京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (12): 8-18.DOI: 10.19491/j.issn.1001-9278.2024.12.002

• Materials and Properties • Previous Articles Next Articles

WEI Ce1( ), CHEN Tianyu1, ZHANG Xiutao1, ZHANG Yiyao1, ZHANG Sibo1, ZHANG Xiaoyu1, HUANG Jing1,2(

), CHEN Tianyu1, ZHANG Xiutao1, ZHANG Yiyao1, ZHANG Sibo1, ZHANG Xiaoyu1, HUANG Jing1,2( ), DONG Weifu1

), DONG Weifu1

Received:2024-07-01

Online:2024-12-26

Published:2024-12-25

CLC Number:

WEI Ce, CHEN Tianyu, ZHANG Xiutao, ZHANG Yiyao, ZHANG Sibo, ZHANG Xiaoyu, HUANG Jing, DONG Weifu. Applications and future prospects dynamic covalent cross⁃linking networks in thermoplastic polymers, A review[J]. China Plastics, 2024, 38(12): 8-18.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2024.12.002

| 样品编号 | Tg/℃ | Tc/℃ | ΔHc/J·g-1 | Tm/℃ | ΔHm/J·g-1 | σ/MPa | ε/% | E/MPa | Gf/% |

|---|---|---|---|---|---|---|---|---|---|

| PET | 80.5 | 205.6 | 38.6 | 252.2 | 39.5 | 56.0±0.8 | 618±47 | 891.00±38.62 | 0 |

| PET⁃0.1 | 81.5 | 197.4 | 38.1 | 251.3 | 38.9 | 54.3±1.4 | 753±96 | 809.52±81.09 | 0 |

| PET⁃0.3 | 81.8 | 183.7 | 36.0 | 249.4 | 37.2 | 56.3±1.0 | 703±65 | 868.31±51.08 | 0 |

| PET⁃0.5 | 82.1 | 184.9 | 31.8 | 248.8 | 33.2 | 62.3±1.1 | 338±40 | 1095.41±29.02 | 2.52 |

| PET⁃0.7 | 82.7 | 185.8 | 34.9 | 248.5 | 35.9 | 64.5±2.6 | 6±1 | 1240.94±110.42 | 66.18 |

| PET⁃1.0 | 83.0 | 185.2 | 36.0 | 248.0 | 37.5 | 63.4±2.5 | 6±1 | 1241.22±58.41 | 68.91 |

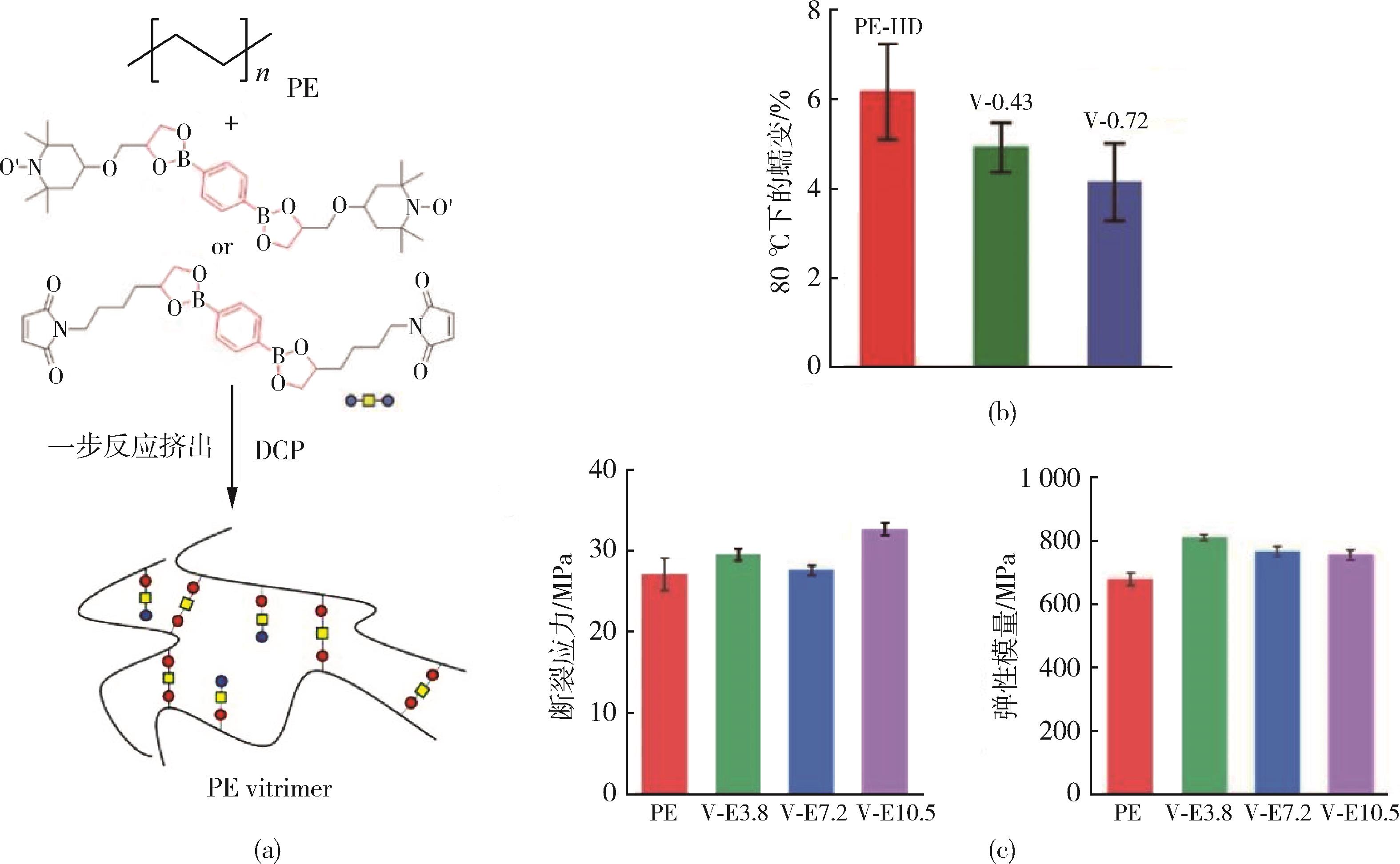

| PET⁃1.2 | 83.3 | 179.4 | 33.7 | 247.0 | 34.0 | 59.9±1.2 | 5±1 | 1262.24±135.88 | 76.29 |

| PET⁃1.5 | 84.4 | 178.4 | 32.2 | 245.1 | 33.0 | 50.9±2.3 | 4±1 | 1239.73±162.03 | 71.35 |

| PET⁃2.0 | 85.3 | 175.6 | 29.6 | 244.9 | 30.5 | 43.6±7.0 | 2±1 | 1273.22±396.00 | 69.54 |

| 样品编号 | Tg/℃ | Tc/℃ | ΔHc/J·g-1 | Tm/℃ | ΔHm/J·g-1 | σ/MPa | ε/% | E/MPa | Gf/% |

