京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (12): 143-150.DOI: 10.19491/j.issn.1001-9278.2025.12.022

• 综述 • 上一篇

收稿日期:2024-12-18

出版日期:2025-12-26

发布日期:2025-12-22

通讯作者:

师文钊(1986—),副教授,从事功能性形状记忆复合材料及高性能相变复合材料研究,shiwenzhao@xpu.edu.cn

LIU Yi, SHI Wenzhao( ), LIU Jinshu, LU Shaofeng, DONG Jiankun, CHEN Yuanpeng

), LIU Jinshu, LU Shaofeng, DONG Jiankun, CHEN Yuanpeng

Received:2024-12-18

Online:2025-12-26

Published:2025-12-22

Contact:

SHI Wenzhao

E-mail:shiwenzhao@xpu.edu.cn

摘要:

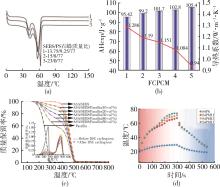

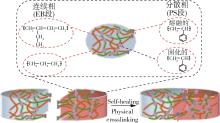

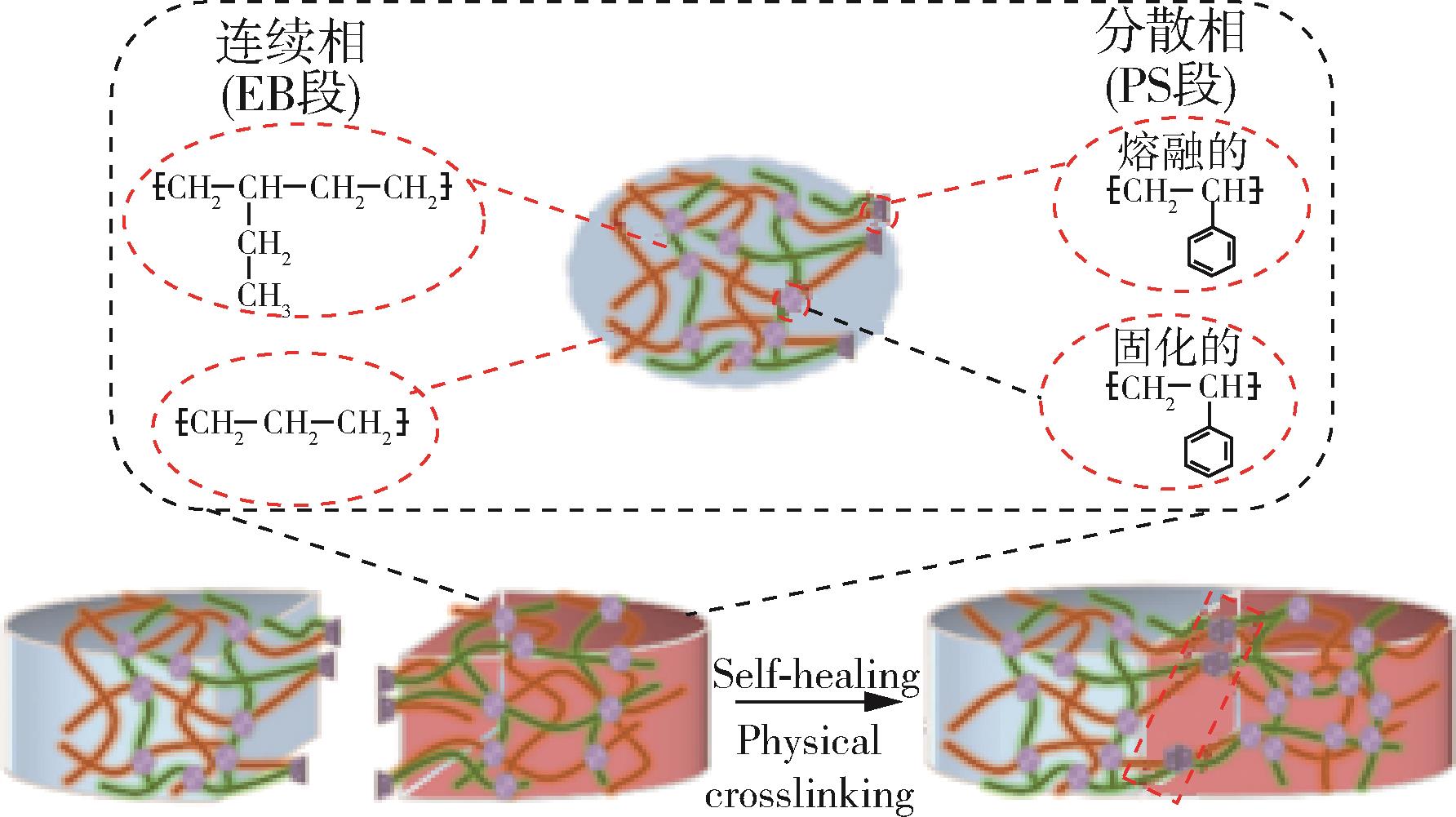

综述了热塑性弹性体丁苯⁃乙烯⁃丁二烯⁃苯乙烯嵌段共聚物(styrene⁃butadiene butadiene⁃styrene block copolymer,SEBS)基复合相变材料的结构设计及其热特性、介电性能及柔性性能等,阐述了其在电子元器件、建筑节能、人体热管理等领域的应用进展,并展望了高性能、功能化和高附加值的SEBS基复合相变材料及未来的应用领域拓展。

中图分类号:

刘怡, 师文钊, 刘瑾姝, 陆少锋, 董涧锟, 陈元鹏. SEBS基复合相变材料研究进展[J]. 中国塑料, 2025, 39(12): 143-150.

LIU Yi, SHI Wenzhao, LIU Jinshu, LU Shaofeng, DONG Jiankun, CHEN Yuanpeng. Research progress in SEBS⁃based composite phase change materials[J]. China Plastics, 2025, 39(12): 143-150.

