京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (9): 74-84.DOI: 10.19491/j.issn.1001-9278.2022.09.012

收稿日期:2022-05-27

出版日期:2022-09-26

发布日期:2022-09-26

通讯作者:

林祥(1983—),男,博士/副教授,从事全生物降解功能高分子材料的制备与加工研究工作,linxiang@ustb.edu.cn

MA Chao1, MA Lanrong2, WEI Liao2, YIN Huibo2, LIN Xiang1( )

)

Received:2022-05-27

Online:2022-09-26

Published:2022-09-26

Contact:

LIN Xiang

E-mail:linxiang@ustb.edu.cn

摘要:

从具有广阔应用前景的聚乙醇酸(PGA)材料的物性、加工改性及应用等方面概括了PGA的基本改性原理、改性方法以及加工过程中需要注意的问题;从增韧、增强、增塑、增容等角度,阐述了不同助剂,如增容剂、扩链剂及增塑剂等对PGA材料的改性机理,比较了不同增韧材料与PGA材料相容性及界面互溶增强技术;最终总结了PGA加工性能及使用性能的调控规律。

中图分类号:

马超, 马兰荣, 魏辽, 尹慧博, 林祥. 聚乙醇酸材料的加工改性及其水下降解特性的研究进展[J]. 中国塑料, 2022, 36(9): 74-84.

MA Chao, MA Lanrong, WEI Liao, YIN Huibo, LIN Xiang. A review of modification processing and water⁃soluble degradation ability of polyglycolic acid material[J]. China Plastics, 2022, 36(9): 74-84.