|---|---|---|---|---|---|---|---|---|---|

| PET | 80.5 | 205.6 | 38.6 | 252.2 | 39.5 | 56.0±0.8 | 618±47 | 891.00±38.62 | 0 |

| PET⁃0.1 | 81.5 | 197.4 | 38.1 | 251.3 | 38.9 | 54.3±1.4 | 753±96 | 809.52±81.09 | 0 |

| PET⁃0.3 | 81.8 | 183.7 | 36.0 | 249.4 | 37.2 | 56.3±1.0 | 703±65 | 868.31±51.08 | 0 |

| PET⁃0.5 | 82.1 | 184.9 | 31.8 | 248.8 | 33.2 | 62.3±1.1 | 338±40 | 1095.41±29.02 | 2.52 |

| PET⁃0.7 | 82.7 | 185.8 | 34.9 | 248.5 | 35.9 | 64.5±2.6 | 6±1 | 1240.94±110.42 | 66.18 |

| PET⁃1.0 | 83.0 | 185.2 | 36.0 | 248.0 | 37.5 | 63.4±2.5 | 6±1 | 1241.22±58.41 | 68.91 |

| PET⁃1.2 | 83.3 | 179.4 | 33.7 | 247.0 | 34.0 | 59.9±1.2 | 5±1 | 1262.24±135.88 | 76.29 |

| PET⁃1.5 | 84.4 | 178.4 | 32.2 | 245.1 | 33.0 | 50.9±2.3 | 4±1 | 1239.73±162.03 | 71.35 |

| PET⁃2.0 | 85.3 | 175.6 | 29.6 | 244.9 | 30.5 | 43.6±7.0 | 2±1 | 1273.22±396.00 | 69.54 |

| 1 | Zheng N, Xu Y, Zhao Q, et al. Dynamic covalent polymer networks: A molecular platform for designing functions beyond chemical recycling and self⁃healing[J]. Chemical Reviews, 2021, 121 (3): 1 716⁃1 745. |

| 2 | Guerre M, Taplan C, Winne J M, et al. Vitrimers: Directing chemical reactivity to control material properties[J]. Chemical Science, 2020, 11 (19): 4 855⁃4 870. |

| 3 | Kloxin C J, Scott T F, Adzima B J, et al. Covalent adaptable networks (CANs): A unique paradigm in crosslinked polymers[J]. Macromolecules, 2010, 43 (6): 2 643⁃2 653. |

| 4 | Denissen W, Winne J M, Du Prez F E. Vitrimers: Permanent organic networks with glass⁃like fluidity[J]. Chemical Science, 2016, 7 (1): 30⁃38. |

| 5 | Ji F, Zhou Y M, Yang Y M. Tailoring the structure and properties of epoxy⁃polyurea vitrimers via controllable network reconfiguration [J]. Journal of Materials Chemistry A, 2021, 9 (11): 7 172⁃7 179. |

| 6 | Fortman D J, Brutman J P, De Hoe G X, et al. Approaches to sustainable and continually recyclable cross⁃linked polymers[J]. ACS Sustainable Chemistry & Engineering, 2018, 6 (9): 11 145⁃11 159. |

| 7 | Montarnal D, Capelot M, Tournilhac F, et al. Silica⁃like malleable materials from permanent organic networks[J]. Science, 2011, 334 (6058): 965⁃968. |

| 8 | Zhang X. Reconfigurable, easy repairable and low⁃temperature resistant dynamic 3D polymer structures[J]. Acta Polymerica Sinica, 2016 (6): 685⁃687. |

| 9 | Zheng N, Xu Y, Zhao Q,et al. Dynamic covalent polymer networks: A molecular platform for designing functions beyond chemical recycling and self⁃healing[J]. Chemical Reviews, 2021, 121 (3): 1 716⁃1 745. |

| 10 | Zhang Z P, Rong M Z, Zhang M Q. Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities[J]. Progress in Polymer Science, 2018, 80: 39⁃93. |

| 11 | Zheng J, Png Z M, Ng S H, et al. Vitrimers: Current research trends and their emerging applications[J]. Materials Today, 2021, 51: 586⁃625. |

| 12 | Zhu G Q, Zhang J S, Huang J, et al. High⁃performance 3D printing uv⁃curable resins derived from soybean oil and gallic acid[J]. Green Chemistry, 2021, 23 (16): 5 911⁃5 923. |

| 13 | Zhang Y J, Lin Z C, Li X P, et al. One⁃step and scalable synthesis of eaa⁃based reprocessable vitrimer with superior mechanical properties[J]. Journal of Polymers and the Environment, 2024, 32 (3): 1 080⁃1 089. |

| 14 | Kloxin C J, Bowman C N. Covalent adaptable networks: Smart, reconfigurable and responsive network systems[J]. Chemical Society Reviews, 2013, 42 (17): 7 161⁃7 173. |

| 15 | Elling B R, Dichtel W R. Reprocessable cross⁃linked polymer networks: Are associative exchange mechanisms desirable[J]. ACS Central Science, 2020, 6 (9): 1 488⁃1 496. |

| 16 | Chakma P, Morley C N, Sparks J L, et al. Exploring how vitrimer⁃like properties can be achieved from dissociative exchange in anilinium salts[J]. Macromolecules, 2020, 53 (4): 1 233⁃1 244. |