| [1] | Chen X, Zhang H F, Li K J, et al. Enabling superior thermo⁃oxidative resistance elastomers based on a structure recovery strategy. [J] Macromolecular Rapid Communications, 2021, 42(9): 2000762. DOI: 10.1002/marc.202000762 . |

| [2] | 文敬滨,龚光碧,冯裕智,等.热塑性弹性体研究进展[J].合成树脂及塑料,2023,40(05):76⁃82+86.DOI: 10.19825/j.issn.1002-1396.2023.05.15 . |

| [3] | 马 晓.一种耐高温的热塑性弹性体材料及其制备方法[J].橡胶工业,2020,67(11):867. |

| [4] | 曾 龙,邱 建,李 萍.防结块热塑性弹性体材料的制备与性能[J].山西化工,2023,43(10):7⁃9.DOI: 10.16525/j.cnki.cn14-1109/tq.2023.10.004 . |

| [5] | Yang C, Lu J, Guan S. High frequency radar transmittance in bumper and exterior trim parts molded from thermoplastic olefins (TPOs): Part I TPO base resin. [J].Journal of Applied Polymer Science, 2023, 140(47): 54696. DOI: 10.1002/app.54696 . |

| [6] | Huang S, Wang Q, Li Z H, et al. Research on the lightweight Application of Micro⁃foaming TPV Material in Glass Guide Assembly[C]// China Society of Automotive Engineers. 2020:1. DOI:10.26914/c.cnkihy.2020.023535 . |

| [7] | Du J W, Zhou T T, Zhang R, et al. Influence of TPU/EVA phase morphology evolution on supercritical carbon dioxide extrusion foaming.[J].Polymers,2023,15(14):3134. DOI: 10.3390/polym15143134 . |

