京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (12): 60-65.DOI: 10.19491/j.issn.1001-9278.2024.12.010

• Materials and Properties • Previous Articles Next Articles

REN Siying, DU Jiahui, SUN Tao, WU Yifeng, GUO Jiushi, YUN Xueyan( )

)

Received:2024-04-02

Online:2024-12-26

Published:2024-12-25

CLC Number:

REN Siying, DU Jiahui, SUN Tao, WU Yifeng, GUO Jiushi, YUN Xueyan. Thermal, mechanical and barrier properties of PLLA/PDBI blend films[J]. China Plastics, 2024, 38(12): 60-65.

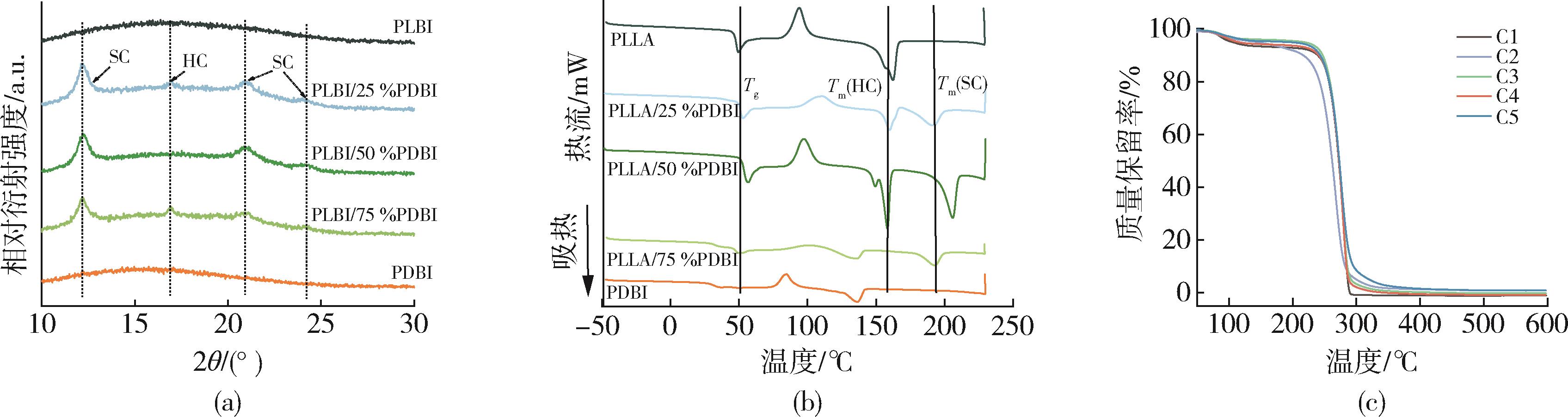

| 样品 | Tg/℃ | Tc/℃ | ∆Hc/J·g-1 | Tm1/℃ | ∆Hm1/J·g-1 | Tm2/℃ | ∆Hm2/J·g-1 | XHC/% | XSC/% | Xtotal/ % |

|---|---|---|---|---|---|---|---|---|---|---|

| PLLA | 45.78 | 94.06 | 19.89 | 162.35 | 22.13 | - | - | 2.41 | 0 | 2.41 |

| PLLA/PDBI25 | 51.38 | 110.69 | 10.96 | 159.95 | 11.49 | 191.95 | 14.58 | 0.82 | 2.92 | 3.74 |

| PLLA/PDBI50 | 53.59 | 97.46 | 12.75 | 158.29 | 12.76 | 205.97 | 23.85 | 0.60 | 8.52 | 9.12 |

| PLLA/PDBI75 | 46.45 | 101.68 | 6.497 | 135.87 | 9.024 | 193.27 | 8.740 | 2.59 | 1.97 | 4.56 |

| PDBI | 31.55 | 84.64 | 18.74 | 136.39 | 21.31 | - | - | 2.76 | 0 | 2.76 |

| 样品 | Tg/℃ | Tc/℃ | ∆Hc/J·g-1 | Tm1/℃ | ∆Hm1/J·g-1 | Tm2/℃ | ∆Hm2/J·g-1 | XHC/% | XSC/% | Xtotal/ % |