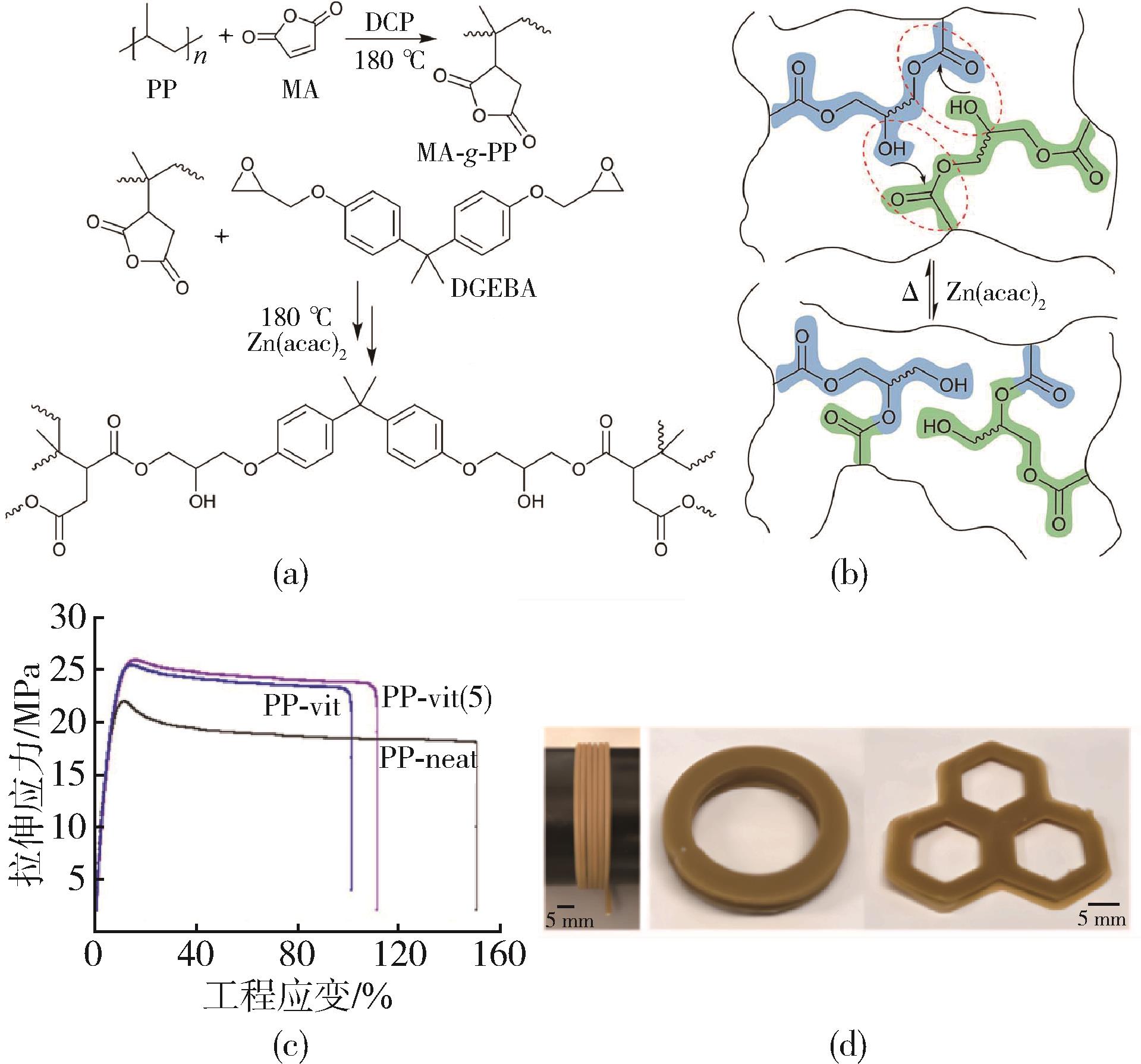

| 17 | Denissen W, Rivero G, Nicolaÿ R, et al. Vinylogous urethane vitrimers[J]. Advanced Functional Materials, 2015, 25 (16): 2 451⁃2 457. |

| 18 | 李涛. 聚乙烯化工材料的结构特点以及应用发展研究[J]. 建材与装饰, 2019 (14): 62⁃63. |

| LI T. Study on Structural Characteristics and Application Development of Polyethylene Chemical Materials [J]. Building Materials and Decoration, 2019 (14): 62⁃63. | |

| 19 | 秦丽婷. 聚乙烯的结构特点以及应用发展探析[J]. 化工设计通讯, 2022, 48 (10): 52⁃54. |

| QIN L T. Structural Characteristics and Application Development of Polyethylene [J]. Chemical Engineering Design Communications, 2022, 48 (10): 52⁃54. | |

| 20 | Kanerva M, Puolakka A, Takala T M, et al. Antibacterial polymer fibres by rosin compounding and melt⁃spinning[J]. Materials Today Communications, 2019, 20: 100 527⁃100 536. |

| 21 | Weingart N, Raps D, Lu M F, et al. Comparison of the foamability of linear and long⁃chain branched polypropylene⁃the legend of strain⁃hardening as a requirement for good foamability[J]. Polymers, 2020, 12 (3): 725⁃746. |

| 22 | Wang S, Ma S, Qiu J, et al. Upcycling of post⁃consumer polyolefin plastics to covalent adaptable networks via in situ continuous extrusion cross⁃linking[J]. Green Chemistry, 2021, 23 (8): 2 931⁃2 937. |

| 23 | Röttger M, Domenech T, van der Weegen R, et al. High⁃performance vitrimers from commodity thermoplastics through dioxaborolane metathesis[J]. Science, 2017, 356 (6333): 62⁃65. |

| 24 | Caffy F, Nicolaÿ R. Transformation of polyethylene into a vitrimer by nitroxide radical coupling of a bis⁃dioxaborolane[J]. Polymer Chemistry, 2019, 10 (23): 3 107⁃3 115. |

| 25 | Maaz M, Riba⁃Bremerch A, Guibert C, et al. Synthesis of polyethylene vitrimers in a single step: Consequences of graft structure, reactive extrusion conditions, and processing aids[J]. Macromolecules, 2021, 54 (5): 2 213⁃2 225. |

| 26 | Montoya⁃Ospina M C, Verhoogt H, Osswald T A. Processing and rheological behavior of cross⁃linked polyethylene containing disulfide bonds[J]. SPE Polymers, 2021, 3 (1): 25⁃40. |

| 27 | Zych A, Pinalli R, Soliman M, et al. Polyethylene vitrimers via silyl ether exchange reaction[J]. Polymer, 2020, 199: 122 567⁃122 573. |

| 28 | Wang S, Ma S Q, Qiu J F, et al. Upcycling of post⁃consumer polyolefin plastics to covalent adaptable networks via in sit continuous extrusion cross⁃linking[J]. Green Chemistry, 2021, 23 (8): 2 931⁃2 937. |

| 29 | Wang Z, Gu Y, Ma M, et al. Strengthening polyethylene thermoplastics through a dynamic covalent networking additive based on alkylboron chemistry[J]. Macromolecules, 2021, 54 (4): 1 760⁃1 766. |

