维,180 ℃热处理30 min。 | 介孔丰富、密度低 | 1.42 | 94.2 | |

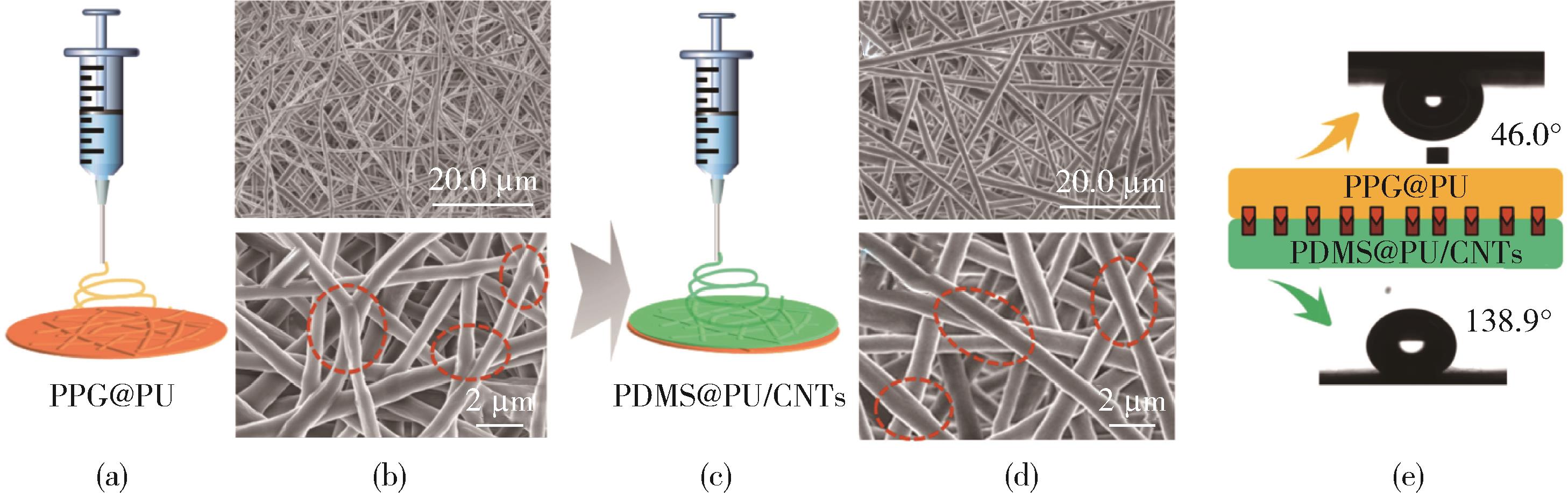

| Janus结构纤维膜 | PPG@PU/PDMS@PU⁃CNTs复合膜[ | 两步静电纺丝 | U=12 kV、D=15 cm、Q=0.5 mL/h静电纺制备PPG@PU纤维膜,U=10 kV、D=15 cm、Q=1.8 mL/h静电纺制备PDMS@PU⁃CNTs。 | 三维微孔结构,纤维膜界面紧密连接 | 1.34 | — |

| PMMA/PAN/CB复合膜[ | 静电纺丝+喷涂沉积 | 在以U=14 kV、D=15 cm、Q=1.6 mL/h静电纺制得的PAN纤维膜上纺PMMA纤维膜(U=15 kV、D=15 cm、Q=3 mL/h),CB悬浮液喷涂至膜表面。 | 高度开放的三维微孔纳米纤维结构 | 1.30 | 72.0 | |

| CA/PAN/CNT复合膜[ | 静电纺丝+沉积 | 在以U=25 kV、D=15 cm、Q=1.0 mL/h静电纺制得的CA纤维膜上纺PAN纤维膜(U=18 kV、D=10 cm、Q=3 mL/h),CNT喷涂沉积在PAN膜表面。 | 无序填充的无纺布结构,碳纳米管附着在纤维表面 | 1.94 | 92.7 | |

| TPC/CB复合膜[ | 静电纺丝+涂覆 | U=14 kV、D=28 cm、Q=0.5 mL/h静电纺制得TPC纤维膜,通过真空过滤和干燥涂覆上CB。 | 多孔胞腔结构,CB附着在纤维表面 | 1.80 | 97.2 | |

