京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (5): 36-42.DOI: 10.19491/j.issn.1001-9278.2025.05.006

收稿日期:2024-09-04

出版日期:2025-05-26

发布日期:2025-05-22

通讯作者:

靳玉娟(1983—),女,教授,从事生物基与降解高分子材料的改性研究,jinyujuan@th.btbu.edu.cn基金资助:

FENG Shuo, ZHOU Shuyi, JIAO Yang, HU Miao, ZHANG Ruoxuan, JIN Yujuan( )

)

Received:2024-09-04

Online:2025-05-26

Published:2025-05-22

Contact:

JIN Yujuan

E-mail:jinyujuan@th.btbu.edu.cn

摘要:

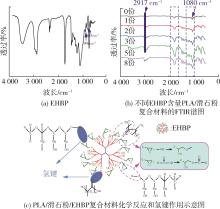

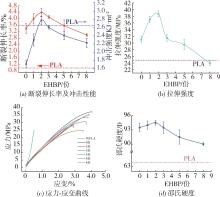

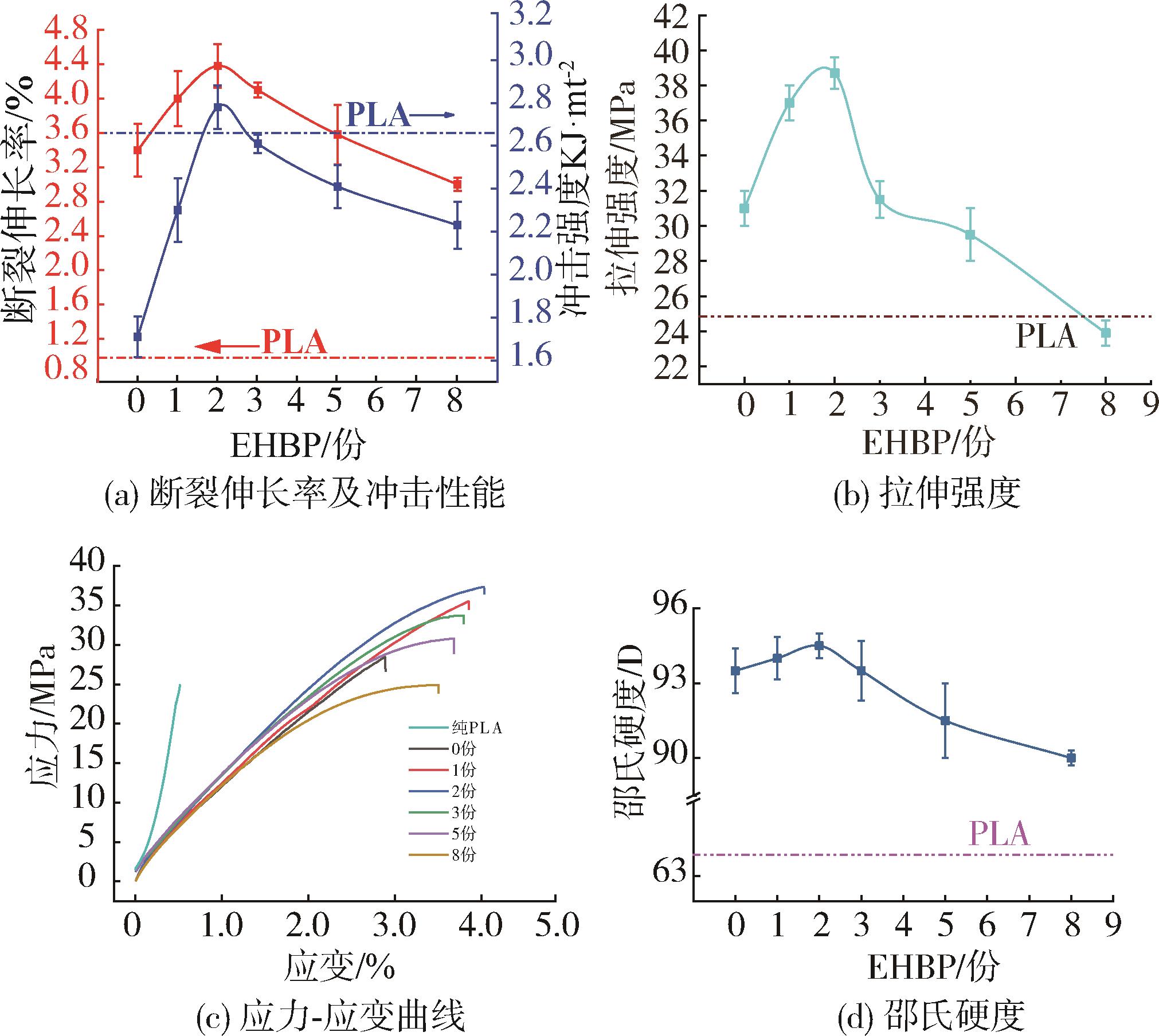