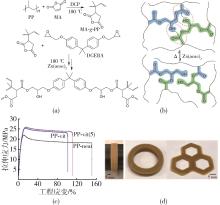

| 30 | Saed M O, Lin X, Terentjev E M. Dynamic semicrystalline networks of polypropylene with thiol⁃anhydride exchangeable crosslinks[J]. ACS Applied Materials & Interfaces, 2021, 13(35): 42 044⁃42 051. |

| 31 | Kar G P, Saed M O, Terentjev E M. Scalable upcycling of thermoplastic polyolefins into vitrimers through transesterification[J]. Journal of Materials Chemistry A, 2020, 8 (45): 24 137⁃24 147. |

| 32 | Kar G P, Lin X Y, Terentjev E M. Fused filament fabrication of a dynamically crosslinked network derived from commodity thermoplastics[J]. ACS Applied Polymer Materials, 2022, 4 (6): 4 364⁃4 372. |

| 33 | Gao Y C, Niu H. Polypropylene⁃based transesterification covalent adaptable networks with internal catalysis[J]. Polymer Chemistry, 2024, 15 (9): 884⁃895. |

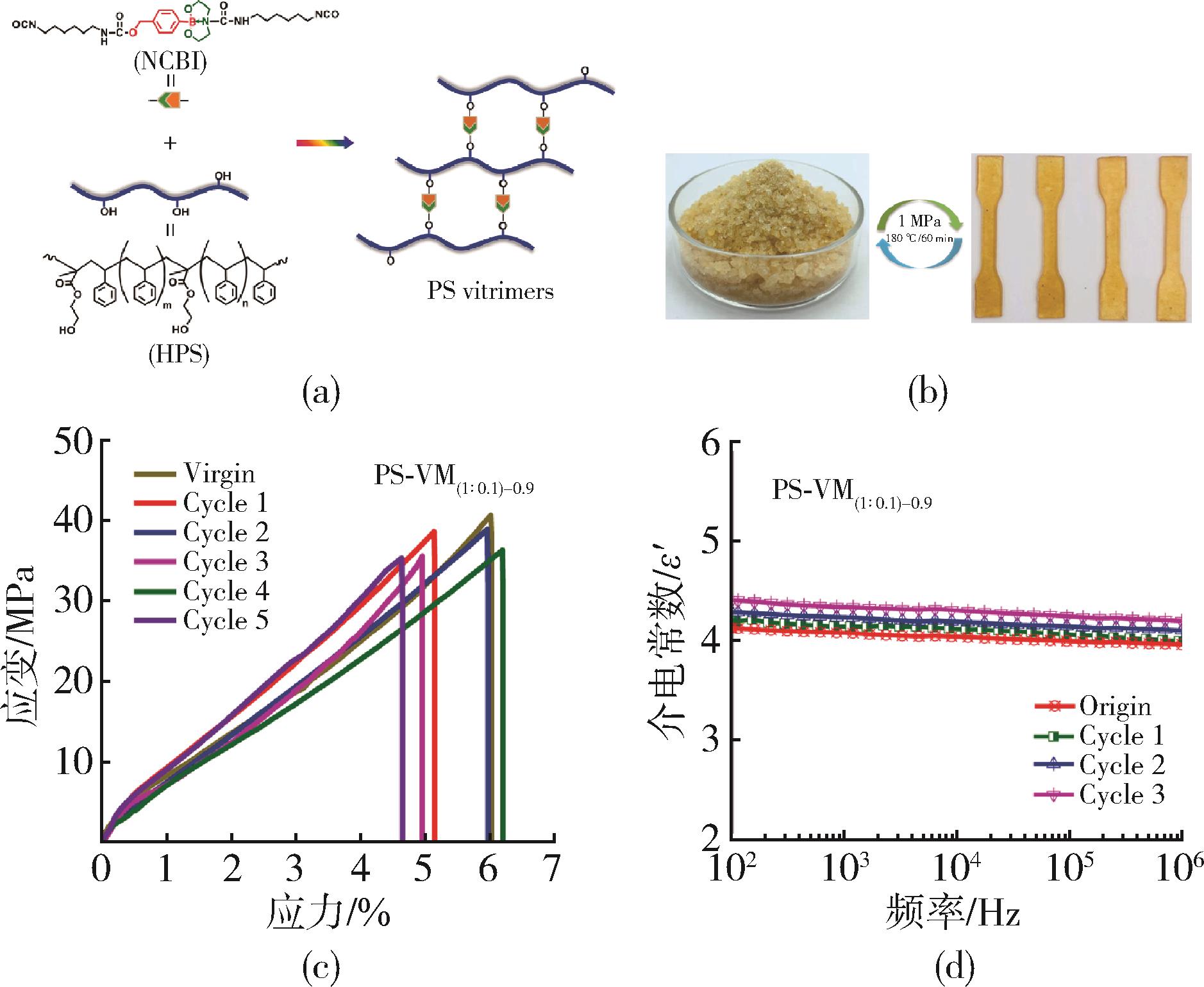

| 34 | Wang S, Wang B, Zhang X, et al. Fully recyclable and reprocessable polystyrene⁃based vitrimers with improved thermal stability and mechanical properties through nitrogen⁃coordinating cyclic boronic ester bonds[J]. Applied Surface Science, 2021, 570: 151 157⁃151 167. |

| 35 | Gad M M, Rahoma A, Al⁃Thobity A M, et al. Influence of incorporation of ZrO2 nanoparticles on the repair strength of polymethyl methacrylate denture bases[J]. International Journal of Nanomedicine, 2016, 11: 5 633⁃5 643. |

| 36 | Leao R D, Maior J R S, Lemos C A D, et al. Complications with PMMA compared with other materials used in cranioplasty: A systematic review and meta⁃analysis[J]. Brazilian Oral Research, 2018, 32 (e31): 1⁃12. |

| 37 | Leao R S, Moraes S L D, Gomes J M L, et al. Influence of addition of zirconia on pmma: A systematic review[J]. Journal of Materials Science and Engineering C, 2020, 106: 110 292⁃110 230. |