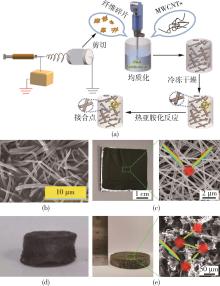

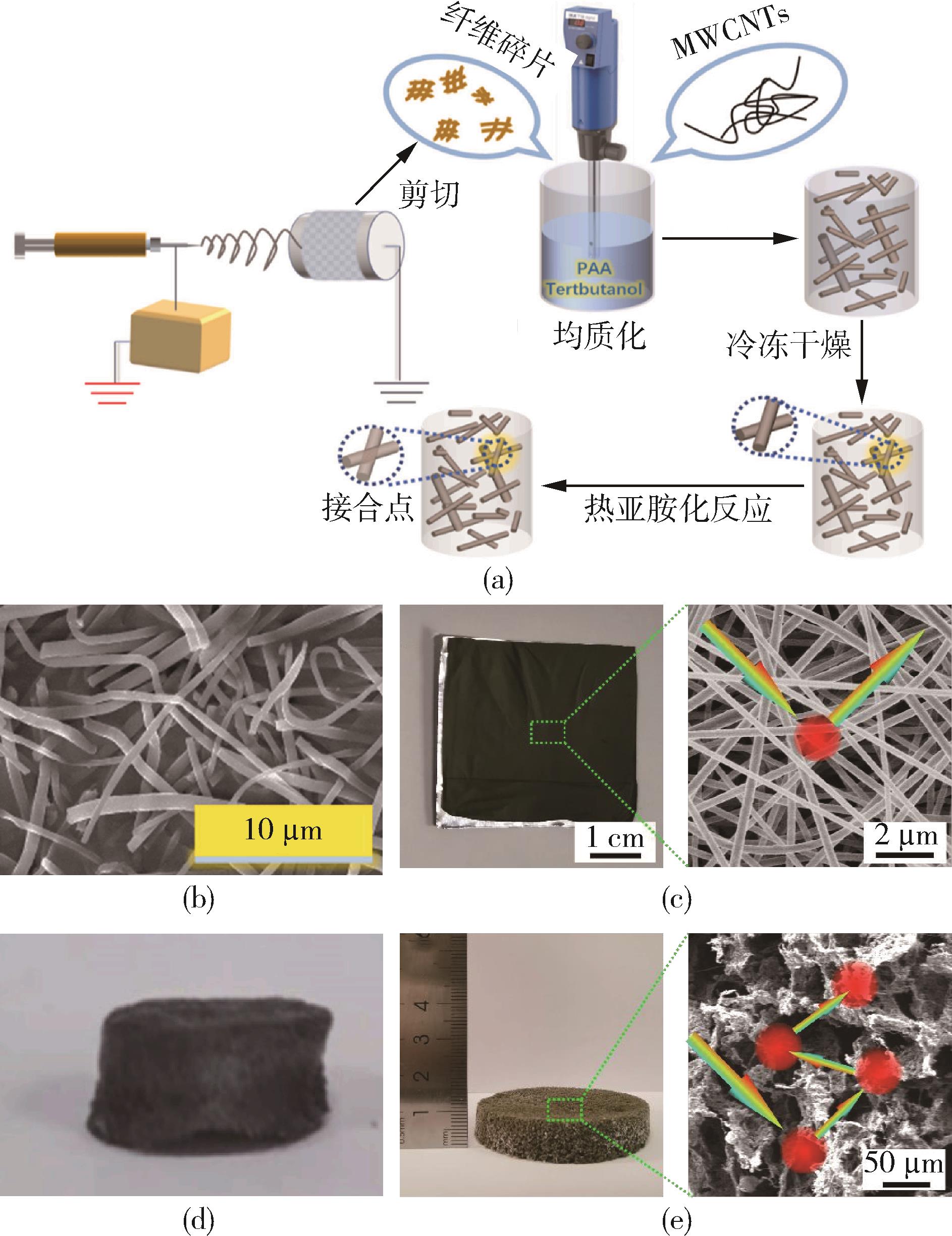

| 3D网孔纤维气凝胶 | PI/CNT纤维气凝胶[ | 静电纺丝+热亚胺化 | U=15 kV静电纺制得PI纤维,液氮冷却10 min后-20 ℃冷冻12 h,100、200、300 ℃热处理1 h。 | 三维网络结构,CNT均匀附着在纤维表面 | 2.08 | — |

| 全纤维气凝胶(AFA)[ | 静电纺丝+等离子体处理+电喷涂 | U=15 kV、D=15 cm、Q=0.8 mL/h静电纺制得AFA纤维,等离子体处理3 min和电喷涂30 min。 | 高孔隙率的三维多孔结构 | 1.43 | 86.5 |

| 纤维膜类型 | 纤维膜 | 制备方法 | 制备工艺及关键参数 | 纤维形貌 | 蒸发速率/ kg·m-2·h-1 | 光热转换效率/% |

|---|---|---|---|---|---|---|

| 单层纤维膜 | PDA@CNT/PU复合膜[ | 静电纺丝+原位聚合 | U=15 kV、Q=1.2 mL/h静电纺制得PU/CNT纤维后置于pH=8.5的PDA溶液超声水浴6 h。 | 分层纳米结构,微纳级孔互相粘连 | 1.44 | 90.1 |

| PAN@PPy复合膜[ | 静电纺丝+原位聚合 | U=22 kV、D=15 cm、Q=0.5 mL/h静电纺制得PPy纤维后,60 ℃干燥12 h使PAN聚合。 | 孔隙丰富、纤维表面粗糙 | 1.63 | 83.5 | |

| PVA/GO复合膜[ | 静电纺丝法+热处理 | U=15 kV、D=15 cm、Q=0.7 mL/h静电纺制得PVA/GO纤维,180 ℃热处理30 min。 | 介孔丰富、密度低 | 1.42 | 94.2 | |

| Janus结构纤维膜 | PPG@PU/PDMS@PU⁃CNTs复合膜[ | 两步静电纺丝 | U=12 kV、D=15 cm、Q=0.5 mL/h静电纺制备PPG@PU纤维膜,U=10 kV、D=15 cm、Q=1.8 mL/h静电纺制备PDMS@PU⁃CNTs。 | 三维微孔结构,纤维膜界面紧密连接 | 1.34 | — |