合成了端环氧基超支化聚酯(EHBP),将其与聚乳酸(PLA)/滑石粉熔融共混制得PLA/滑石粉/EHBP复合材料,并通过接触角测量仪、红外光谱仪(FTIR)、万能试验机、差示扫描量热仪(DSC)、热失重分析仪(TG)和扫描电子显微镜(SEM)等对其表面疏水性能、分子结构、力学性能、结晶性能、热性能及微观形貌等进行了表征。结果表明EHBP的加入使PLA/滑石粉复合材料结晶度降低;EHBP添加量为2份时PLA和滑石粉相容性最好;添加EHBP对PLA/滑石粉复合材料起到增强增韧作用。相对于PLA/滑石粉复合材料,当EHBP添加量为2份 时,PLA/滑石粉/EHBP复合材料的力学性能提升最大,断裂伸长率提升了29.3 %,冲击性能提升了49.8 %,拉伸强度提升了31.3 %。

中图分类号:

冯硕, 周舒毅, 焦洋, 胡淼, 张若轩, 靳玉娟. 端环氧型超支化聚酯对聚乳酸/滑石粉复合材料性能的影响研究[J]. 中国塑料, 2025, 39(5): 36-42.

FENG Shuo, ZHOU Shuyi, JIAO Yang, HU Miao, ZHANG Ruoxuan, JIN Yujuan. Effect of epoxy⁃terminated hyperbranched polyester on properties of poly(lactic acid)/talc blends[J]. China Plastics, 2025, 39(5): 36-42.