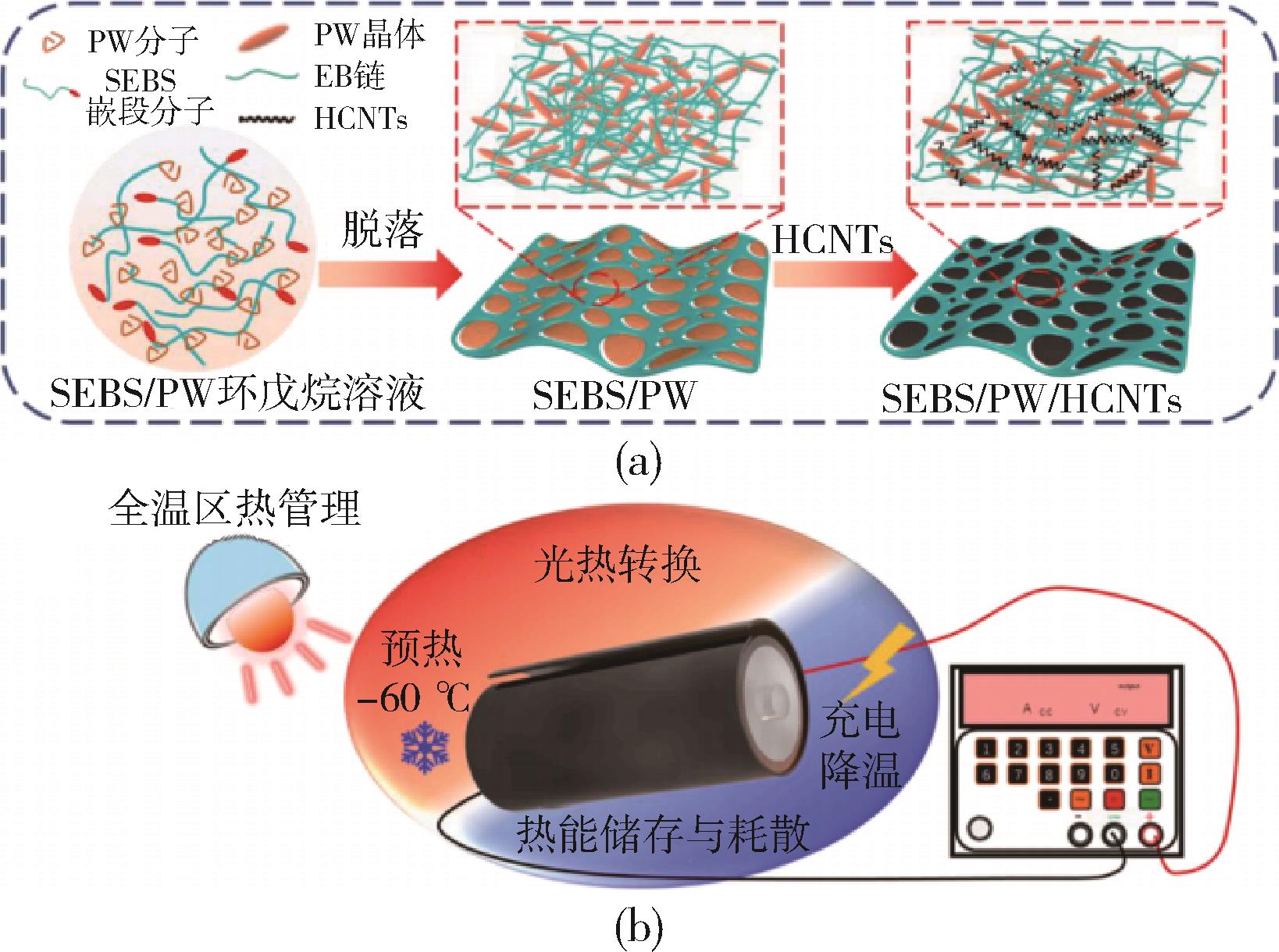

| [8] | Xu Z R, Wang G L, Wang Z Z,et al. High performance plant⁃derived thermoplastic polyester elastomer foams achieved by manipulating charging order of mixed blowing agents[J]. International Journal of Biological Macromolecules, 2023,252: 126261. DOI: 10.1016/j.ijbiomac.2023.126261 . |