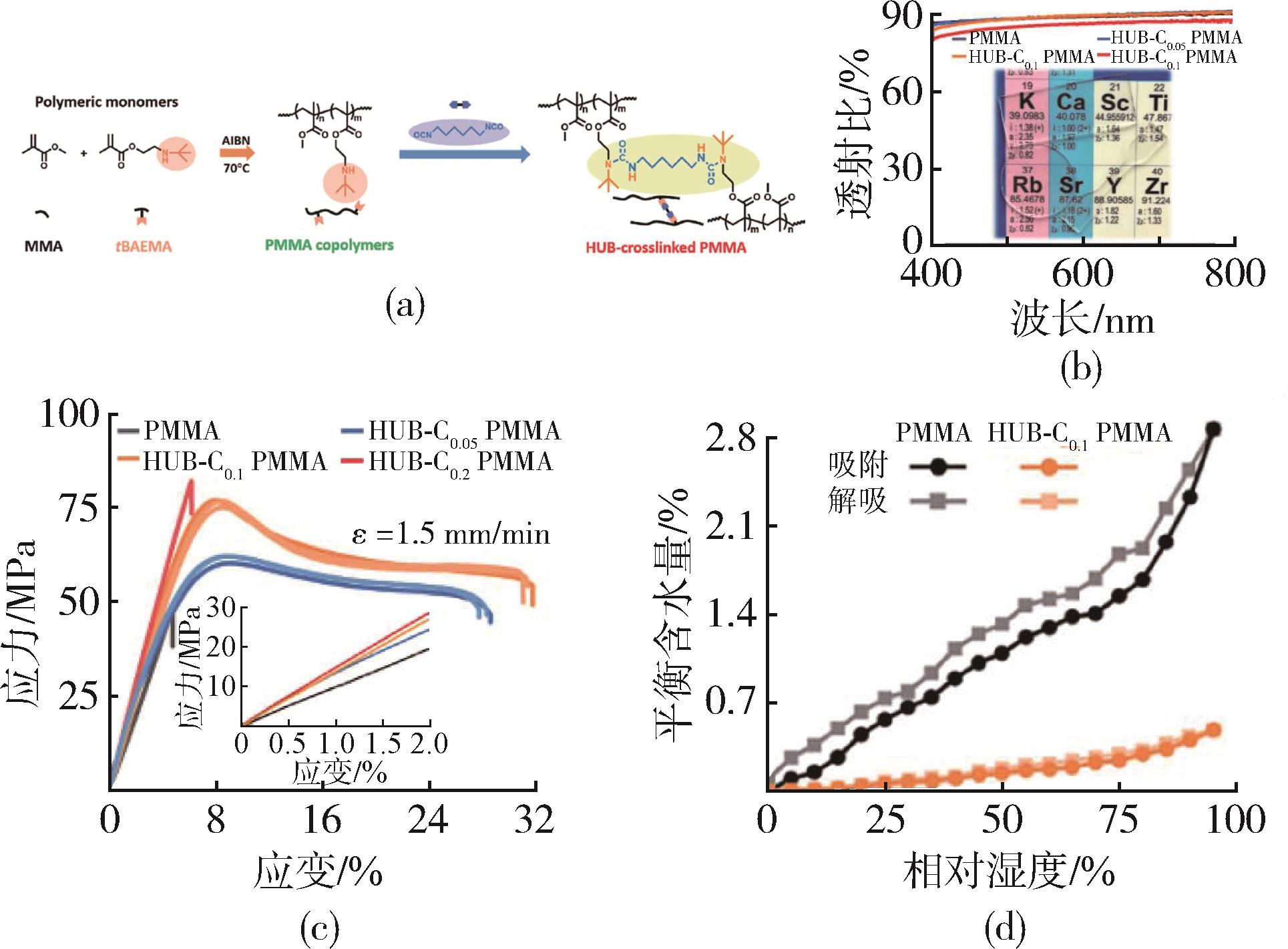

| 38 | Xie S, Wang D, Zhang S, et al. High performance poly(methyl methacrylate) via hindered urea bond crosslinking[J]. Journal of Materials Chemistry A, 2022, 10 (17): 9 457⁃9 467. |

| 39 | Lessard J J, Garcia L F, Easterling C P, et al. Catalyst⁃free vitrimers from vinyl polymers[J]. Macromolecules, 2019, 52 (5): 2 105⁃2 111. |

| 40 | Pan P, Liang Z, Zhu B, et al. Blending effects on polymorphic crystallization of poly(l⁃lactide)[J]. Macromolecules, 2009, 42: 3 374⁃3 380. |

| 41 | Rieckmann T, Völker S. Poly(ethylene terephthalate) polymerization⁃mechanism, catalysis, kinetics, mass transfer and reactor design[M]. John Wiley & Sons, Ltd, 2004: 29⁃115. |

| 42 | Zhang W, Zhang H D, Yang Y L, et al. Network homogeneity on linear and nonlinear viscoelasticity of polyethylene terephthalate vitrimers[J]. Polymer, 2024, 300: 127 015⁃127 025. |

| 43 | Qiu J F, Ma S Q, Wang S, et al. Upcycling of polyethylene terephthalate to continuously reprocessable vitrimers through reactive extrusion[J]. Macromolecules, 2021, 54(2): 703⁃712. |