| 样品EHBP含量/份 | TC/℃ | △HC/J·g-1 | Tm1/℃ | Tm2/℃ | △Hm/J·g-1 | Xc/% | G/% |

|---|---|---|---|---|---|---|---|

| 0 | 105.61 | 21.77 | 158.32 | 165.61 | 27.43 | 29.27 | — |

| 1 | 105.01 | 22.25 | 157.95 | 165.17 | 26.65 | 27.32 | 2.84 |

| 2 | 104.80 | 22.17 | 158.14 | 165.93 | 25.09 | 25.51 | 8.53 |

| 3 | 104.02 | 21.77 | 158.06 | 165.27 | 22.77 | 25.05 | 16.99 |

| 5 | 104.27 | 21.57 | 156.86 | 164.81 | 22.10 | 24.83 | 19.43 |

| 8 | 104.68 | 21.46 | 156.12 | 164.32 | 21.35 | 24.76 | 22.17 |

| 样品EHBP含量/份 | TC/℃ | △HC/J·g-1 | Tm1/℃ | Tm2/℃ | △Hm/J·g-1 | Xc/% | G/% |

|---|---|---|---|---|---|---|---|

| 0 | 105.61 | 21.77 | 158.32 | 165.61 | 27.43 | 29.27 | — |

| 1 | 105.01 | 22.25 | 157.95 | 165.17 | 26.65 | 27.32 | 2.84 |

| 2 | 104.80 | 22.17 | 158.14 | 165.93 | 25.09 | 25.51 | 8.53 |

| 3 | 104.02 | 21.77 | 158.06 | 165.27 | 22.77 | 25.05 | 16.99 |

| 5 | 104.27 | 21.57 | 156.86 | 164.81 | 22.10 | 24.83 | 19.43 |

| 8 | 104.68 | 21.46 | 156.12 | 164.32 | 21.35 | 24.76 | 22.17 |

| 样品EHBP含量/份 | Td5/℃ | Td10/℃ | Tdmax/℃ |

|---|---|---|---|

| 0 | 310.5 | 329.3 | 360.7 |

| 1 | 310.0 | 328.8 | 361.7 |

| 2 | 309.6 | 328.3 | 362.7 |

| 3 | 309.9 | 328.6 | 359.6 |

| 5 | 309.8 | 328.7 | 356.9 |

| 8 | 307.7 | 326.4 | 351.2 |

| 样品EHBP含量/份 | Td5/℃ | Td10/℃ | Tdmax/℃ |

|---|---|---|---|

| 0 | 310.5 | 329.3 | 360.7 |

| 1 | 310.0 | 328.8 | 361.7 |

| 2 | 309.6 | 328.3 | 362.7 |

| 3 | 309.9 | 328.6 | 359.6 |

| 5 | 309.8 | 328.7 | 356.9 |

| 8 | 307.7 | 326.4 | 351.2 |

| 1 | 丁燕, 江驰, 潘剑婷, 等. 无机填料增强增韧聚乳酸基生物可降解材料的研究进展[J]. 云南化工, 2024, 51(06): 18⁃21. |

| DING Y, JIANG C, PAN J T, et al. Research progress on strengthening and toughening polylactic acid biodegradable materials by inorganic fillers [J]. Yunnan Chemical Industry, 2024, 51(06): 18⁃21. | |

| 2 | BALDOWSKA⁃WITOS P, KRUSZELNICKA W, KASNER R, et al. Application of LCA method for assessment of environmental impacts of a polylactide (PLA) bottle shaping [J]. Polymers, 2020, 12(2):388. |

| 3 | ASGHER M, QAMAR S A, BILAL M, et al. Bio⁃based active food packaging materials: Sustainable alternative to conventional petrochemical⁃based packaging materials [J]. Food Research International, 2020, 137:109625. |

| 4 | DING S, FANG C, WANG X, et al. Crystallization⁃driven microstructure changes during microphase separation for environment⁃friendly thermoplastic triblock copolymer elastomers [J]. Polymer, 2020, 186:121993. |

| 5 | 刘丰颉, 李伟, 彭新洋, et al. 聚乳酸的制备、改性及应用进展研究 [J]. 塑料科技, 2024, 52(05): 156⁃160. |

| LIU F J, LI W, PENG X Y, et al. Preparation, modification and application of polylactic acid [J]. Plastic Science and Technology, 2024, 52(05): 156⁃160. | |

| 6 | 李羽佳, 王喜明, 姚利宏, 等. 功能型植物纤维增强聚乳酸复合材料研究进展 [J]. 塑料, 2024, 53(03): 104⁃108. |

| LI Y J, WANG X M, YAO L H, et al. Research progress of functional plant fiber reinforced polylactic acid composites [J]. Plastics, 2024, 53(03): 104⁃108. | |

| 7 | 王培, 冯嘉玮, 邓祎慧,等. 聚乳酸材料性能改进研究进展 [J]. 安徽化工, 2024, 50(02): 9⁃13. |

| WANG P, FENG J W, DENG Y H, et al. Research progress on improving properties of polylactic acid materials [J]. Anhui Chemical Industry, 2024, 50(02): 9⁃13. | |

| 8 | 邓惠文. 生物降解聚乳酸增韧及其耐热改性研究[D]. 长春工业大学: 2024. |

| 9 | 江闻欣, 张广翔, 杨可, 等. 全生物降解高抗冲PLA/PBAT复合材料的制备与性能 [J]. 辽宁石油化工大学学报,2024,44(05):31⁃37. |

| JIANG W X, ZHANG G X, Yang K, et al. Preparation and properties of fully biodegradable PLA/PBAT composites with high impact resistance [J]. Journal of Liaoning Shihua University,2024,44(05):31⁃37. | |