| [9] | 蔡新宇,张 凯,王 露,等.纺膜参数对PVC中空纤维膜结构与性能的影响[J].膜科学与技术,2024,44(02):37⁃44.DOI:10.16159/j.cnki.issn1007-8924.2024.02.005 . |

| [10] | 万艳红.氯化聚乙烯及专用料的研究进展[J].中国塑料,2023,37(11):35⁃45. DOI: 10.19491/j.issn.1001-9278.2023.11.005 . |

| [11] | Cai K, Wang X D, Yu C H,et al. Enhancing the Mechanical Properties of PBAT/Thermoplastic Starch (TPS) Biodegradable Composite Films through a Dynamic Vulcanization Process[J]. ACS Sustainable Chemistry & Engineering, 2024, 12(4): 1573⁃1583. DOI: 10.1021/acssuschemeng.3c06847 . |

| [12] | 孙振龙,闫顺杰,周容涛,等.苯乙烯类热塑性弹性体的生物功能改性研究进展[J].青岛科技大学学报(自然科学版),2021,42(01):85⁃92.DOI:10.16351/j.1672-6987.2021.01.013 . |

| [13] | 高文通,张奕磊,陈 韶,等.无机填料种类及粒径对SEBS共混体系性能的影响[J].弹性体,2022,32(02):6⁃10+33.DOI: 10.16665/j.cnki.issn1005-3174.2022.02.016 . |

| [14] | 王玉雪,蔡保成.苯乙烯类热塑性弹性体的改性研究与应用分析[J].安徽化工,2023,49(3):12⁃15. |

| [15] | Chuang P L, Nien Y H. Synthesis and characterization of maleic anhydride grafted SEBS modified with ethanolamine, 2⁃amino-2⁃methyl-1⁃propanol or glycerine[J]. Journal of Polymer Research, 2019, 26(3): 66. |

| [16] | Purbasha M, Chaitanya K S, Mithun D, et al.Strategic fabrication of SEBS composite with high strength and stretchability via incorporation of polymer⁃grafted cellulose nanofibers for biomedical applications[J].Cellulose,2023,30(15):9 465⁃9 484. |

| [17] | Mao J, Wang T, Liang Y, et al.Organic long⁃persistent luminescence materials with stretchability enabled by SEBS[J].Chemical Engineering Journal,2024,498155612⁃155612. |

| [18] | Kyungwhan M, Eon J C, Yerim L, et al. Crosslinked poly(m⁃terphenyl N⁃methyl piperidinium)⁃SEBS membranes with aryl⁃ether free and kinked backbones as highly stable and conductive anion exchange membranes[J].Journal of Membrane Science,2022,653. |

| [19] | Shuwen L, Jun Q, Lili H, et al. Effect of SEBS Molecular Structure and Formula Composition on the Performance of SEBS/PP TPE for Automotive Interior Skin.[J].Polymers,2023,15(12):2753⁃.0.1007/s10965⁃019⁃1723⁃7. |

| [20] | Zheng C F, Wang L, Zhao D J.Experimental Study on Pavement Performance of SEBS Modified Asphalt Mixture[J].Advanced Materials Research, 2011, 168⁃170:906⁃911.DOI:10.4028/www.scientific.net/AMR.168-170.906 . |

| [21] | Azevedo V F S D, Alberto M F A D, Cristine M L A D, et al.Efficiency assessment of the SEBS, SEP, and SBS copolymers in the compatibilization of the PS/ABS blend[J].Journal of Polymer Research,2023,30(11). |

| [22] | Chuan L, Qi L, Ruihuan G.Synthesis and investigation of form⁃stable myristic acid based composite phase change material containing styrene ethylene butylene styrene with enhanced properties for thermal energy storage[J].Journal of Energy Storage,2022,52(PA). |