|---|---|---|---|---|---|---|---|---|---|---|

| PLLA | 45.78 | 94.06 | 19.89 | 162.35 | 22.13 | - | - | 2.41 | 0 | 2.41 |

| PLLA/PDBI25 | 51.38 | 110.69 | 10.96 | 159.95 | 11.49 | 191.95 | 14.58 | 0.82 | 2.92 | 3.74 |

| PLLA/PDBI50 | 53.59 | 97.46 | 12.75 | 158.29 | 12.76 | 205.97 | 23.85 | 0.60 | 8.52 | 9.12 |

| PLLA/PDBI75 | 46.45 | 101.68 | 6.497 | 135.87 | 9.024 | 193.27 | 8.740 | 2.59 | 1.97 | 4.56 |

| PDBI | 31.55 | 84.64 | 18.74 | 136.39 | 21.31 | - | - | 2.76 | 0 | 2.76 |

| 样品 | 拉伸强度/MPa | 断裂伸长率/ % | 弹性模量/ MPa |

|---|---|---|---|

| PLLA | 39.84±3.18 | 4.83±0.12 | 1 587.48±79.37 |

| PLLA/25 %PDBI | 35.49±1.07 | 8.47±3.13 | 1 258.76±54.13 |

| PLLA/50 %PDBI | 29.76±0.75 | 285.07±13.58 | 853.38±34.99 |

| PLLA/75 %PDBI | 29.93±1.15 | 3.07±0.58 | 927.64±47.31 |

| PDBI | 19.28±0.98 | 13.23±1.16 | 563.44±29.86 |

| 样品 | 拉伸强度/MPa | 断裂伸长率/ % | 弹性模量/ MPa |

|---|---|---|---|

| PLLA | 39.84±3.18 | 4.83±0.12 | 1 587.48±79.37 |

| PLLA/25 %PDBI | 35.49±1.07 | 8.47±3.13 | 1 258.76±54.13 |

| PLLA/50 %PDBI | 29.76±0.75 | 285.07±13.58 | 853.38±34.99 |

| PLLA/75 %PDBI | 29.93±1.15 | 3.07±0.58 | 927.64±47.31 |

| PDBI | 19.28±0.98 | 13.23±1.16 | 563.44±29.86 |

| 1 | 孙文潇, 杨 帆, 侯梦宗, 等. 环境中的微塑料污染及降解 [J]. 中国塑料, 2023, 37(11): 117⁃126. |

| SUN W X, YANG F, HOU M Z, et al. Microplastic pollution and degradation in the environment [J]. China Plastics, 2023,37(11): 117⁃126. | |

| 2 | Lei C, Xu W, Shi B,et al. Construction of cross⁃linked networks in polylactic acid biocomposites by using vegetable oil⁃modified collagen fibers for improving anti⁃stress relaxation and toughness[J].Industrial Crops & Products, 2024,210: 118160. |

| 3 | Shuo W, Baodong L, Yingying Q,et al. Effects of Processing Conditions and Plasticizing⁃Reinforcing Modification on the Crystallization and Physical Properties of PLA Films[J].Membranes,2021,11(8): 640⁃640. |

| 4 | 陈 婷, 王经逸, 曹长林,等. 聚乳酸增强增韧功能化改性研究进展[J].塑料科技,2023, 51(02): 114⁃119. |

| CHEN T, WANG J Y, CAO C L, et al. Research progress on enhanced toughening and functionalization modification of polylactic acid[J].Plastics Science and Technology,2023, 51(02): 114⁃119. | |

| 5 | Vijaya R, Boniface T, Shaik J. Nano⁃engineered eggshell toughened polylactic acid/aliphatic⁃aromatic copolyester flexible polymer blend [J].Abstracts of Papers of the American Chemical Society, 2016, 251. |

| 6 | 贾仕奎, 王 忠, 朱 艳,等. 聚乳酸/聚氨酯共混物的力学行为与形态研究[J].中国塑料, 2017,31(03): 35⁃39. |

| JIA S K, WANG Z, ZHU Y, et al. Mechanical behavior and morphology of polylactic acid/polyurethane blend[J].China Plastics, 2017, 31(03): 35⁃39. | |