| 10 | 刘美意, 张镇鹏, 马凤国. 硅橡胶⁃聚丙烯酸酯微球增韧聚乳酸研究 [J]. 合成材料老化与应用, 2024, 53(03): 11⁃13. |

| LIU M Y, ZHANG Z P, MA F G. Study on toughening polylactic acid with silicone rubber⁃polyacrylate microspheres [J]. Aging and Application of Synthetic Materials, 2024, 53(03): 11⁃13. | |

| 11 | 黄晓兰, 李彩玲, 刘幸琪,等. 绿色可降解生物高分子聚乳酸改性及应用研究进展 [J]. 工程塑料应用, 2021, 49(07): 162⁃166. |

| HUANG X L, LI C L, LIU X Q, et al. Research progress on modification and application of green biodegradable polylactic acid [J]. Engineering Plastics Application, 2021, 49(07): 162⁃166. | |

| 12 | 胡晨曦, 王宇韬, 祝桂香, 等. 无机填料在生物可降解塑料改性的应用进展 [J]. 塑料科技, 2022, 50(08): 83⁃87. |

| HU C X, WANG Y T, ZHU G X, et al. Progress in the application of inorganic fillers to the modification of biodegradable plastics [J]. Plastic Science and Technology, 2022, 50(08): 83⁃87. | |

| 13 | MAK S L, WU M Y T, TANG W F, et al. A review on mechanical properties modification of polymer with talc powder[C]//Proceedings of the IEEE international symposium on product compliance engineering ⁃ Asia (IEEE ISPCE⁃ASIA).Taipei:2021. |

| 14 | 孙闯闯, 丁建萍, 魏志和, 等. 耐水解PLA/PBS/滑石粉复合材料的制备及性能 [J]. 现代塑料加工应用, 2024, 36(02): 33⁃36. |

| SUN C C, DING J P, WEI Z H, et al. Preparation and properties of hydrolyzable PLA/PBS/talc composites [J]. Modern plastics processing and application, 2024, 36(02): 33⁃36. | |

| 15 | 韩嘉晖,黄汉雄,黄宇霄.滑石粉和PLA⁃g⁃MAH对聚乳酸结晶性能和熔体强度的改善[J].高等学校化学学报,2018,39(09):2 089⁃2 097. |

| HAN J, HUANG H, HUANG Y. Improving crystallization behavior and meltstrength of poly(lactic acid)via·adding talc and PLA⁃g⁃MAH[J]. Chemical Journal of Chinese Universities, 2018,39(9):2 089⁃2 097. | |

| 16 | HAO Y, TIAN H, CHEN J, et al. Roles of physical filling and chemical crosslinking on the physico⁃mechanical properties of polylactic acid [J].Journal of Applied Polymer Science, 2022,139(34) :e52808. |

| 17 | XAY, QIANS, LU W, et al. Astrategy to prepare high⁃robust and ultra⁃toughpolylactic acid/polycaprolactone/talc composites with thermo⁃resistance [J].Polymer Composites,2023, 44(12):8 750⁃8 765. |

| 18 | GHARSALLAHA, LAYACHI A, LOUAER A, et al. Thermal degradation kinetics of Opuntia Ficus Indica flour and talc⁃filled poly(lactic acid) hybrid biocomposites by TGA analysis [J]. Journal of Composite Materials, 2021, 55(22):3 099⁃3 118. |

| 19 | ZHU S, SUN M, MENG X, et al. Crystallization improvement of PLA by the talc with "grafting from" method of polymerization of lactide [J]. Journal of Polymer Research, 2024, 31(1) :20. |

| 20 | HONG Y, CHEN L, SONG G, et al. Effect of in situ and mechanical properties of polylactide/talc composites [J]. Polymer Composites, 2018, 39: 1 618⁃1 625. |

| 21 | LEE C, PANG M M, KOAY S C, et al. Talc filled polylactic⁃acid biobased polymer composites: tensile, thermal and morphological properties [J]. Sn Applied Sciences, 2020, 2(3) :354. |

| 22 | PARK S BIN, LEE YJ KU K H, et al.Triallyl isocyanurate⁃assisted grafting of maleic anhydride to poly(lactic acid): Efficient compatibilizers forpoly(lactic acid)/talc composites with enhanced mechanical properties [J].Journal ofApplied Polymer Science,2022.139(2) :e51488. |