| [23] | Rickert R, Klein R, Schoenberger F. Form⁃Stable Phase Change Materials Based on SEBS and Paraffin: Influence of Molecular Parameters of Styrene⁃b⁃(Ethylene⁃co⁃Butylene)⁃b⁃Styrene on Shape Stability and Retention Behavior[J].Materials, 2020, 13(15): 3285. DOI:10.3390/ma13153285 . |

| [24] | Aulakh J S, Joshi D P. Thermal and morphological study of paraffin/SEBS/expanded graphite composite phase change material for thermal energy storage [J].Energy sources Part A. Recovery Utilization and Environmental Effects, 2022,44(1): 986⁃1003. DOI:10.1080/15567036.2022.2053764 . |

| [25] | 郭 宁,王铭锋,张志丽,等.具有双连续结构的BN/PP/SEBS复合材料导热与绝缘性能的研究[J].中国电机工程学报,2024,44(03):1214⁃1224.DOI:10.13334/j.0258-8013.pcsee.223341 . |

| [26] | Zhang Q L, Zhao Y Q, Feng J C, et al. Systematic investigation on shape stability of high⁃efficiency SEBS/paraffin form⁃stable phase change materials [J].Solar Energy Materials and Solar Cells, 2023, 118: 54⁃60. DOI: 10.1016/j.solmat.2013.07.035 |

| [27] | A I C, A A T, B M K,et al.Thermal properties of shape⁃stabilized phase change materials based on Low Density Polyethylene, Hexadecane and SEBS for thermal energy storage ⁃ ScienceDirect[J].Applied Thermal Engineering, 171[2024⁃11⁃26].DOI:10.1016/j.applthermaleng.2020.115072 . |

| [28] | Lu F, Liu Y, Gao S X, et al. SEBS⁃b⁃TPU and nanoclay: effective compatibilizers for promotion of the interfacial adhesion and properties of immiscible SEBS/TPU blends[J].Polymer bulletin, 2021, 78(6):3293⁃3310. DOI: 10.1007/s00289-020-03272-7 . |

| [29] | 范 宇,王言伦,杨 杰.原位聚合制备微胶囊相变材料及性能评价[J].塑料工业,2010,38(08):15⁃17+21. |

| [30] | Juárez D, Ferrand S, Fenollar O,et al.Improvement of thermal inertia of styrene–ethylene/butylene–styrene (SEBS) polymers by addition of microencapsulated phase change materials (PCMs)[J].European Polymer Journal, 2011, 47(2):153⁃161.DOI:10.1016/j.eurpolymj.2010.11.004 . |

| [31] | Zaichao L, Yuang Z, Fantao M, et al.Flexible phase change materials for low temperature thermal management in lithium⁃ion batteries[J].Journal of Energy Storage,2023,74(PA). |

| [32] | 王言伦,范 宇,张 刚,等.石蜡、SEBS和聚苯乙烯共混的复合定形相变材料的制备和热分析[J].塑料工业,2009,37(9):26⁃29. |

| [33] | Liu X Q, Wang C H, Wu T T,et al. A novel stable and flexible composite phase change materials for battery thermal management [J]. Applied Thermal Engineering, 2022, 212: 118510. DOI: 10.1016/j.applthermaleng.2022.118510 . |

| [34] | Xiang B, Yang Z B, Zhang J.ASA/SEBS/paraffin composites as phase change material for potential cooling and heating applications in building[J].Polymers for Advanced Technologies, 2021, 32(1): 420⁃427. DOI:10.1002/pat.5097 . |

| [35] | Sun Y, Zhang N, Sun Q,et al.A novel form⁃stable phase change material based on elastomeric copolymer and carbon nanotubes with photo⁃thermal conversion performance[J].Journal of Energy Storage, 2023.63:107043. DOI: 10.1016/j.est.2023.107043 . |