| 7 | 张 禹, 何继敏, 周 麒, 等.PLA与PBAT共混改性研究进展[J].工程塑料,2023,51(10): 173⁃178. |

| ZHANG Y, HE J M, ZHOU Q, et al. Research progress on blending modification of PLA and PBAT[J].Engineering Plastics,2023,51(10): 173⁃178. | |

| 8 | 白佳鑫, 胡 健, 刘 博, 等. 高柔性PLLA/PBF共混膜的制备及性能[J].塑料,2023,52(03): 172⁃176+182. |

| BAI J X, HU J, LIU B, et al. Preparation and properties of highly flexible PLLA/PBF blend membrane[J].Plastics,2023,52(03): 172⁃176+182. | |

| 9 | 颜祥禹.PLA和PBST系列共混物的制备及性能研究[D].长春工业大学,2022. |

| 10 | 童敏杰, 马博谋, 刘 贵, 等.PBAT/PLLA/PDLA共混材料的结晶性能和耐热性能研究[J].东华大学学报(自然科学版),2023, 49(06): 43⁃52. |

| TONG M J, MA B M, LIU G, WANG X L, et al.Study on crystallization properties and heat resistance of PBAT/PLLA/PDLA blends[J].Journal of Donghua University(Natural Science Edition), 2023,49(06): 43⁃52. | |

| 11 | Li W, Cao J, Fu L, al et, Effect of stereo⁃complexation on crystallization behavior and barrier properties of poly⁃lactide[J].International journal of biological macromolecules, 2024,261(P2): 129 834. |

| 12 | Lizhi Y, Shihao D, Yue W, al et, Remarkably enhanced stereocomplex crystallization of high⁃molar⁃mass enantiomeric polylactide blends by adding double⁃grafted copolymers[J].International Journal of Biological Macromolecules, 2024,258(P1): 128919. |

| 13 | 张 玮, 白红伟,傅 强.分子链有序化混合对PLLA/PDLA共混物熔融稳定性的影响[J].塑料工业, 2021,49(08):57⁃60+65. |

| ZHANG W, BAI H W, FU Q. Effect of molecular chain ordering mixing on the melting stability of PLLA/PDLA blends[J].Plastics Industry, 2021,49(08): 57⁃60+65. | |

| 14 | Xiaolong S, Lihua F, Demei Y. Formation of Stereocomplex Crystal and Its Effect on the Morphology and Property of PDLA/PLLA Blends[J].Polymers, 2020, 12(11): 2 515. |

| 15 | 刘 博, 胡 健, 白佳鑫, 等.具有柔性的结晶性聚(L⁃乳酸)/聚衣康酸丁二醇酯共混薄膜的制备及力学和热学性能[J].高分子材料科学与工程, 2022,38(06): 63⁃70. |

| LIU B, HU J, BAI J X, et al. Preparation and mechanical and thermal properties of flexible crystalline poly(L⁃lactic acid)/polyyiconic acid butylene glycol blend film[J].Polymer Materials Science and Engineering, 2022, 38(06): 63⁃70. | |

| 16 | Loomis G J P P. Polylactide stereocomplexes[J]. 1990, 31: 55. |

| 17 | Fischer E, Sterzel H J, Zu Zf P G J K. Wegner, Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions[J]. 1973,251: 980⁃990. |

| 18 | 盛维琛, 谈 静, 陈剑峰, 等.乙氧(醚)化双酚A甲基丙烯酸双酯的烯硫醇反应及产物性能[J].塑料工业, 2022,50(S1): 100⁃104. |

| 19 | Hoogsteen W, Postema A, Pennings A, et al. Crystal structure, conformation and morphology of solution⁃spun poly (L⁃lactide) fibers[J]. 1990,23(2): 634⁃642. |

| 20 | Brizzolara D, Cantow H J, Diederichs K, et al.Mechanism of the stereocomplex formation between enantiomeric poly (lactide) s[J]. 1996,29(1): 191⁃197. |

| 21 | 景占鑫, 匡 倩, 李广瑞, 等.立构复合调控聚乳酸基材料性能及其应用研究进展[J].工程塑料应用,2023, 51(12): 156⁃164. |