| 23 | AVERSAC, BARLETTA M, PIZZI E, et al. Wear resistance of injectionmoulded PLA⁃talc engineered bio⁃composites: Effect of material design,thermal history and shear stresses during melt processing [J].Wear, 2017, 390/391:184⁃197. |

| 24 | SUN Z. Hyperbranched polymers in modifying natural plant fibers and their applications in polymer matrix composites⁃a review [J]. J Agric Food Chem, 2019, 67(32): 8 715⁃8 724. |

| 25 | FENG L, LI R, YANG H, et al. The hyperbranched polyester reinforced unsaturated polyester resin [J]. Polymers (Basel), 2022, 14(6) :1127. |

| 26 | XU W, WANG W, HAO L, et al. Effect of generation number on properties of fluoroalkyl‐terminated hyperbranched polyurethane latexs and its films [J]. J Appl Polym Sci, 2020, 137(40) :e49215. |

| 27 | LIU M, ZHAO L B, YU L Y, et al. Structure and properties of PSf hollow fiber membranes with different molecular weight hyperbranched polyester using pentaerythritol as core [J]. Polymers (Basel), 2020, 12(2) :383. |

| 28 | 孔祥临. 超支化聚酯/氧化石墨烯增韧环氧沥青的性能研究[D].重庆交通大学,2024. |

| 29 | CHEN S, XU Z, ZHANG D. Synthesis and application of epoxy⁃ended hyperbranched polymers [J]. Chemical Engineering Journal, 2018, 343: 283⁃302. |

| 30 | LI Z, WANG Y, LU H, et al. Stable nanoscale sea⁃island structure of biobased polyamide 56/poly (butylene adipate⁃co⁃terephthalate) blends compatibilized by interfacial hyperbranched structure: Toward biobased polymer blends with ultrahigh toughness [J]. International Journal of Biological Macromolecules, 2024, 259:129310. |

| 31 | SI J, SHAO X, WEI W, et al. Epoxy⁃ended hyperbranched polymer⁃grafted graphene oxide for cold⁃mixed epoxy asphalt modification [J]. International Journal of Pavement Engineering, 2024, 25(1) :2361344. |

| 32 | GUO M, JIN Y, HAN X, et al. Biodegradable poly (butylene adipate⁃co⁃terephthalate) and thermoplastic starch sustainable blends modified by epoxy⁃terminated hyperbranched polyester with excellent mechanical properties and high transparency [J]. Starch⁃Starke, 2023, 75(3/4) :2200169. |

| 33 | GUO M, JIN Y, HAN X, et al. Simultaneously strengthening and toughening biodegradable polylactic acid/thermoplastic starch blends by compatibilizing with epoxy⁃terminated hyperbranched polyester [J]. Journal of Polymers and the Environment, 2024, 32(7): 3 025⁃3 038. |

| 34 | HAN X, HAN Y, JIN Y, et al. Tailoring compatibility and toughness of microbial poly (3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate)/bio⁃based polyester elastomer blends by epoxy⁃terminated hyperbranched polyester [J]. International Journal of Biological Macromolecules, 2022, 220: 1 163⁃1 176. |

| 35 | HAN X, JIN Y, HUANG J, et al. Highly toughening modification of hyperbranched polyester with environment⁃friendly caprolactone as end group on poly (3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate) [J]. Journal of Polymers and the Environment, 2022, 30(8): 3 209⁃3 217. |

| 36 | LI S, WU Q, LV T, et al. Synthesis and characterization of hyperbranched polymer with epoxide⁃terminated group and application as modifier for epoxy/polyamide system [J]. Polymer Science Series B, 2017, 59(3): 328⁃336. |

| 37 | ZHOU S, GUO M, JIN Y, et al. Synergistic toughening and reinforcement of poly(lactic acid) with epoxy⁃terminated hyperbranched polymers [J]. Journal of Applied Polymer Science, 2024, 141(1): 54740. |

| 38 | SOSNOWSKI S. Poly(L⁃lactide) microspheres with controlled crystallinity [J]. Polymer, 2001, 42(2): 637⁃643. |