| [36] | He Y J, Xiao Y Y, Wang R Q, et al. Helical carbon nanotubes filled phase change composites with reversible plasticity shape memory and photo⁃thermal conversion functions towards wide⁃temperature⁃range battery thermal management[J].Composites Part A⁃Applied Science and Manufacturing, 2022,162:107139. DOI:10.1016/j.compositesa.2022.107139 . |

| [37] | 耿银良,李建立,张云芳.柔性复合相变材料用于锂离子电池热管理的效果模拟研究[J].化工新型材料,2024,52(03):187⁃192.DOI:10.19817/j.cnki.issn1006-3536.2024.03.008 . |

| [38] | Wu T T, Hu Y X, Rong H Q,et al. SEBS⁃based composite phase change material with thermal shape memory for thermal management applications [J]. Energy, 2021,221: 119900. DOI:10.1016/j.energy.2021.119900 . |

| [39] | Zhang Q, Wang Y J, Zhang X L, et al. Self⁃healing, elastic and deformable novel composite phase change polymer based on thermoplastic elastomer SEBS for wearable devices[J].Journal of Materials Science, 2022, 57(14):7208⁃7224. DOI: 10.1007/s10853-022-07097-9 . |

| [40] | Deng Q, Liu Q, Nian Y L, et al. A novel flexible composite phase change material with enhanced toughness and shape stability for battery thermal management [J]. Journal of Energy Storage, 2023, 72: 108701. DOI: 10.1016/j.est.2023.108701 . |

| [41] | Schomburg F, Heidrich B, Wennemar S.Lithium⁃ion battery cell formation: status and future directions towards a knowledge⁃based process design[J].Energy & environmental science: EES, 2024, 17(8):2 686⁃2 733. |

| [42] | 宋梦琼,彭宇,廖自强.基于电化学热耦合模型的电池热管理研究[J].储能科学与技术, 2024, 13(2): 578⁃585. DOI: 10.19799/j.cnki.2095-4239.2023.0620 . |

| [43] | 何瑞强,方敏,周健夺, 等.锂电池热管理用TPE基柔性复合相变材料的研究进展[J].化工进展,2024,43(06):3159⁃3173. DOI:10.16085/j.issn.1000-6613.2023-0855 . |

| [44] | Deng J, Li X X, Zhang G Q, et al. Flexible composite phase⁃change material with shape recovery and antileakage properties for battery thermal management[J].ACS Applied Energy Materials, 2022, 4(12): 13890⁃13902. DOI: 10.1021/acsaem.1c02694 . |

| [45] | Cao J H, Ling Z Y, Lin X M,et al. Flexible composite phase change material with enhanced thermophysical, dielectric, and mechanical properties for battery thermal management[J].Journal of Energy Storage, 2022,52:104796. DOI: 10.1016/j.est.2022.104796 . |

| [46] | Castleton H F, Stovin V, Beck S B M,et al.Green roofs; building energy savings and the potential for retrofit[J].Energy & Buildings, 2010, 42(10):1582⁃1591.DOI:10.1016/j.enbuild.2010.05.004 . |

| [47] | Royon L, Karim L, Bontemps A. Thermal energy storage and release of a new component with PCM for integration in floors for thermal management of buildings[J].Energy and Buildings,2013,63:29⁃35. DOI: 10.1016/j.enbuild.2013.03.042 . |

| [48] | Yucan P, Yi C.Thermal management with innovative fibers and textiles: manipulating heat transport, storage and conversion[J].National Science Review, 2024.DOI:10.1093/nsr/nwae295 . |

| [49] | Gu B, Dai Z, Pan H,et al.Integration of prolonged phase⁃change thermal storage material and radiative cooling textile for personal thermal management[J].Chemical Engineering Journal, 2024, 493.DOI:10.1016/j.cej.2024.152637 . |

| [50] | Jing Y G, Zhao Z C, Cao X l, et al. Ultraflexible, cost⁃effective and scalable polymer⁃based phase change composites via chemical cross⁃linking for wearable thermal management [J]. Nature Communications, 2023, 14(1): 8060. DOI: 10.1038/s41467-023-43772-4 . |