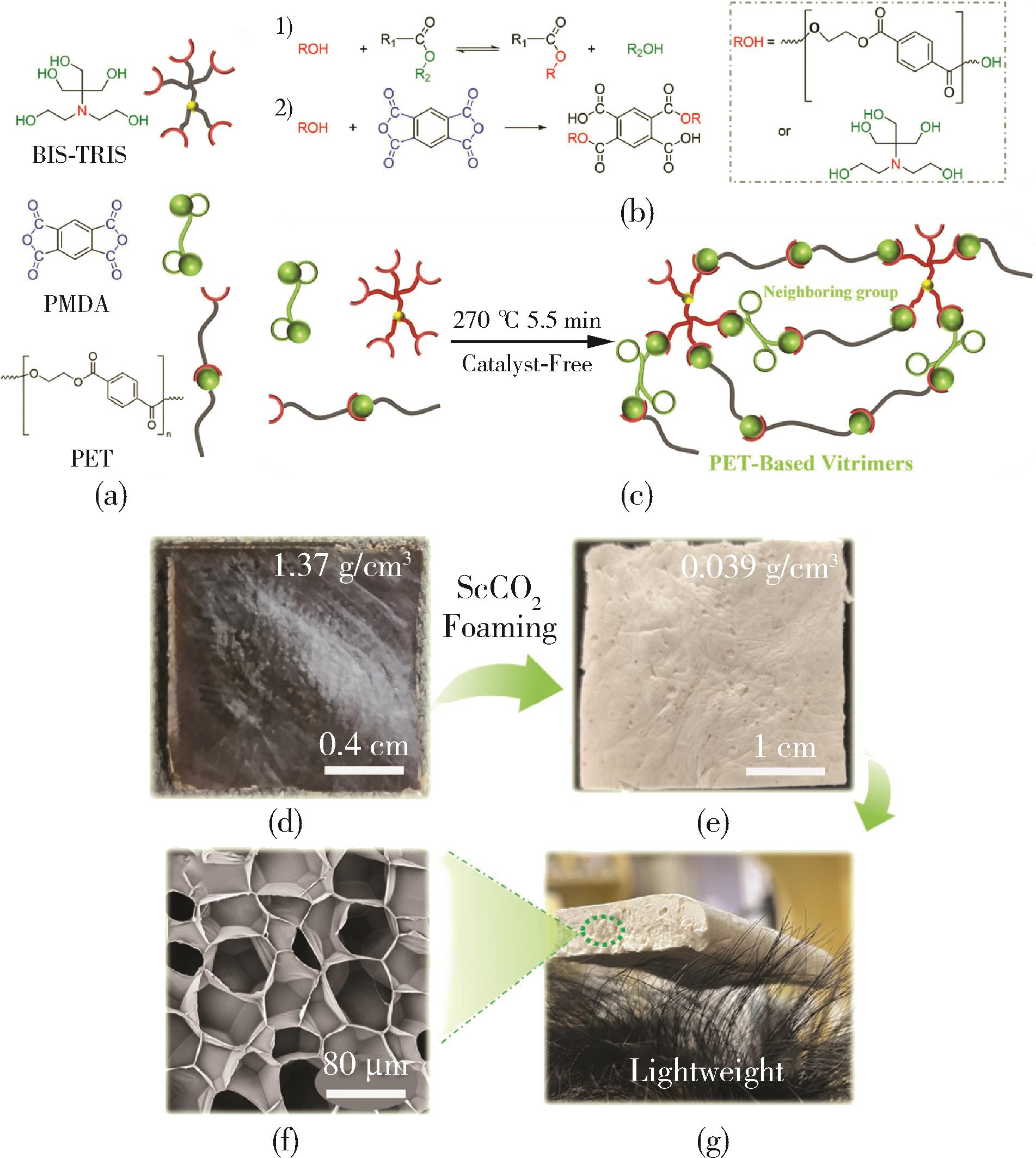

| 44 | Wu S S, Li Y D, Hu Z, et al. Fast upcycling of poly(ethylene terephthalate) into catalyst⁃free vitrimers[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(5): 1 974⁃1 984. |

| 45 | Li P, Lan B, Zhang X, et al. Facile in situ construction of a covalent adaptable network polyester vitrimer with advanced performance in repairability, foamability and recyclability[J]. Green Chemistry, 2022, 24(14): 5 490⁃5 501. |

| 46 | Vyavahare S A, Kharat B M, More A P. Polybutylene terephthalate (PBT) blends and composites: A review[J]. Vietnam Journal of Chemistry, 2024, 1⁃11. |

| 47 | Zhou Y, Goossens J G P, Sijbesma R P, et al. Poly(butylene terephthalate)/glycerol⁃based vitrimers via solid⁃state polymerization[J]. Macromolecules, 2017, 50 (17): 6 742⁃6 751. |