| 39 | ZHANG J, LIU C, CHENG J, et al. Simultaneous toughening and strengthening of diglycidyl ether of bisphenol⁃a using epoxy⁃ended hyperbranched polymers obtained from thiol⁃ene click reaction [J]. Polymer Engineering and Science, 2018, 58(10): 1 703⁃1 709. |

| [1] | 陈业中, 龚德君, 付学俊, 欧阳春平, 张怡, 尹衍升. 润滑剂种类对PBAT/PLA/碳酸钙复合材料力学性能与散发性能的影响[J]. 中国塑料, 2025, 39(5): 71-77. |

| [2] | 李万隆, 杨卫民, 王朔, 李长金, 张杨, 谭晶, 阎华, 李好义. CH⁃S04对熔体微分电纺聚乳酸纤维的增强改性研究[J]. 中国塑料, 2025, 39(2): 1-5. |

| [3] | 高成涛, 胥秋, 张黎, 李剑, 黄维, 陈劲松, 刘楠, 何声宝, 陈思瑶, 潘首慧. 无机纳米粒子在可生物降解复合材料中的应用进展[J]. 中国塑料, 2025, 39(1): 85-91. |

| [4] | 崔豹, 杨建军, 吴庆云, 吴明元, 张建安, 刘久逸. 聚乳酸复合材料共混改性研究及应用进展[J]. 中国塑料, 2024, 38(9): 129-136. |

| [5] | 马建心, 王国梁, 杜中杰, 王武聪, 金华, 邹威, 王洪, 张晨. 羟基官能化ACR的制备及其在PBT改性中的应用研究[J]. 中国塑料, 2024, 38(9): 14-19. |

| [6] | 丁馨怡, 顿东星, 秦骏熙, 陈钰蕾, 韩羽菲, 张玉霞, 周洪福. 成核剂ST⁃NAB3改性扩链聚乳酸的微观结构与性能研究[J]. 中国塑料, 2024, 38(9): 41-46. |

| [7] | 邹晓月, 徐佳慧, 陈振树, 杨友强, 陆湛泉, 贾雨欣, 李成, 叶南飚, 曹堃. 口罩过滤材料及其驻极技术的研究进展[J]. 中国塑料, 2024, 38(9): 47-53. |

| [8] | 董光, 侯仰喆, 袁洪跃, 刘宪虎, 潘亚敏. 多孔聚乳酸材料的制备及结构性能优化进展[J]. 中国塑料, 2024, 38(8): 132-140. |

| [9] | 胡永祥, 谢纪岭, 李伟铭, 张璐, 汤香港, 吕亿同, 申红望, 鞠冠男. 马来酸酐接枝改性GTR对聚乳酸性能的影响[J]. 中国塑料, 2024, 38(7): 20-24. |

| [10] | 王杰, 辛德华, 李晖, 蒋洪石, 周洪福, 赵建国. 纳米黏土与二氧化硅协同改性聚乳酸研究[J]. 中国塑料, 2024, 38(7): 43-48. |

| [11] | 骆佳伟, 周炳, 王洪学, 贾钦. 扩链条件对聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯/滑石粉共混物性能的影响[J]. 中国塑料, 2024, 38(6): 1-11. |

| [12] | 杨超永, 郭金强, 王富玉, 张玉霞. 挤出吹塑工艺对PBAT/PLA共混体系微观结构与性能的影响[J]. 中国塑料, 2024, 38(5): 82-87. |

| [13] | 孛海娃, 赵中国, 王筹萱, 薛嵘. 高导电、低逾渗PLA/CNTs导电复合材料的结构设计及性能研究[J]. 中国塑料, 2024, 38(4): 13-18. |

| [14] | 沈丹彤, 薛雨亭, 李荣杰, 徐芳, 翁云宣. 聚乳酸基水性聚氨酯的制备及其在合成革中的应用研究[J]. 中国塑料, 2024, 38(4): 19-25. |

| [15] | 戚士界, 游翔宇, 王瑞晨, 周琳菲, 张慧洁. 高木质素含量聚乳酸共混材料的制备及其性能研究[J]. 中国塑料, 2024, 38(2): 45-51. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2