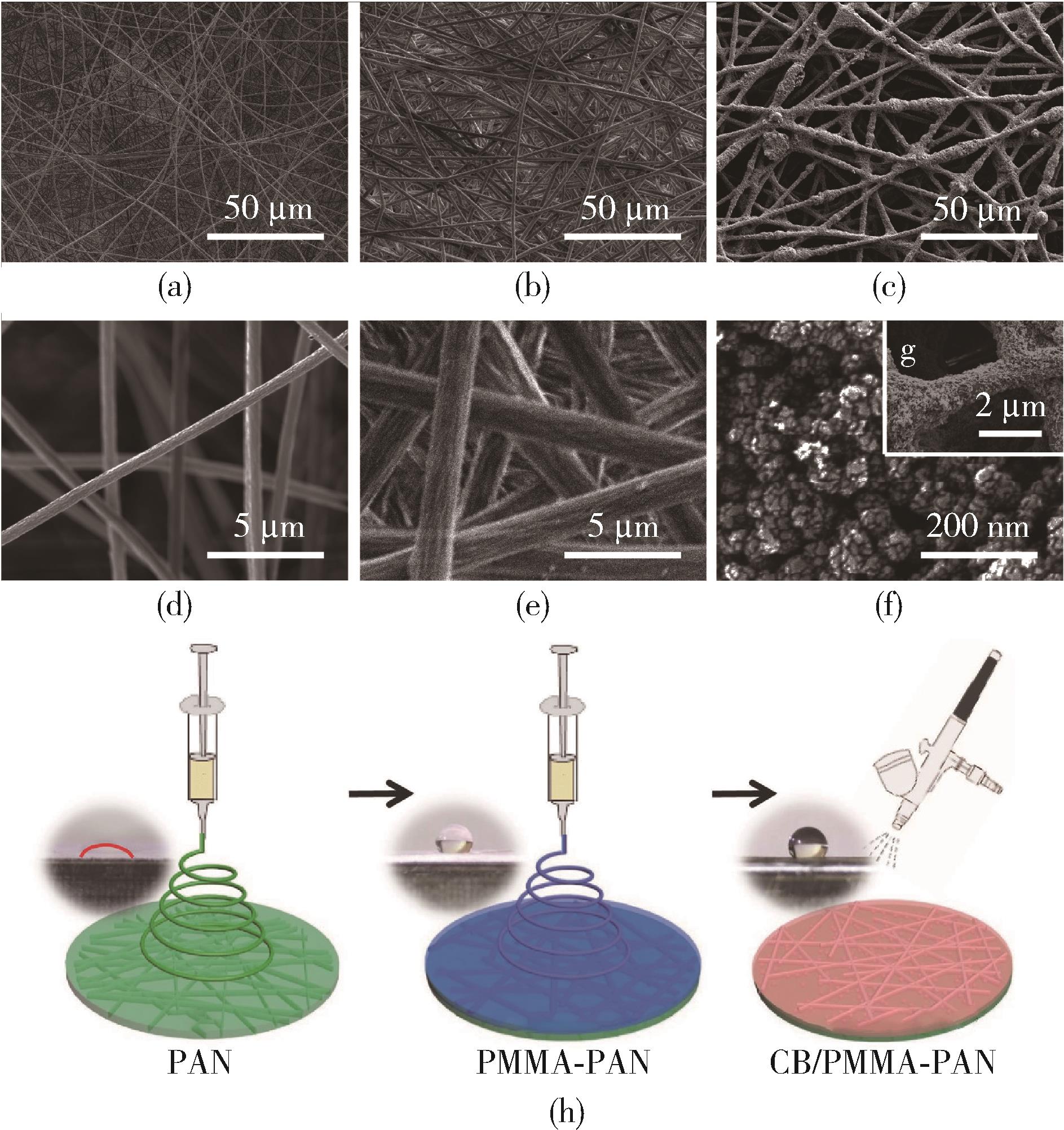

| PMMA/PAN/CB复合膜[ | 静电纺丝+喷涂沉积 | 在以U=14 kV、D=15 cm、Q=1.6 mL/h静电纺制得的PAN纤维膜上纺PMMA纤维膜(U=15 kV、D=15 cm、Q=3 mL/h),CB悬浮液喷涂至膜表面。 | 高度开放的三维微孔纳米纤维结构 | 1.30 | 72.0 | |

| CA/PAN/CNT复合膜[ | 静电纺丝+沉积 | 在以U=25 kV、D=15 cm、Q=1.0 mL/h静电纺制得的CA纤维膜上纺PAN纤维膜(U=18 kV、D=10 cm、Q=3 mL/h),CNT喷涂沉积在PAN膜表面。 | 无序填充的无纺布结构,碳纳米管附着在纤维表面 | 1.94 | 92.7 | |

| TPC/CB复合膜[ | 静电纺丝+涂覆 | U=14 kV、D=28 cm、Q=0.5 mL/h静电纺制得TPC纤维膜,通过真空过滤和干燥涂覆上CB。 | 多孔胞腔结构,CB附着在纤维表面 | 1.80 | 97.2 | |

| 3D网孔纤维气凝胶 | PI/CNT纤维气凝胶[ | 静电纺丝+热亚胺化 | U=15 kV静电纺制得PI纤维,液氮冷却10 min后-20 ℃冷冻12 h,100、200、300 ℃热处理1 h。 | 三维网络结构,CNT均匀附着在纤维表面 | 2.08 | — |

| 全纤维气凝胶(AFA)[ | 静电纺丝+等离子体处理+电喷涂 | U=15 kV、D=15 cm、Q=0.8 mL/h静电纺制得AFA纤维,等离子体处理3 min和电喷涂30 min。 | 高孔隙率的三维多孔结构 | 1.43 | 86.5 |

| 碳基纤维膜 | 纤维膜 特性 | 光热吸收体 结构 | 光源和 功率 | 光源功率/ W·cm-1 | 吸光波长/ nm | 蒸发速率/kg·m-2·h-1 | 光热转换 效率/% | 静电纺纤维膜制备参数 | 应用 |