| 材料名称 | Tg/℃ | Tm/℃ | 拉伸强度/MPa | 弹性模量/GPa | 断裂伸长率/% | 弯曲强度/MPa | 弯曲模量/GPa |

|---|---|---|---|---|---|---|---|

| PGA[ | 35~40 | 220~230 | 115 | 7 | 16.4 | 222 | 7.8 |

| PLA[ | 57~58 | 140~152 | 53 | 2.4 | 5 | 92 | 3.4 |

| PHA[ | 2~5 | 170 | 50~25 | 1~2 | 4~7 | 33~40 | 1.3~2.0 |

| PBAT[ | -30 | 110~120 | 20 | 0.08 | >900 | 3.1 | 0.08 |

| PCL[ | -60 | 60 | 14.6 | 0.4 | 600~900 | 23.4 | 0.6 |

| PBS[ | -32 | 90~120 | 30 | 17.69 | 600 | 25 | 400 |

| PVA[ | 75~85 | 220~240 | — | — | 15~30 | — | — |

| PHB[ | -1 | 160~170 | 40 | 1.7~3.5 | 3~6 | — | — |

| 材料名称 | Tg/℃ | Tm/℃ | 拉伸强度/MPa | 弹性模量/GPa | 断裂伸长率/% | 弯曲强度/MPa | 弯曲模量/GPa |

|---|---|---|---|---|---|---|---|

| PGA[ | 35~40 | 220~230 | 115 | 7 | 16.4 | 222 | 7.8 |

| PLA[ | 57~58 | 140~152 | 53 | 2.4 | 5 | 92 | 3.4 |

| PHA[ | 2~5 | 170 | 50~25 | 1~2 | 4~7 | 33~40 | 1.3~2.0 |

| PBAT[ | -30 | 110~120 | 20 | 0.08 | >900 | 3.1 | 0.08 |

| PCL[ | -60 | 60 | 14.6 | 0.4 | 600~900 | 23.4 | 0.6 |

| PBS[ | -32 | 90~120 | 30 | 17.69 | 600 | 25 | 400 |

| PVA[ | 75~85 | 220~240 | — | — | 15~30 | — | — |

| PHB[ | -1 | 160~170 | 40 | 1.7~3.5 | 3~6 | — | — |

| 改性方法 | 优点 | 效果 | 缺点 |

|---|---|---|---|

| 增韧 | 同为共混改性,操作方法简单方便,适用于工业化生产 | 加入弹性体增加韧性改善脆性 | 对材料性能改善单一化,只能通过加入改性料来调控材料性能 |

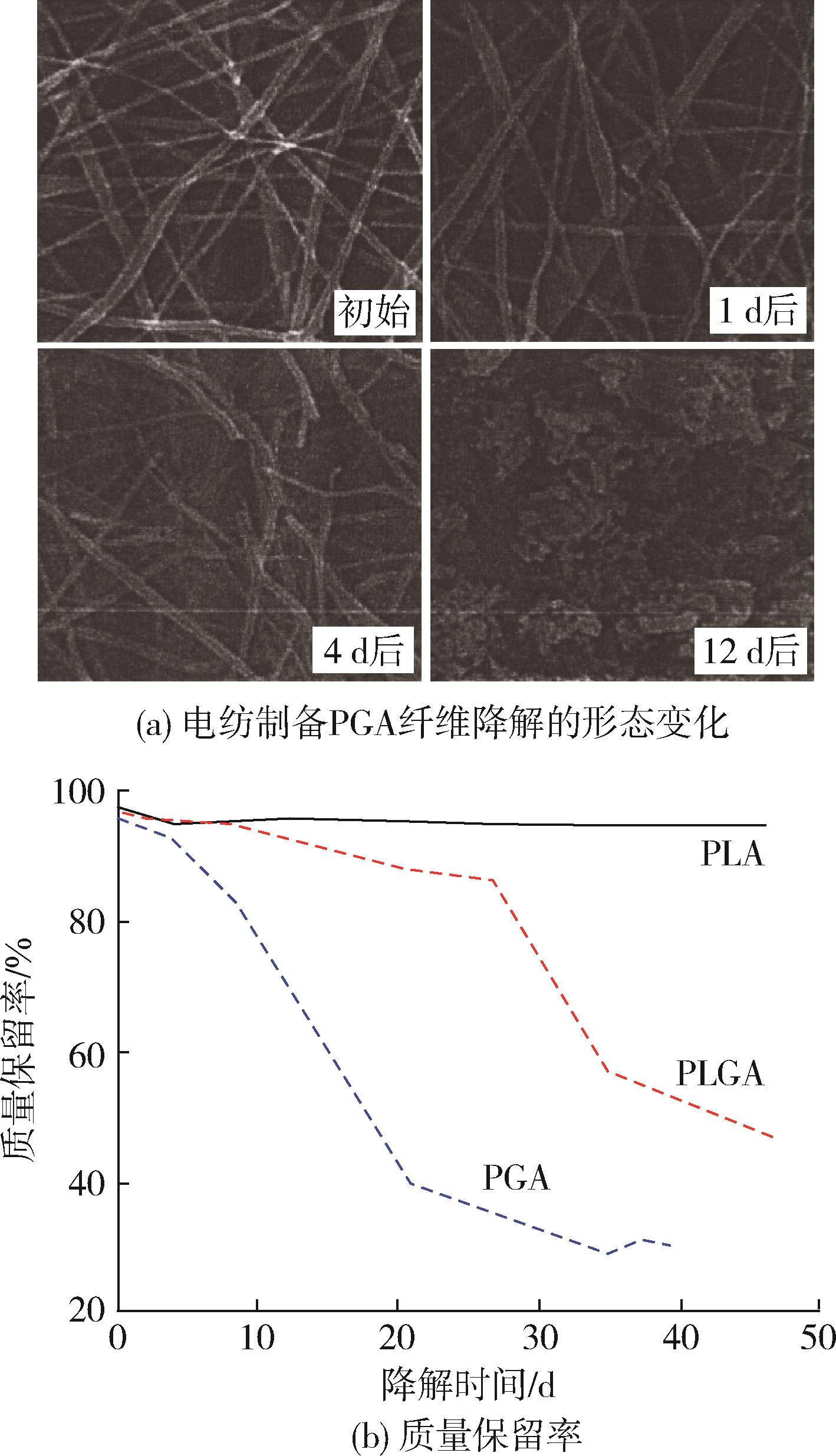

| 增容 | 增加共混物的相容性,强化界面效应,减少相分离 | ||

| 增强 | 加入高强度改性料,提高强度 | ||

| 增塑 | 增加热稳定性,扩大加工窗口 | 可选择性少,多为有毒、污染物,使用限制多 | |

| 溶液改性 | 属于共聚改性,通过调节材料分子结构来达到所需要的性能 | 订制调节材料的降解性能等多种性能 | 过程复杂,成本高,不适于量产 |

| 改性方法 | 优点 | 效果 | 缺点 |

|---|---|---|---|

| 增韧 | 同为共混改性,操作方法简单方便,适用于工业化生产 | 加入弹性体增加韧性改善脆性 | 对材料性能改善单一化,只能通过加入改性料来调控材料性能 |

| 增容 | 增加共混物的相容性,强化界面效应,减少相分离 | ||

| 增强 | 加入高强度改性料,提高强度 | ||

| 增塑 | 增加热稳定性,扩大加工窗口 | 可选择性少,多为有毒、污染物,使用限制多 | |

| 溶液改性 | 属于共聚改性,通过调节材料分子结构来达到所需要的性能 | 订制调节材料的降解性能等多种性能 | 过程复杂,成本高,不适于量产 |

| 1 | 王淑敏, 商宽祥, 谢鸿洲, 等. 聚乙醇酸产业现状及发展前景[J]. 化肥设计, 2021, 59(4): 1⁃4. |

| WANG S M, SHANG K X, XIE H Z,et al. Present situation and development prospect of polyglycolic acid industry[J]. Chemical Fertilizer Design, 2021, 59(4): 1⁃4. | |

| 2 | 刘伯林, 崔华帅, 王金花, 等. 全降解材料聚乙交酯或聚乙醇酸 (PGA) 的发展[J]. 纺织科学研究, 2021,4:58⁃60. |

| 3 | LEE S, HONGO C, NISHINO T. Crystal modulus of poly (glycolic acid) and its temperature dependence [J]. Macromolecules, 2017, 50(13): 5 074⁃5 079. |