| JING Z X, KUANG Q, LI G R, et al. Research progress on the regulation of properties and application of polylactic acid⁃based materials by stereostructural composites[J].Engineering Plastics Application,2023, 51(12): 156⁃164. |

| [1] | CUI Bao, YANG Jianjun, WU Qingyun, WU Mingyuan, ZHANG Jianan, LIU Jiuyi. Research Progress in blending modification of polylactic acid composites and their applications [J]. China Plastics, 2024, 38(9): 129-136. |

| [2] | DING Xinyi, DUN Dongxing, QIN Junxi, CHEN Yulei, HAN Yufei, ZHANG Yuxia, ZHOU Hongfu. Study on microstructure and properties of ST⁃NAB3 nucleating agent⁃modified chain⁃extended polylactic acid [J]. China Plastics, 2024, 38(9): 41-46. |

| [3] | DONG Guang, HOU Yangzhe, YUAN Hongyue, LIU Xianhu, PAN Yamin. Progress in porous poly(lactic acid) material and their structure and performance optimization [J]. China Plastics, 2024, 38(8): 132-140. |

| [4] | HE Hezhi, HUANG Zonghai, LAI Wen, XIONG Huawei. Preparation and properties of PLA/PBAT/CB antistatic packaging materials [J]. China Plastics, 2024, 38(7): 1-8. |

| [5] | HU Yongxiang, XIE Jiling, LI Weiming, ZHANG Lu, TANG Xianggang, LYU Yitong, SHEN Hongwang, JU Guannan. Effect of maleic anhydride graft⁃modified ground tire rubber on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 20-24. |

| [6] | WANG Jie, XIN Dehua, LI Hui, JIANG Hongshi, ZHOU Hongfu, ZHAO Jianguo. Effect of hybrid reinforcement of nanoclay and silica on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 43-48. |

| [7] | YANG Chaoyong, GUO Jinqiang, WANG Fuyu, ZHANG Yuxia. Effect of extrusion blowing process on microstructure and properties of PBAT/PLA blend [J]. China Plastics, 2024, 38(5): 82-87. |

| [8] | BO Haiwa, ZHAO Zhongguo, WANG Chouxuan, XUE Rong. Structural design and properties of PLA/CNTs conductive composites with high conductivity and low percolation [J]. China Plastics, 2024, 38(4): 13-18. |

| [9] | QI Shijie, YOU Xiangyu, WANG Ruichen, ZHOU Linfei, ZHANG Huijie. Preparation and properties of poly(lactic acid)/lignin blends with high lignin content [J]. China Plastics, 2024, 38(2): 45-51. |

| [10] | TAN Jing, WANG Zhi, WANG Shuo, FU Hongyan, LI Changjin, LI Haoyi, YANG Weimin, ZHANG Yang. Study on toughening modification of poly(lactic acid) melt differential electrospun fiber membrane by dendrimer [J]. China Plastics, 2024, 38(2): 7-13. |

| [11] | MA Xiuqing, LAO Zhichao, LI Mingqian, HAN Shuntao, HU Nan. Effect of 3D printing process parameters on mechanical properties of PLA/PTW blends [J]. China Plastics, 2024, 38(2): 70-75. |

| [12] | WANG Aohua, DUN Dongxing, MENG Ruijing, ZHANG Yuxia. Study on performance regulation of chain⁃extended poly(lactic acid) foams with diphenylhydrazide sebacic acid [J]. China Plastics, 2024, 38(11): 64-69. |

| [13] | CUI Chengzhi, CAO Jinxing, LIU Jianlan, ZHANG Hui. Research progress in poly(lactic acid)/thermoplastic polyurethane blends [J]. China Plastics, 2023, 37(9): 75-82. |

| [14] | GUAN Guotao, LIU Chenze, HE Shiquan, SONG Chaoyang, ZHANG Xiang, ZHAO Na, WANG Chao. Preparation and properties of antibacterial biodegradable poly (lactic acid) membrane [J]. China Plastics, 2023, 37(9): 8-13. |

| [15] | WANG Lei, ZHAO Min, WENG Yunxuan, ZHANG Caili. Research progress in applications and performance prediction of machine learning in PLA processing [J]. China Plastics, 2023, 37(8): 127-134. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||