|---|---|---|---|---|---|---|---|---|---|

| Janus PAN/CNT/CA复合膜[ | CNT/CA疏水,PAN亲水 | 搭桥式 | 太阳光 | 1 | 250~2 500 | 1.94 | 92.7 | CA纤维膜:U=25 kV、D=15 cm、Q=1.0 mL/h;PAN纤维膜:U=18 kV、D=10 cm、Q=3 mL/h | 海水淡化、光热发电、污水处理 |

| Janus TPC/CB复合膜[ | CB疏水,TPC亲水 | 自漂浮 | 太阳光 | 1 | 200~2 500 | 1.80 | 97.2 | TPC纤维膜:U=14 kV、D=28 cm、Q=0.5 mL/h | 海水淡化 |

| PAN/rGO复合膜[ | 亲水 | 加PS泡沫 | 太阳光 | 1 | 350~2 500 | 1.46 | 89.4 | PAN纤维膜:U=15 kV、Q=0.7 mL/h | 海水淡化 |

| PAN/CNT复合膜[ | 亲水,柔性可清洗 | 加PS泡沫 | 太阳光 | 1 | 350~2 500 | 1.44 | 90.8 | PAN纤维膜:U=12 kV、D=15 cm、Q=0.5 mL/h | 海水淡化 |

| PU/PDA@CNT复合膜[ | 亲水疏油,拉伸性能好 | 加PS泡沫 | — | — | — | 1.44 | 90.1 | PU纤维膜:U=15 kV、Q=1.2 mL/h | 含油污水净化 |

| PVA/GO复合膜[ | 亲水 | 自漂浮 | — | — | — | 1.42 | 94.2 | PVA纤维膜:U=15 kV、D=15 cm、Q=0.7 mL/h | 海水淡化 |

| PAN/SiO2/MWCNTs⁃COOH复合膜[ | 亲水,热稳定性好 | 加PS泡沫 | 太阳光 | 1 | 300~2 500 | 1.28 | 82.5 | PAN纤维膜:U=10 kV、D=10 cm、Q=0.7 mL/h | 海水淡化 |

| PVDF/CB/PAN复合膜[ | CB/PAN亲水,PVDF疏水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.20 | 82.0 | — | 海水淡化、水净化处理 |

| PAN@PPy复合膜[ | 亲水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.63 | 83.5 | PAN纤维膜:U=22 kV、D=15 cm、Q=0.5 mL/h | 污水处理 海水淡化 |

| Janus PAN/CB/PMMA复合膜[ | CB/PMMA疏水,PAN亲水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.30 | 72.0 | PAN纤维膜:U=15 kV、D=15 cm、Q=3 mL/h | 海水淡化 |

| PLA/中华墨[ | 亲水 | 加PS泡沫 | 太阳光 | 1 | 190~1 100 | 1.29 | 81.0 | PLA纤维膜:熔体电纺U=35 kV、D=7 cm、T=160 ℃ | 海水淡化 |

| PIfAs/CNT气凝胶[ | 亲水 | 加PS泡沫 | 太阳光 | 1 | 250~2 500 | 2.08 | — | PI纤维膜:溶体电纺U=15 kV | 海水淡化 |

| 碳基纤维膜 | 纤维膜 特性 | 光热吸收体 结构 | 光源和 功率 | 光源功率/ W·cm-1 | 吸光波长/ nm | 蒸发速率/kg·m-2·h-1 | 光热转换 效率/% | 静电纺纤维膜制备参数 | 应用 |

|---|---|---|---|---|---|---|---|---|---|

| Janus PAN/CNT/CA复合膜[ | CNT/CA疏水,PAN亲水 | 搭桥式 | 太阳光 | 1 | 250~2 500 | 1.94 | 92.7 | CA纤维膜:U=25 kV、D=15 cm、Q=1.0 mL/h;PAN纤维膜:U=18 kV、D=10 cm、Q=3 mL/h | 海水淡化、光热发电、污水处理 |

| Janus TPC/CB复合膜[ | CB疏水,TPC亲水 | 自漂浮 | 太阳光 | 1 | 200~2 500 | 1.80 | 97.2 | TPC纤维膜:U=14 kV、D=28 cm、Q=0.5 mL/h | 海水淡化 |

| PAN/rGO复合膜[ | 亲水 | 加PS泡沫 | 太阳光 | 1 | 350~2 500 | 1.46 | 89.4 | PAN纤维膜:U=15 kV、Q=0.7 mL/h | 海水淡化 |

| PAN/CNT复合膜[ | 亲水,柔性可清洗 | 加PS泡沫 | 太阳光 | 1 | 350~2 500 | 1.44 | 90.8 | PAN纤维膜:U=12 kV、D=15 cm、Q=0.5 mL/h | 海水淡化 |

| PU/PDA@CNT复合膜[ | 亲水疏油,拉伸性能好 | 加PS泡沫 | — | — | — | 1.44 | 90.1 | PU纤维膜:U=15 kV、Q=1.2 mL/h | 含油污水净化 |

| PVA/GO复合膜[ | 亲水 | 自漂浮 | — | — | — | 1.42 | 94.2 | PVA纤维膜:U=15 kV、D=15 cm、Q=0.7 mL/h | 海水淡化 |

| PAN/SiO2/MWCNTs⁃COOH复合膜[ | 亲水,热稳定性好 | 加PS泡沫 | 太阳光 | 1 | 300~2 500 | 1.28 | 82.5 | PAN纤维膜:U=10 kV、D=10 cm、Q=0.7 mL/h | 海水淡化 |