| [51] | Zhao Y J, Shen S W, Wang X Y, et al. Flexible stretchable SEBS/n⁃alkane phase change composite films for highly efficient thermal management and infrared stealth applications[J]. Energy and Buildings, 2023, 285: 112933. DOI: 10.1016/j.enbuild.2023.112933 . |

| [52] | 吴 熠,张 超,凌子夜,等.石蜡/SEBS复合相变材料热疗鼻贴的研究[J].储能科学与技术, 2021, 10(4):1 285⁃1 291. DOI: 10.19799/j.cnki.2095-4239.2021.0040 . |

| [1] | 韩雨生, 杨建军, 郑莹, 王雅骁. 3D打印柔性可拉伸离散功能梯度衬底的界面结构设计[J]. 中国塑料, 2025, 39(9): 68-74. |

| [2] | 陈元民, 赵梦宇, 仇思源, 李亚娇, 王文昊, 王昊, 朱广迎, 孙靖尧. 面向胸腹式呼吸检测需求的柔性传感器制备[J]. 中国塑料, 2025, 39(6): 36-41. |

| [3] | 张学敏, 王庆岗, 张雪茹, 李厚补, 齐国权, 丁晗, 高雄, 杨文辉. 高阻隔非金属柔性复合管承压性能模拟[J]. 中国塑料, 2023, 37(12): 70-77. |

| [4] | 俞红锂, 刘茜. 介电弹性体驱动器在柔性机器人中的研究进展[J]. 中国塑料, 2023, 37(10): 144-152. |

| [5] | 李正典, 宋乐, 李明昊, 何雪涛, 谢鹏程, 杨卫民. 注射成型柔性制造模具系统的设计与实验研究[J]. 中国塑料, 2022, 36(7): 104-108. |

| [6] | 宋银宝, 杨建军, 李传敏. PDMS/SiC功能梯度复合材料性能与制造精度研究[J]. 中国塑料, 2022, 36(7): 30-36. |

| [7] | 乔宗文, 邓嘉琪, 冀威. 用于甲醇燃料电池的聚砜阳离子交换膜的构⁃效关系[J]. 中国塑料, 2022, 36(5): 62-67. |

| [8] | 李娟, 王亚桥. 聚四氟乙烯原位纤维化对TPEE/PTFE复合材料发泡行为的影响[J]. 中国塑料, 2022, 36(12): 38-43. |

| [9] | 周丹砚, 黄汉雄. 基于导电涂层微结构TPU柔性传感器的制备和性能[J]. 中国塑料, 2022, 36(11): 1-6. |

| [10] | 宋仁达, 武高健, 陈俊祥, 朱金柏, 张有忱, 杨卫民, 谢鹏程. 电磁屏蔽材料的发展现状及未来发展趋势[J]. 中国塑料, 2021, 35(11): 138-143. |

| [11] | 许冬峰 冯新星 张卫东 潘凯. 长碳链聚酰胺1012弹性体的合成与表征[J]. 中国塑料, 2019, 33(3): 17-21,27. |

| [12] | 何小强 邹威 王洪 李超 张晨. 柔性环氧树脂的制备及其性能研究[J]. 中国塑料, 2019, 33(11): 1-5. |

| [13] | 杨扬 张永海 白宝丰 陈静波 申长雨. 分形维数测定方法对测量结果的影响分析 [J]. 中国塑料, 2013, 27(07): 68-72. |

| [14] | 沈韦韦 怀乐 张云灿. 亚临界水挤出法复合诱导丁苯橡胶基轮胎胶脱硫化及其对热塑性弹性体性能的影响[J]. 中国塑料, 2013, 27(05): 87-94 . |

| [15] | 吴长城, 刘喜, . EPT接枝共聚物的制备及其对PA6/EPT共混体系的增容作用 [J]. 中国塑料, 2013, 27(01): 42-47. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2