| 4 | GAUTIER E, FUERTES P, CASSAGNAU P, et al. Synthesis and rheology of biodegradable poly (glycolic acid) prepared by melt ring‐opening polymerization of glycolide [J]. Journal of Polymer Science Part A: Polymer Chemistry, 2009, 47(5): 1 440⁃1 449. |

| 5 | SAMANTARAY P K, LITTLE A, HADDLETON D M, et al. Poly (glycolic acid)(PGA): A versatile building block expanding high performance and sustainable bioplastic applications [J]. Green Chemistry, 2020, 22(13): 4 055⁃4 081. |

| 6 | CHUJO K, KOBAYASHI H, SUZUKI J, et al. Physical and chemical characteristics polyglycolide [J]. Die Makromolekulare Chemie: Macromolecular Chemistry and Physics, 1967, 100(1): 267⁃270. |

| 7 | FISCHER A M, FREY H. Soluble hyperbranched poly (glycolide) copolymers [J]. Macromolecules, 2010, 43(20): 8 539⁃8 548. |

| 8 | PLACKETT D, SIRÓ I. Polyhydroxyalkanoates (PHAs) for food packaging [M]//Multifunctional and nanoreinforced polymers for food packaging. Woodhead Publishing, 2011: 498⁃526. |

| 9 | JEM K J, POL J F, VOS S. Microbial lactic acid, its polymer poly (lactic acid), and their industrial applications[M]//Plastics from bacteria. Springer, Berlin, Heidelberg, 2010: 323⁃346. |

| 10 | BIRON M. Material selection for thermoplastic parts: practical and advanced information [M]. William Andrew, 2016. |

| 11 | BUGNICOURT E, CINELLI P, LAZZERI A, et al. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging [J]. eXPRESS Polymer Letters,2014, 8(11): 791⁃808. |

| 12 | KUMAR M, MOHANTY S, NAYAK S K, et al. Effect of glycidyl methacrylate (GMA) on the thermal, mechanical and morphological property of biodegradable PLA/PBAT blend and its nanocomposites [J]. Bioresource Technology, 2010, 101(21): 8 406⁃8 415. |

| 13 | AL⁃ITRY R, LAMNAWAR K, MAAZOUZ A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy [J]. Polymer Degradation and Stability, 2012, 97(10): 1 898⁃1 914. |

| 14 | 刘亚丽. 聚丁二酸丁二醇酯增韧改性研究[D].天津:天津科技大学,2015. |

| 15 | LEE S H, WANG S. Biodegradable polymers/bamboo fiber biocomposite with bio⁃based coupling agent [J]. Composites Part A: Applied Science and Manufacturing, 2006, 37(1): 80⁃91. |

| 16 | CHEN G X, KIM H S, KIM E S, et al. Compatibilization⁃like effect of reactive organoclay on the poly (l⁃lactide)/poly (butylene succinate) blends [J]. Polymer, 2005, 46(25): 11 829⁃11 836. |