| PVDF/CB/PAN复合膜[ | CB/PAN亲水,PVDF疏水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.20 | 82.0 | — | 海水淡化、水净化处理 |

| PAN@PPy复合膜[ | 亲水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.63 | 83.5 | PAN纤维膜:U=22 kV、D=15 cm、Q=0.5 mL/h | 污水处理 海水淡化 |

| Janus PAN/CB/PMMA复合膜[ | CB/PMMA疏水,PAN亲水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.30 | 72.0 | PAN纤维膜:U=15 kV、D=15 cm、Q=3 mL/h | 海水淡化 |

| PLA/中华墨[ | 亲水 | 加PS泡沫 | 太阳光 | 1 | 190~1 100 | 1.29 | 81.0 | PLA纤维膜:熔体电纺U=35 kV、D=7 cm、T=160 ℃ | 海水淡化 |

| PIfAs/CNT气凝胶[ | 亲水 | 加PS泡沫 | 太阳光 | 1 | 250~2 500 | 2.08 | — | PI纤维膜:溶体电纺U=15 kV | 海水淡化 |

| 纤维膜 | 纤维膜 特性 | 光热吸收体结构 | 光源 | 光源功率/W·cm-1 | 吸光波长/nm | 蒸发速率/ kg·m-2·h-1 | 光热转换 效率/(%) | 静电纺纤维膜制备参数 | 应用 |

|---|---|---|---|---|---|---|---|---|---|

| PVDF/Ag复合膜[ | 疏水 | 自漂浮 | 紫外光 | 50 | 400 | 2.50 | 53 | PVDF纤维膜:U=25 kV、D=15 cm、Q=0.3 mL/h | 水净化、 海水淡化 |

| PU/Al复合膜[ | 无 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.72 | 89 | PU纤维膜:U=20 kV、D=10 cm、Q=0.1 mL/h | 海水淡化 |

| PNIPAM/Fe3O4复合膜[ | 亲水 | 加PS 泡沫 | 太阳光 | 1 | 250~2 500 | 1.76 | — | — | 超咸水淡化 |

| PVP/Ag/Cu2O复合膜[ | 无 | 加PS 泡沫 | 太阳光 | 1 | 250~2 000 | 1.35 | — | PVP纤维膜:U= 15 kV、D=15 cm | 水净化、 海水淡化 |

| PS/Au复合膜[ | 亲水 | 加非织 造布 | 太阳光 | 1 | 400~1 000 | 1.85 | 99 | PS纤维膜:U=17 kV、D=15 cm、Q=1 mL/h | 海水淡化、 污水处理 |

| 纤维膜 | 纤维膜 特性 | 光热吸收体结构 | 光源 | 光源功率/W·cm-1 | 吸光波长/nm | 蒸发速率/ kg·m-2·h-1 | 光热转换 效率/(%) | 静电纺纤维膜制备参数 | 应用 |

|---|---|---|---|---|---|---|---|---|---|

| PVDF/Ag复合膜[ | 疏水 | 自漂浮 | 紫外光 | 50 | 400 | 2.50 | 53 | PVDF纤维膜:U=25 kV、D=15 cm、Q=0.3 mL/h | 水净化、 海水淡化 |

| PU/Al复合膜[ | 无 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.72 | 89 | PU纤维膜:U=20 kV、D=10 cm、Q=0.1 mL/h | 海水淡化 |

| PNIPAM/Fe3O4复合膜[ | 亲水 | 加PS 泡沫 | 太阳光 | 1 | 250~2 500 | 1.76 | — | — | 超咸水淡化 |

| PVP/Ag/Cu2O复合膜[ | 无 | 加PS 泡沫 | 太阳光 | 1 | 250~2 000 | 1.35 | — | PVP纤维膜:U= 15 kV、D=15 cm | 水净化、 海水淡化 |

| PS/Au复合膜[ | 亲水 | 加非织 造布 | 太阳光 | 1 | 400~1 000 | 1.85 | 99 | PS纤维膜:U=17 kV、D=15 cm、Q=1 mL/h | 海水淡化、 污水处理 |

| 纤维膜 | 纤维膜 特性 | 光热吸收体结构 | 光源 | 光源功率/ W·cm-1 | 吸光波长 | 蒸发速率/ kg·m-2·h-1 | 光热转换 效率/% | 静电纺纤维膜制备参数 | 应用 |

|---|---|---|---|---|---|---|---|---|---|

| rTAC/Rb x WO3复合膜[ | 疏水 | 自漂浮 | 近红外光 | 0.217 | 380~2 200 | 3.13 | 90.4 | rTAC纤维膜:U=15 kV、 D=15 cm、Q=0.5 mL/h | 海水淡化 |

| PLA/WO2.72复合膜[ | 疏水 | 自漂浮 | 红外光 | 0.294 | 780~2 500 | 3.81 | 81.4 | PLA纤维膜:电场强度 4 kV/cm、T=260°C | 海水淡化、 水蒸发 |

| PAN@CuS复合膜[ | 亲水 | PS泡沫 | 太阳光 | 1 | 200~2 500 | 2.27 | 83.9 | PAN纤维膜:U=22 kV、 D=15 cm、Q=1 mL/h | 海水淡化、 废水净化 |

| PAN/Co3S4复合膜[ | 亲水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.26 | 86.5 | PAN纤维膜:U=22 kV | 海水淡化 |

| 纤维膜 | 纤维膜 特性 | 光热吸收体结构 | 光源 | 光源功率/ W·cm-1 | 吸光波长 | 蒸发速率/ kg·m-2·h-1 | 光热转换 效率/% | 静电纺纤维膜制备参数 | 应用 |