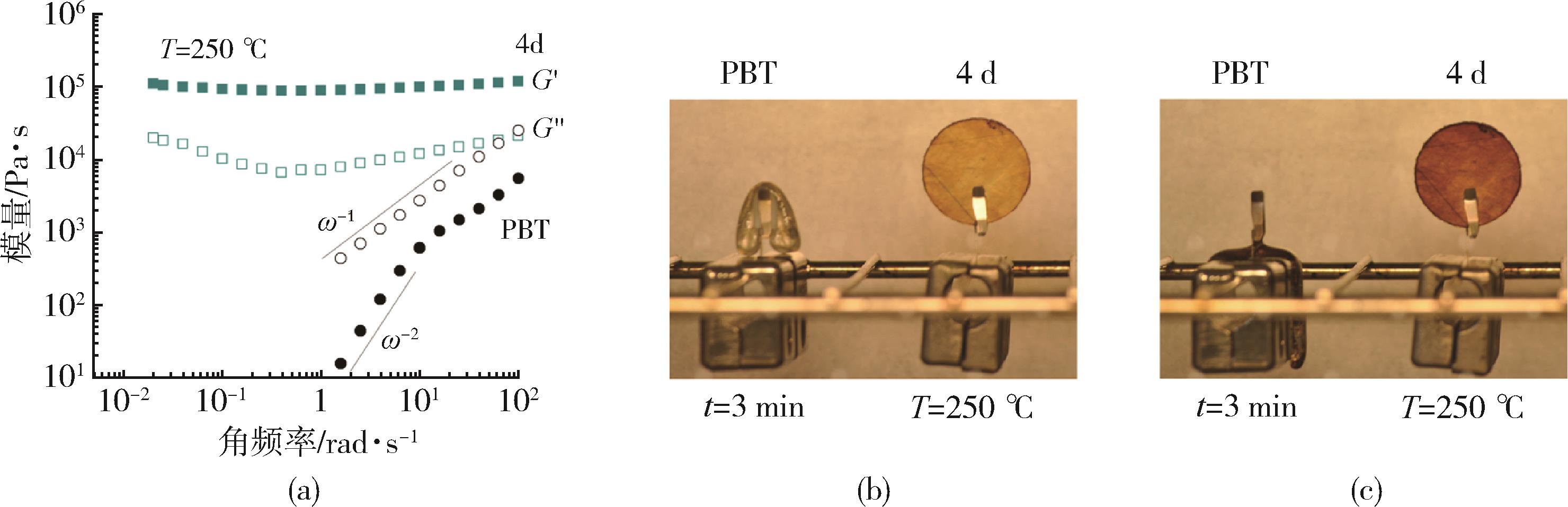

| 48 | Demongeot A, Groote R, Goossens H, et al. Cross⁃linking of poly(butylene terephthalate) by reactive extrusion using Zn(II) epoxy⁃vitrimer chemistry[J]. Macromolecules, 2017, 50 (16): 6 117⁃6 127. |

| 49 | Brutman J P, Delgado P A, Hillmyer M A. Polylactide vitrimers[J]. ACS Macro Letters, 2014, 3 (7): 607⁃610. |

| 50 | Borska K, Bednarek M, Pawlak A. Reprocessable polylactide⁃based networks containing urethane and disulfide linkages[J]. European Polymer Journal, 2021, 156: 110 636⁃110 645. |

| 51 | Liu Y B, Peng L M, Bao R Y, et al. Vitrimeric polylactide by two⁃step alcoholysis and transesterification during reactive processing for enhanced melt strength[J]. ACS Applied Materials & Interfaces, 2022, 14(40): 45 966⁃45 977. |

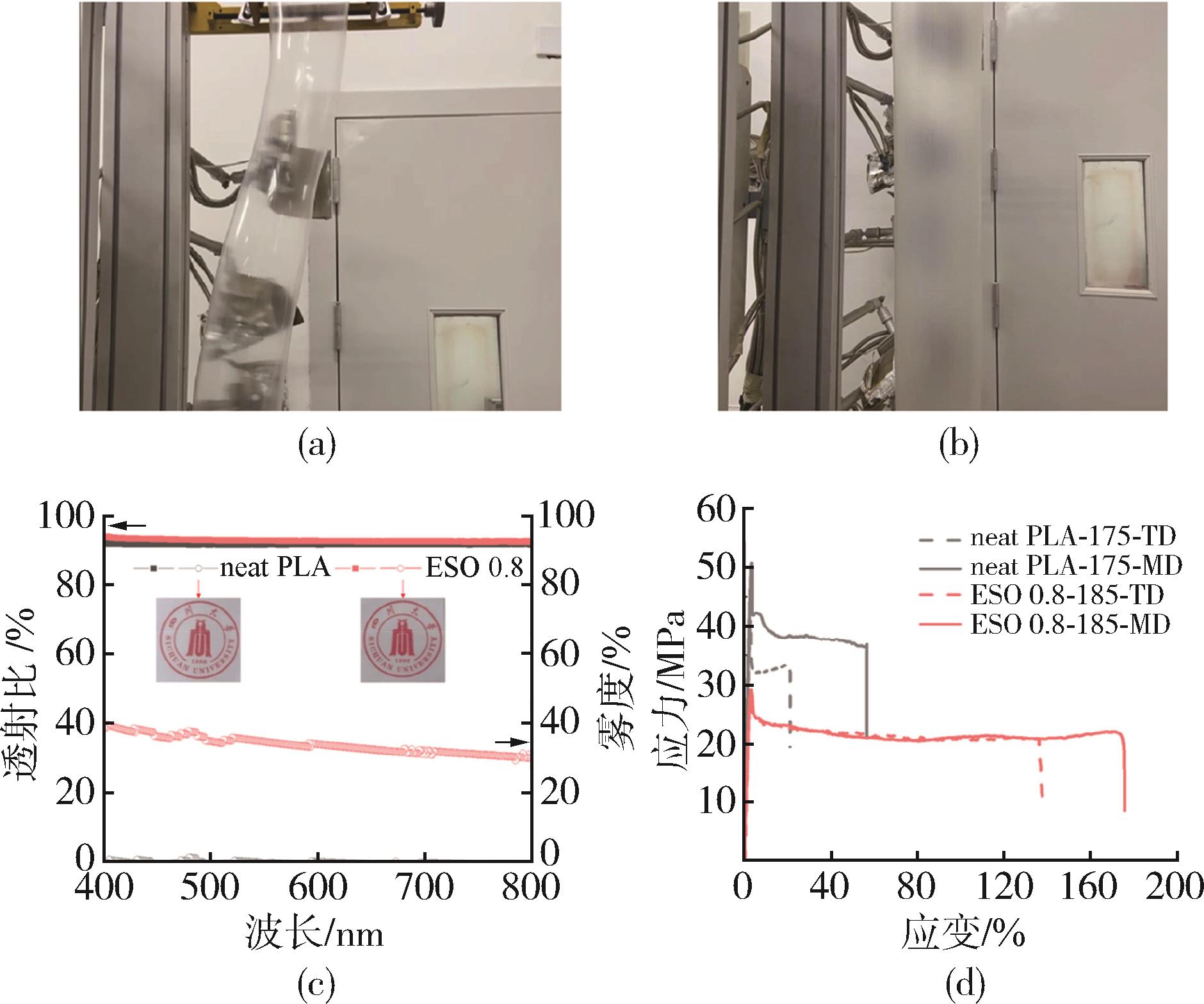

| 52 | Liu Y B, Xu Z, Zhang Z M, et al. Blowing tough polylactide film enabled by the in situ construction of covalent adaptive networks with epoxidized soybean oil as dynamic crosslinks[J]. Green Chemistry, 2023, 25(13): 5 182⁃5 194. |

| 53 | Zhou X W, Huang J, Zhang X H, et al. Design of tough, yet strong, heat⁃resistant pla/pbat blends with reconfigurable shape memory behavior by engineering exchangeable covalent crosslinks[J]. Chinese Journal of Polymer Science, 2023, 41(12): 1 868⁃1 878. |