| 17 | 孙国旗,王维,宋兵,等.聚乙烯醇热塑改性研究进展[J/OL].化工进展, 2022, DOI: 10.16085/j.issn.1000-6613.2021-2574 . |

| SUN G, WANG W, SONG B. Research progress of thermoplastic modification of polyvinyl alcohol [J], Chemi⁃cal Industry and Engineering Progress, 2022, DOI: 10.16085/j.issn.1000-6613.2021-2574 | |

| 18 | HONG S G, HSU H W, YE M T. Thermal properties and applications of low molecular weight polyhydroxybutyrate [J]. Journal of thermal analysis and calorimetry, 2013, 111(2): 1 243⁃1 250. |

| 19 | YAMANE K, SATO H, ICHIKAWA Y, et al. Develo⁃pment of an industrial production technology for high⁃molecular⁃weight polyglycolic acid [J]. Polymer Journal, 2014, 46(11): 769⁃775. |

| 20 | 陈兰兰,孙小杰,王 荣,等. 助剂复配对聚乙醇酸性能的影响[J].塑料工业,2021,4(1):145⁃149. |

| CHEN L L, SUN X J, WANG R, et al. Effect of Additive Compound on the Properties of Polyglycolic acid[J]. China Plastics Industry,2021,4(1):145⁃149. | |

| 21 | SATO H, KOBAYASHI F, KAWAKAMI Y, et al. Process for producing aliphatic polyester reduced in residual cyclic ester content: EP, US8658758 B2 [P]. 2014⁃02⁃25. |

| 22 | NIJENHUIS A J, COLSTEE E, GRIJPMA D W, et al. High molecular weight poly (L⁃lactide) and poly (ethylene oxide) blends: thermal characterization and physical properties [J]. Polymer, 1996, 37(26): 5 849⁃5 857. |

| 23 | CHANG L F, ZHOU Y G, NING Y, et al. Toughening effect of physically blended polyethylene oxide on polyglycolic acid [J]. Journal of Polymers and the Environment, 2020, 28(8): 2 125⁃2 136. |

| 24 | ELLINGFORD C, SAMANTARAY P K, FARRIS S, et al. Reactive extrusion of biodegradable PGA/PBAT blends to enhance flexibility and gas barrier properties [J]. Journal of Applied Polymer Science, 2022, 139(6): 51617. |

| 25 | NIU D, XU P, SUN Z, et al. Superior toughened bio⁃compostable Poly (glycolic acid)⁃based blends with enhanced melt strength via selective interfacial localization of in⁃situ grafted copolymers [J]. Polymer, 2021, 235: 124269. |

| 26 | SHEN J, WANG K, MA Z, et al. Biodegradable blends of poly (butylene adipate‐co‐terephthalate) and polyglycolic acid with enhanced mechanical, rheological and barrier performances [J]. Journal of Applied Polymer Science, 2021, 138(43): 51285. |

| 27 | 贾天飞, 杨海存, 马文中, 等. 相容剂对聚丙烯/聚乙醇酸共混物结构与性能的影响[J]. 化工新型材料, 2019, 47(9): 203⁃206. |

| JIA T F, YANG H C, MA W Z, et al. Influence of compatilizer on the structure and property of PP/PGA[J]. New Chemical Materials, 2019, 47(9): 203⁃206. | |

| 28 | 何敏, 罗兵, 张雅琴, 等. 聚乙醇酸与聚丙烯共混研究[J]. 合成树脂及塑料, 2007, 24(4): 83⁃84. |

| HE M, LUO B, ZHANG Y Q, et al. Study on blending of polyglycolic acid and polypropylene[J]. China Synthetic Resin and Plastics, 2007, 24(4): 83⁃84. | |

| 29 | SAMANTARAY P K, ELLINGFORD C, FARRIS S, et al. Electron beam⁃mediated cross⁃linking of blown film⁃extruded biodegradable PGA/PBAT blends toward high toughness and low oxygen permeation[J]. ACS Sustainable Chemistry & Engineering, 2022,10(3):1 267⁃1 276. |

| 30 | 杨海存, 龚方红, 刘昊天, 等. 混纤纱法制备CGF增强PP/PGA复合材料的性能[J].现代塑料加工应用, 2020, 32(3): 19⁃22. |

| YANG H C, GONG F H, LIU H T, et al. Properties of CGF reinforced PP/PGA composite prepared by commingled roving method[J]. Modern Plastics Processing and Applications, 2020, 32(3): 19⁃22. | |