|---|---|---|---|---|---|---|---|---|---|

| rTAC/Rb x WO3复合膜[ | 疏水 | 自漂浮 | 近红外光 | 0.217 | 380~2 200 | 3.13 | 90.4 | rTAC纤维膜:U=15 kV、 D=15 cm、Q=0.5 mL/h | 海水淡化 |

| PLA/WO2.72复合膜[ | 疏水 | 自漂浮 | 红外光 | 0.294 | 780~2 500 | 3.81 | 81.4 | PLA纤维膜:电场强度 4 kV/cm、T=260°C | 海水淡化、 水蒸发 |

| PAN@CuS复合膜[ | 亲水 | PS泡沫 | 太阳光 | 1 | 200~2 500 | 2.27 | 83.9 | PAN纤维膜:U=22 kV、 D=15 cm、Q=1 mL/h | 海水淡化、 废水净化 |

| PAN/Co3S4复合膜[ | 亲水 | 自漂浮 | 太阳光 | 1 | 250~2 500 | 1.26 | 86.5 | PAN纤维膜:U=22 kV | 海水淡化 |

| 1 | 陈二烈. 全球淡水资源危机愈演愈烈[J]. 生态经济, 2022, 38(10): 5⁃8. |

| CHEN E L. The global freshwater crisis is getting worse [J]. Ecological Economy, 2022, 38(10): 5⁃8. | |

| 2 | 郑智颖, 李凤臣, 李倩, 等. 海水淡化技术应用研究及发展现状[J]. 科学通报, 2016, 6(21): 2 344⁃2 370. |

| ZHENG Z Y, LI F C, LI Q, et al. State⁃of⁃the⁃art of R&D on seawater desalination technology[J]. Science China Press, 2016, 6(21): 2 344⁃2 370. | |

| 3 | TAO P, NI G, SONG C, et al. Solar⁃driven interfacial evaporation[J]. Nature Energy, 2018, 3(12): 1 031⁃1 041. |

| 4 | SALEEM H, TRABZON L, KILIC A, et al. Recent advances in nanofibrous membranes: Production and applications in water treatment and desalination [J]. Desalination, 2020, 478: 114178. |

| 5 | ZHAO J, LIU Z, LOW S C, et al. Electrospinning technique meets solar energy: electrospun nanofiber⁃based evaporation systems for solar steam generation [J]. Advanced Fiber Materials, 2023: 1⁃31. |

| 6 | RODRíGUEZ⁃TOBíAS H, MORALES G, GRANDE D. Comprehensive review on electrospinning techniques as versatile approaches toward antimicrobial biopolymeric composite fibers [J]. Materials Science and Engineering: C, 2019, 101: 306⁃322. |

| 7 | HAMEED R M A, ZOULI N, ABUTALEB A, et al. Improving water desalination performance of electrospun carbon nanofibers by supporting with binary metallic carbide nanoparticles [J]. Ceramics International, 2022, 48(4): 4 741⁃4 753. |

| 8 | WU D, LIANG J, ZHANG D, et al. Solar evaporation and electricity generation of porous carbonaceous membrane prepared by electrospinning and carbonization [J]. Solar Energy Materials and Solar Cells, 2020, 215: 110591. |

| 9 | HUANG C, THOMAS N L. Fabrication of porous fibers via electrospinning: strategies and applications [J]. Polymer Reviews, 2020, 60(4): 595⁃647. |

| 10 | 何雪涛, 张毅, 莫振宇, 等. 熔体微分静电纺PBAT纤维膜的制备工艺研究 [J]. 中国塑料, 2022, 36(12): 1⁃5. |

| HE X T, ZHANG Y, MO Z Y, et al. Preparation process of PBAT fiber membrane by melt differential electrospinning [J]. China Plastics, 2022, 36(12): 1⁃5. | |

| 11 | 孙少阳, 申莹, 王容容, 等. 静电纺聚乳酸纳米纤维的制备及其孔结构调控 [J]. 中国塑料, 2023, 37(4): 67⁃73. |

| SUN S Y, SHEN Y, WANG R R, et al. Preparation and pore structure regulation of electrospun polylactic acid nanofibers [J]. China Plastics, 2023, 37(4): 67⁃73. | |

| 12 | KOU H, LIU Z, ZHU B, et al. Recyclable CNT⁃coupled cotton fabrics for low⁃cost and efficient desalination of seawater under sunlight [J]. Desalination, 2019, 462: 29⁃38. |

| 13 | HE M, LIU H, WANG L, et al. One⁃step fabrication of a stretchable and anti⁃oil⁃fouling nanofiber membrane for solar steam generation [J]. Materials Chemistry Frontiers, 2021, 5(9): 3 673⁃3 680. |

| 14 | REN X, CUI S, GUAN J, et al. PAN@PPy nanofibrous membrane with core⁃sheath structure for solar water evaporation [J]. Materials Letters, 2022, 313: 131807. |

| 15 | GUO X, GAO H, WANG S, et al. Scalable, flexible and reusable graphene oxide⁃functionalized electrospun nanofibrous membrane for solar photothermal desalination [J]. Desalination, 2020, 488: 114535. |

| 16 | LIU H, GU J, LIU Y, et al. Reconfiguration and self⁃healing integrated Janus electrospinning nanofiber membranes for durable seawater desalination [J]. Nano Research, 2023, 16(1): 489⁃495. |

| 17 | XU W, HU X, ZHUANG S, et al. Flexible and salt resistant janus absorbers by electrospinning for stable and efficient solar desalination [J]. Advanced Energy Materials, 2018, 8(14): 1702884. |