| 54 | Xie J, Gu K, Zhao Y, et al. Enhancement of the mechanical properties of poly(lactic acid)/epoxidized soybean oil blends by the addition of 3⁃aminophenylboronic acid[J]. ACS Omega, 2022, 7( 21): 17 841⁃17 848. |

| 55 | Fourati Y, Tarrés Q, Mutjé P, Boufi S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties[J]. Carbohydrate Polymers, 2018, 199: 51⁃57. |

| 56 | Gigante V, Canesi I, Cinelli P, et al. Rubber toughening of polylactic acid (PLA) with poly(butylene adipate⁃co⁃terephthalate) (PBAT): Mechanical properties, fracture mechanics and analysis of ductile⁃to⁃brittle behavior while varying temperature and test speed[J]. European Polymer Journal, 2019, 115: 125⁃137. |

| 57 | Mofokeng T G, Ojijo V, Ray S S. The influence of blend ratio on the morphology, mechanical, thermal, and rheological properties of PP/LDPE blends[J]. Macromolecular Materials and Engineering, 2016, 301(10): 1 191⁃1 201. |

| 58 | Oromiehie A R, Lari T T, Rabiee A. Physical and thermal mechanical properties of corn starch/ldpe composites[J]. Journal of Applied Polymer Science, 2013, 127(2): 1 128⁃1 134. |

| 59 | Zheng J, Lu J, Yang Z, et al. Fabrication of recyclable and biodegradable pbat vitrimer via construction of highly dynamic cross⁃linked network[J]. Polymer Degradation and Stability, 2024, 219: 110 602⁃110 614. |

| 60 | Fan Z Y, Shi Z, Ma L, et al. Dynamic cross⁃linked poly(butylene adipate⁃co⁃terephthalate) for high⁃performance green foam[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(45): 16 354⁃16 364. |

| [1] | QU Daopeng, ZHANG Tao, HUA Chenxi, SONG Xinyu, CHENG Changli, LIU Yu, WANG Zhenyu. 3D printing of epoxy⁃based composites with high strength and electromagnetic interference shielding ability [J]. China Plastics, 2024, 38(9): 24-29. |

| [2] | HU Yongxiang, XIE Jiling, LI Weiming, ZHANG Lu, TANG Xianggang, LYU Yitong, SHEN Hongwang, JU Guannan. Effect of maleic anhydride graft⁃modified ground tire rubber on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 20-24. |

| [3] | WANG Jie, XIN Dehua, LI Hui, JIANG Hongshi, ZHOU Hongfu, ZHAO Jianguo. Effect of hybrid reinforcement of nanoclay and silica on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 43-48. |

| [4] | XU Chen, LUO Bofei, LIU Tengteng, XING Jingkai. Research progress in modification of polypropylene with nucleating agent [J]. China Plastics, 2024, 38(7): 79-85. |

| [5] | LIU Ying, SUN Hao, YANG Yong, JIANG Kaiyu, YU Tongmin, MA Sai, ZHU Tieli. Effect of ultrasonic vibration on mechanical properties of injection⁃molded parts of glass⁃fiber⁃reinforced polyamide 6 [J]. China Plastics, 2024, 38(7): 9-14. |

| [6] | YANG Lian, JIANG Jing, JIA Caiyi, XIE Yuehan, WANG Xiaofeng, LI Qian. Preparation of polyamide 6 microfiber reinforced polypropylene composite and its property of chemical foam injection molding [J]. China Plastics, 2024, 38(6): 12-18. |

| [7] | ZHOU Ziyi, WANG Yangyang, SUN Tao, JIANG Wei, DONG Tungalag, YUN Xunyan. Properties and applications of poly(butylene adipate⁃co⁃terephthalate)⁃based self⁃regulating gas film [J]. China Plastics, 2024, 38(6): 31-38. |

| [8] | DONG Yapeng, ZHAO Tianjiao, WANG Meizhen, CUI Wenju, LIN Fuhua, WANG Bo. Effect of long chain fatty acid sodium/sodium arylamide fatty acid compounding nucleating agent on properties of polypropylene [J]. China Plastics, 2024, 38(6): 60-65. |

| [9] | WANG Han, LIANG Jinhua, GAO Zhenguo, JIANG Wei, ZHOU Hao. Mechanical properties and repair efficiency of self⁃repairing microencapsulated epoxy resin [J]. China Plastics, 2024, 38(5): 40-46. |

| [10] | ZHANG Zhiqi, WANG Xiangdong, LIU Haiming, CHEN Shihong. Study on toughening modification and foaming behavior of biobased polyamide 56/polyamide 66 blends by polyamide elastomer [J]. China Plastics, 2024, 38(5): 55-60. |

| [11] | BO Haiwa, ZHAO Zhongguo, WANG Chouxuan, XUE Rong. Structural design and properties of PLA/CNTs conductive composites with high conductivity and low percolation [J]. China Plastics, 2024, 38(4): 13-18. |

| [12] | ZHOU Ziyu, SANG Xiaoming, DI Xu, XIAO Xiaohong, HUANG Xiaoxiang, CHEN Xinggang. Effect of short⁃cut p⁃aramid fibers on mechanical properties of polyacrylonitrile resin [J]. China Plastics, 2024, 38(3): 13-17. |

| [13] | CHEN Chisheng, YANG Shuai, ZHANG Jianjun, GUO Qitai, CAI Yuan, MA Sude. Effect of titanium tailings on mechanical properties of polypropylene materials [J]. China Plastics, 2024, 38(3): 26-30. |

| [14] | GUO Jiang, XU Mengyi, LI Hui, HUANG Xiang, LIN Hao, JIANG Shengbao, CHEN Shang, CHEN Cheng. Preparation and dielectric properties of polypropylene/ZrO2 composite materials [J]. China Plastics, 2024, 38(3): 44-48. |

| [15] | ZHAO Chuantao, JIA Zhixin, LIU Lijun, LI Jiqiang, ZHANG Chenchen, RONG Di, GAO Lizhen, WANG Shaofeng. Analysis of influence factors on mechanical properties of epoxy/carbon fiber composite⁃molded products [J]. China Plastics, 2024, 38(2): 26-32. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||