| 31 | 杨波, 陈蓝天.稳定剂在聚酯生产中的应用[J].聚酯工业,2003(6):5⁃9. |

| YANG B, CHEN L T. Stablizer application in PET production[J]. Polyester Industry,2003(6):5⁃9. | |

| 32 | CHEN L, SUN X, REN Y, et al. Enhancing melt strength of polyglycolic acid by reactive extrusion with chain extenders [J]. Journal of Applied Polymer Science, 2022, 139(11): 51796. |

| 33 | 段雪蕾, 陈兰兰,孙峤昳, 等.改性PGA热稳定性及动力学研究[J].化工新型材料, 2021, 49(S1):210⁃214. |

| DUAN X, Chen L, SUN Q, et al. Investigation on the thermal stability and kinetics of modified PGA [J]. New Chemical Materials, 2021, 49: 210⁃214 | |

| 34 | 乔虎, 张胜, 谷晓昱, 等. 聚乳酸/聚乙醇酸共混合金界面改性研究[J]. 工程塑料应用, 2020,48(1):8⁃12. |

| QIAO H, ZHANG S, GU X Y,et al. Study on interface modification of polylactic acid/polyglycolic acid blend alloy[J]. Engineering Plastics Application, 2020,48(1):8⁃12. | |

| 35 | WANG K, SHEN J, MA Z, et al. Preparation and properties of poly (ethylene glycol⁃co⁃cyclohexane⁃1, 4⁃dimethanol terephthalate)/polyglycolic Acid (PETG/PGA) blends [J]. Polymers, 2021, 13(3): 452. |

| 36 | LIN K, CHUA K N, CHRISTOPHERSON G T, et al. Reducing electrospun nanofiber diameter and variability using cationic amphiphiles [J]. Polymer, 2007, 48(21): 6 384⁃6 394. |

| 37 | YANG J, ZHAN S, WANG N, et al. A mini review: electrospun hierarchical nanofibers [J]. Journal of dispersion science and technology, 2010, 31(6): 760⁃769. |

| 38 | WONG S C, BAJI A, LENG S. Effect of fiber diameter on tensile properties of electrospun poly (ɛ⁃caprolactone) [J]. Polymer, 2008, 49(21): 4 713⁃4 722. |

| 39 | JACOBS V, ANANDJIWALA R D, MAAZA M. The influence of electrospinning parameters on the structural morphology and diameter of electrospun nanofibers [J]. Journal of Applied Polymer Science, 2010, 115(5): 3 130⁃3 136. |

| 40 | SPEARMAN S S, RIVERO I V, ABIDI N. Influence of polycaprolactone/polyglycolide blended electrospun fibers on the morphology and mechanical properties of polycaprolactone [J]. Journal of Applied Polymer Science, 2014, 131(9): 742⁃751. |

| 41 | YOU Y, YOUK J H, LEE S W, et al. Preparation of porous ultrafine PGA fibers via selective dissolution of electrospun PGA/PLA blend fibers [J]. Materials Letters, 2006, 60(6): 757⁃760. |

| 42 | WAHIT M U, HASSAN A, KOAY Y F, et al. Toughening of polyamide 6 nanocomposites: effect of organoclay and maleic anhydride grafted polyethylene octene loading on morphology [J]. International Journal of Mechanical and Materials Engineering, 2009, 4(1): 76⁃87. |

| 43 | LI J, STAYSHICH R M, MEYER T Y. Exploiting sequence to control the hydrolysis behavior of biodegradable PLGA copolymers [J]. Journal of the American Chemical Society, 2011, 133(18): 6 910⁃6 913. |

| 44 | AJIOKA M, SUIZU H, HIGUCHI C, et al. Aliphatic polyesters and their copolymers synthesized through direct condensation polymerization [J]. Polymer Degradation and Stability, 1998, 59(1/3): 137⁃143. |

| 45 | 陈莉, 杜锡光, 赵保中, 等. 聚羟基乙酸及其共聚物[J]. 高分子通报, 2003 (1): 18⁃24. |

| CHEN L, DU X G, ZHAO B Z, et al. The recent development of polyglycolide and its copolmers[J]. Polymer Bulletin, 2003 (1): 18⁃24. | |