| 18 | DONG X, LI H, GAO L, et al. Janus fibrous mats based suspended type evaporator for salt resistant solar desalination and salt recovery [J]. Small, 2022, 18(13): 2107156. |

| 19 | LI S, QIU F, XIA Y, et al. Integrating a self⁃floating Janus TPC@CB sponge for efficient solar⁃driven interfacial water evaporation [J]. ACS Applied Materials & Interfaces, 2022, 14(17): 19 409⁃19 418. |

| 20 | REN Y, LIAN R, LIU Z, et al. CNT/polyimide fiber⁃based 3D photothermal aerogel for high⁃efficiency and long⁃lasting seawater desalination [J]. Desalination, 2022, 535: 115836. |

| 21 | LI H, WEN H, LI J, et al. Doping AIE photothermal molecule into all⁃fiber aerogel with self⁃pumping water function for efficiency solar steam generation [J]. ACS Applied Materials & Interfaces, 2020, 12(23): 26 033⁃26 040. |

| 22 | 徐炜超. Janus吸收体在太阳能海水淡化方面的研究 [D]. 江苏省: 南京大学, 2018. |

| 23 | MU P, BAI W, FAN Y, et al. Conductive hollow kapok fiber⁃PPy monolithic aerogels with excellent mechanical robustness for efficient solar steam generation [J]. Journal of Materials Chemistry A, 2019, 7(16): 9 673⁃9 679. |

| 24 | 丁彬. 功能微纳米聚合物纤维材料 [J]. 高分子学报, 2019, 50(8): 764⁃774. |

| DING B. Functional polymeric micro/nano⁃fibrous materials [J]. Acta Polymerica Sinica, 2019, 50(8): 764⁃774. | |

| 25 | 党箐, 张豪, 周子权, 等. 基于气凝胶的界面太阳能光蒸汽转化技术的研究进展 [J]. 功能材料与器件学报, 2022, 28(3): 212⁃231. |

| DANG J, ZHANG H, ZHOU Z Q, et al. Research progress of aerogels for interfacial solar⁃vapor conversion technology [J]. Journal of Functional Materials and Devices, 2022, 28(3): 212⁃231. | |

| 26 | 汤勇, 于佳栋, 余树东, 等. 界面太阳能蒸汽发生系统的研究进展与展望 [J]. 机械工程学报, 2022, 58(6): 221⁃241. |

| TANG Y, YU J, YU S, et al. Research progress and prospect on interfacial solar vapor generation system [J]. Journal of Mechanical Engineering, 2022, 58(6): 221⁃241. | |

| 27 | LIU G, XU J, WANG K. Solar water evaporation by black photothermal sheets [J]. Nano Energy, 2017, 41: 269⁃284. |

| 28 | CHEN C, KUANG Y, HU L. Challenges and opportunities for solar evaporation [J]. Joule, 2019, 3(3): 683⁃718. |

| 29 | FAN X, LV B, XU Y, et al. Electrospun reduced graphene oxide/polyacrylonitrile membrane for high⁃performance solar evaporation [J]. Solar Energy, 2020, 209: 325⁃333. |

| 30 | ZHU B, KOU H, LIU Z, et al. Flexible and washable CNT⁃embedded PAN nonwoven fabrics for solar⁃enabled evaporation and desalination of seawater [J]. ACS Applied Materials & Interfaces, 2019, 11(38): 35 005⁃35 014. |

| 31 | QI Q, WANG W, WANG Y, et al. Robust light⁃driven interfacial water evaporator by electrospinning SiO2/MWCNTs⁃COOH/PAN photothermal fiber membrane [J]. Separation and Purification Technology, 2020, 239: 116595. |

| 32 | GAO T, LI Y, CHEN C, et al. Architecting a floatable, durable, and scalable steam generator: hydrophobic/hydrophilic bifunctional structure for solar evaporation enhancement [J]. Small Methods, 2019, 3(2): 1800176. |

| 33 | DING Q, GUAN C, LI H, et al. Solar⁃driven interfacial evaporation based on double⁃layer polylactic acid fibrous membranes loading Chinese ink nanoparticles [J]. Solar Energy, 2020, 195: 636⁃643. |

| 34 | YAN J, SU Q, XIAO W, et al. A review of nanofiber membranes for solar interface evaporation [J]. Desalination, 2022, 531: 115686. |

| 35 | YE H, LI X, DENG L, et al. Silver nanoparticle⁃enabled photothermal nanofibrous membrane for light⁃driven membrane distillation [J]. Industrial & Engineering Chemistry Research, 2019, 58(8): 3 269⁃3 281. |

| 36 | LI L, WANG J, JIAO B, et al. Broadband absorption of electrospun scaffold⁃assisted self⁃assembled metal nanostructures for solar⁃powered water evaporation [J]. Organic Electronics, 2023, 114: 106727. |

| 37 | HIGASHI S, MATSUI T, BENIYA A. Rapid solar heating of antimicrobial Ag and Cu2O nanostructured plasmonic textile for clean water production [J]. ACS Applied Materials & Interfaces, 2022, 14(35): 40 214⁃40 222. |

| 38 | CHEN G, JIANG Z, LI A, et al. Structural and compositional modulation of porous carbon for high⁃performance photothermal water evaporation [J]. ACS Sustainable Chemistry & Engineering, 2022, 10(12): 4 013⁃4 021. |

| 39 | LI H N, YANG H C, ZHU C Y, et al. A self⁃descaling Janus nanofibrous evaporator enabled by a “moving interface” for durable solar⁃driven desalination of hypersaline water [J]. Journal of Materials Chemistry A, 2022, 10(39): 20 856⁃20 865. |

| 40 | NASEEM S, WU C⁃M, CHALA T F. Photothermal⁃responsive tungsten bronze/recycled cellulose triacetate porous fiber membranes for efficient light⁃driven interfacial water evaporation [J]. Solar Energy, 2019, 194: 391⁃399. |

| 41 | CHALA T F, WU C M, CHOU M H, et al. Melt electrospun reduced tungsten oxide/polylactic acid fiber membranes as a photothermal material for light⁃driven interfacial water evaporation [J]. ACS Applied Materials & Interfaces, 2018, 10(34): 28 955⁃28 962. |

| 42 | YE M, JIA J, WU Z, et al. Synthesis of black TiO x nanoparticles by Mg reduction of TiO2 nanocrystals and their application for solar water evaporation [J]. Advanced Energy Materials, 2017, 7(4): 1601811. |

| 43 | LIU Z, ZHOU Z, WU N, et al. Hierarchical photothermal fabrics with low evaporation enthalpy as heliotropic evaporators for efficient, continuous, salt⁃free desalination [J]. ACS Nano, 2021, 15(8): 13 007⁃13 018. |

| 44 | YIN X, ZHANG Y, XU X, et al. Bilayer fiber membrane electrospun from MOF derived Co3S4 and PAN for solar steam generation induced sea water desalination [J]. Journal of Solid State Chemistry, 2021, 303: 122423. |

| [1] | CHENG En, YE Donglei, CHENG Debao, TIAN Huafeng, ZHAO Xiaoying, XIANG Aimin. Gelatin⁃based electrospun nanofibers and their applications [J]. China Plastics, 2024, 38(4): 103-108. |

| [2] | TAN Jing, WANG Zhi, WANG Shuo, FU Hongyan, LI Changjin, LI Haoyi, YANG Weimin, ZHANG Yang. Study on toughening modification of poly(lactic acid) melt differential electrospun fiber membrane by dendrimer [J]. China Plastics, 2024, 38(2): 7-13. |

| [3] | LI Jie, LU Yiyi, SHI Wentian, GUO Yunjie, WANG Yuke. Preparation and oil⁃water separation performance of PDMS/PVDF electrospun membranes [J]. China Plastics, 2024, 38(1): 28-34. |

| [4] | WANG Yuwei, XIAO Runxiang, ZHANG Hongkai, GUAN Wenjin, DENG Yafeng. Research progress in nanofiber⁃based air filtration materials [J]. China Plastics, 2023, 37(9): 115-124. |

| [5] | GUAN Guotao, LIU Chenze, HE Shiquan, SONG Chaoyang, ZHANG Xiang, ZHAO Na, WANG Chao. Preparation and properties of antibacterial biodegradable poly (lactic acid) membrane [J]. China Plastics, 2023, 37(9): 8-13. |

| [6] | WANG Rongrong, JIANG Tao, SUN Shaoyang, ZHOU Zhou, WANG Xiang, SHEN Ying, XING Jian. Preparation and performance of electrospun polyimide/multi⁃wall carbon nanotubes hybrid nanofibers [J]. China Plastics, 2023, 37(12): 23-28. |

| [7] | LI Haoyi, WANG Yiming, DING Xi, ZHANG Yi, BAI Jingyu, LI Feifei, ZHANG Yueyong, YANG Weimin. Research progress in electrospinning drug loading and its applications [J]. China Plastics, 2023, 37(12): 60-69. |

| [8] | . Preparation and performance of electrospun polyimide/multi-wall carbon nanotubes hybrid nanofibers [J]. , 2023, 37(12): 23-28. |

| [9] | DU Qing, HE Yi, YU Tanjing, LAN Yanjiao, ZHAO Yanzhi, ZHOU Juying. Preparation and characterization of oriented thermoplastic polyolefin/PAN/ MWCNT composites [J]. China Plastics, 2022, 36(8): 49-55. |

| [10] | ZHOU Shuyi, ZHU Min, LIU Yiying, CAO Shuhui, CAI Qixuan, NIE Hui, ZHANG Yuxia, ZHOU Hongfu. Research progress in polymer⁃based hemostatic materials [J]. China Plastics, 2022, 36(7): 74-84. |

| [11] | HE Xuetao, ZHANG Yi, MO Zhenyu, LI Changjin, WANG Shuo, YANG Weimin, LI Haoyi. Preparation process of PBAT fiber membrane by melt differential electrospinning [J]. China Plastics, 2022, 36(12): 1-5. |

| [12] | LI Juan, WANG Yaqiao. Effect of polytetrafluoroethylene fibrillation on the foaming behavior of TPEE/PTFE composites [J]. China Plastics, 2022, 36(12): 38-43. |

| [13] | ZHANG Kehong, CHU Chengxiang, LIU Xiaolong. Preparation and properties of epoxy resin/cellulose nanofiber composites [J]. China Plastics, 2022, 36(11): 67-72. |

| [14] | ZHANG Xiang, WU Xian′an, LI Changjin, DU Changbiao, LI Haoyi, JIAO Zhiwei, YANG Weimin, ZHANG Yang. Research progress in preparation and applications of polymer nanofibers based on micro⁃nano lamination technology [J]. China Plastics, 2022, 36(10): 159-166. |

| [15] | AN Ying, LIU Yuliang, TAN Jing, YANG Weiming, YAN Hua, LI Haoyi. Research progress in polymer centrifugal electrospinning [J]. China Plastics, 2022, 36(1): 172-177. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||