| 46 | 赵伟君, 董军, 石道, 等. 利用纳米晶纤维素改性聚乙醇酸的研究[J]. 嘉兴学院学报, 2017, 29(6): 52⁃55. |

| ZHAO W J, DONG J, SHI D, et al. On the modification of poly glycolic acid by nanocrystals cellulose[J]. Journal of Jiaxing University, 2017, 29(6): 52⁃55. | |

| 47 | 沈凯. 乙醇酸的聚合及降解性能研究[D]. 上海:东华大学, 2014. |

| 48 | 汪威雨. 聚乙交酯的水解性能及热稳定的研究[D]. 镇江:江苏科技大学, 2019. |

| 49 | DE JONG S J, ARIAS E R, RIJKERS D T S, et al. New insights into the hydrolytic degradation of poly (lactic acid): participation of the alcohol terminus [J]. Polymer, 2001, 42(7): 2 795⁃2 802. |

| 50 | YOU Y, MIN B M, LEE S J, et al. In vitro degradation behavior of electrospun polyglycolide, polylactide, and poly (lactide‐co‐glycolide) [J]. Journal of Applied Polymer Science, 2005, 95(2): 193⁃200. |

| 51 | 唐四叶,张 瑞,刘 丰,等. 聚乙醇酸熔融水解性能及动力学的研究[J]. 西北大学学报(自然科学版), 2016, 46(1):66⁃70. |

| TANG S Y, ZHANG R, LIU F, et al. Study on hydrolytic degradation and kinetics of polyglycolic acid under melting state[J]. Journal of Northwest University(Natural Science Edition), 2016, 46(1):66⁃70. | |

| 52 | LI S, MCCARTHY S. Further investigations on the hydrolytic degradation of poly (DL⁃lactide) [J]. Biomaterials, 1999, 20(1): 35⁃44. |

| 53 | SCHMITT E A, FLANAGAN D R, LINHARDT R J. Importance of distinct water environments in the hydrolysis of poly (DL⁃lactide⁃co⁃glycolide) [J]. Macromolecules, 1994, 27(3): 743⁃748. |

| 54 | LI S. Hydrolytic degradation characteristics of aliphatic polyesters derived from lactic and glycolic acids [J]. Journal of Biomedical Materials Research: An Official Journal of The Society for Biomaterials, The Japanese Society for Biomaterials, and The Australian Society for Biomaterials, 1999, 48(3): 342⁃353. |

| 55 | 郭正, 张佩华. 编织加工对聚羟基乙酸纤维降解性能的影响[J]. 东华大学学报 (自然科学版), 2009, 35(5): 520⁃524,536. |

| GUO Z, ZHANG P H. Influence of braiding process on the performance of polyglycolic acid fibers during degradation in vitro[J]. Journal of Donghua University(Natural Science), 2009, 35(5): 520⁃524,536. | |

| 56 | SHUM A W T, MAK A F T. Morphological and biomechanical characterization of poly (glycolic acid) scaffolds after in vitro degradation [J]. Polymer Degradation and Stability, 2003, 81(1): 141⁃149. |

| 57 | 田虎虎, 曹鸿璋, 郭立影, 等. 完全生物降解聚乙醇酸研究进展[J]. 橡塑技术与装备, 2021, 47(22): 9⁃15. |

| TIAN H H, CAO H Z, GUO L Y, et al. Research progress of completely biodegradable polyglycolic acid[J]. China Rubber/Plastics Technology and Equipment, 2021, 47(22): 9⁃15. | |

| 58 | LIN X, WANG W, ZHANG W, et al. Hyaluronic acid coating enhances biocompatibility of nonwoven PGA scaffold and cartilage formation[J]. Tissue Engineering Part C: Methods, 2017, 23(2): 86⁃97. |

| 59 | KOBASHI K, VILLMOW T, ANDRES T, et al. Liquid sensing of melt⁃processed poly (lactic acid)/multi⁃walled carbon nanotube composite films [J]. Sensors and Actuators B: Chemical, 2008, 134(2): 787⁃795. |

| 60 | LI K, DAI K, XU X, et al. Organic vapor sensing beha⁃viors of carbon black/poly (lactic acid) conductive biopolymer composite[J]. Colloid and Polymer Science, 2013, 291(12): 2 871⁃2 878. |

| 61 | WU D, LV Q, FENG S, et al. Polylactide composite foams containing carbon nanotubes and carbon black: Synergistic effect of filler on electrical conductivity [J]. Carbon, 2015, 95: 380⁃387. |

| 62 | LEBEDEV S M, GEFLE O S, AMITOV E T, et al. Poly (lactic acid)⁃based polymer composites with high electric and thermal conductivity and their characterization [J]. Polymer Testing, 2017, 58: 241⁃248. |

| 63 | AMELI A, JAHANI D, NOFAR M, et al. Development of high void fraction polylactide composite foams using injection molding: Mechanical and thermal insulation properties [J]. Composites Science and Technology, 2014, 90: 88⁃95. |

| 64 | GONG P, ZHAI S, LEE R, et al. Environmentally friendly polylactic acid⁃based thermal insulation foams blown with supercritical CO2 [J]. Industrial & Enginee⁃ring Chemistry Research, 2018, 57(15): 5 464⁃5 471. |

| 65 | BONUTTI P. Biodegradable packaging material: US. Patent Application 11/123,497[P]. 2005⁃11⁃10. |

| 66 | BOEHM R D, JAIPAN P, SKOOG S A, et al. Inkjet deposition of itraconazole onto poly (glycolic acid) microneedle arrays[J]. Biointerphases, 2016, 11(1): 011008. |

| [1] | 张林, 夏章川, 何亚东, 信春玲, 王瑞雪, 任峰. 等离子体射流载气流量大小对玻璃纤维改性效果影响的研究[J]. 中国塑料, 2022, 36(9): 7-15. |

| [2] | 马国成, 何圳, 陈少军. 醋酸纤维素的降解性研究进展[J]. 中国塑料, 2022, 36(9): 111-121. |

| [3] | 林健辉, 卢嘉慧, 吴欣颖, 范雪滢, 邓桂荣, 高亮, 梅承芳, 杨永刚. 受控堆肥条件下可降解材料最终需氧生物分解能力测定的不确定度评定研究[J]. 中国塑料, 2022, 36(9): 140-147. |

| [4] | 宋丹阳, 郑红娟, 李一龙. 聚乳酸基油水分离材料研究进展[J]. 中国塑料, 2022, 36(9): 187-192. |

| [5] | 杨超永, 郭金强, 王富玉, 张玉霞. 高性能塑料薄膜制备方法及改性研究进展[J]. 中国塑料, 2022, 36(9): 167-179. |

| [6] | 余大荣, 辛勇. 超高分子量聚乙烯改性研究进展[J]. 中国塑料, 2022, 36(8): 135-145. |

| [7] | 喻九阳, 王众浩, 陈琦, 夏亚忠. 基于阀体制造的先进树脂基复合材料性能研究[J]. 中国塑料, 2022, 36(8): 16-22. |

| [8] | 陈佰全, 郑友明, 田际波, 张磊, 王金松, 林夏洁, 段亚鹏. 高含量玻璃纤维增强阻燃聚酰胺材料的制备与性能[J]. 中国塑料, 2022, 36(8): 42-48. |

| [9] | 熊一鸣, 宋季岭, 秦舒浩, 龙雪彬, 鲁显睿. 改性热塑性淀粉的制备及其与PBAT复合薄膜的性能[J]. 中国塑料, 2022, 36(8): 69-72. |

| [10] | 林文, 赵晶晶, 苏婷婷, 王战勇. 聚苯乙烯生物降解研究进展[J]. 中国塑料, 2022, 36(7): 143-149. |

| [11] | 冯凯, 李永青, 马秀清, 韩颖. 聚甲醛增韧改性的研究进展及应用[J]. 中国塑料, 2022, 36(7): 157-164. |

| [12] | 冯冰涛, 王晓珂, 张信, 孙国华, 汪殿龙, 侯连龙, 马劲松. 连续碳纤维增强热塑性复合材料制备与应用研究进展[J]. 中国塑料, 2022, 36(7): 165-173. |

| [13] | 吴雄杰, 朱东波, 孙江波, 高龙美, 储雨, 程劲松, 谢爱迪. 聚乙烯/纳米硫酸钙粉体复合软包装应用性能研究[J]. 中国塑料, 2022, 36(6): 10-15. |

| [14] | 陈轲, 刘鸣飞, 赵彪, 潘凯. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154. |

| [15] | 邵琳颖, 郗悦玮, 翁云宣. 可降解聚乳酸复合材料研究进展[J]. 中国塑料, 2022, 36(6): 155-164. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2