京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (9): 129-136.DOI: 10.19491/j.issn.1001-9278.2024.09.021

• 综述 • 上一篇

崔豹( ), 杨建军(

), 杨建军( ), 吴庆云, 吴明元, 张建安, 刘久逸

), 吴庆云, 吴明元, 张建安, 刘久逸

收稿日期:2023-12-11

出版日期:2024-09-26

发布日期:2024-09-27

通讯作者:

杨建军,教授,主要研究方向:高分子复合材料,andayjj@163.com作者简介:崔豹,硕士研究生,260093746@qq.com

基金资助:

CUI Bao( ), YANG Jianjun(

), YANG Jianjun( ), WU Qingyun, WU Mingyuan, ZHANG Jianan, LIU Jiuyi

), WU Qingyun, WU Mingyuan, ZHANG Jianan, LIU Jiuyi

Received:2023-12-11

Online:2024-09-26

Published:2024-09-27

Contact:

YANG Jianjun

E-mail:260093746@qq.com;andayjj@163.com

摘要:

对可降解材料、纳米材料和聚氨酯等对聚乳酸(PLA)的改性研究进展进行了总结,并对其应用领域进行了归纳,最后进行了展望。

中图分类号:

崔豹, 杨建军, 吴庆云, 吴明元, 张建安, 刘久逸. 聚乳酸复合材料共混改性研究及应用进展[J]. 中国塑料, 2024, 38(9): 129-136.

CUI Bao, YANG Jianjun, WU Qingyun, WU Mingyuan, ZHANG Jianan, LIU Jiuyi. Research Progress in blending modification of polylactic acid composites and their applications[J]. China Plastics, 2024, 38(9): 129-136.

| 1 | Li Xiangrui, Lin Yu, Liu Mingli, et al. A review of research and application of polylactic acid composites [J]. Journal of Applied Polymer Science, 2023, 140(7): e53477 . |

| 2 | Tariq Aziz, Asmat Ullah, Amjad Ali, et al. Manufactures of bio⁃degradable and bio⁃based polymers for bio⁃materials in the pharmaceutical field [J]. Journal of Applied Polymer Science, 2022, 139(29): e52624 . |

| 3 | Han Dequan, Wang Hui, Lu Tingting, et al. Scalable Manufacturing Green Core–Shell Structure Flame Retardant, with Enhanced Mechanical and Flame⁃Retardant Performances of Polylactic Acid [J]. Journal of Polymers and the Environment, 2022, 30(6): 2 516⁃2 533 . |

| 4 | Wu Zecheng, Zhang Zhijun, Wei Wei, et al. Investigation of a novel poly (lactic acid) porous material toughened by thermoplastic polyurethane [J]. Journal of Materials Science, 2022, 57(9): 5 456⁃5 466. |

| 5 | Joanna Ludwiczak, Stanisław Frąckowiak, Karol Leluk. Study of Thermal, Mechanical and Barrier Properties of Biodegradable PLA/PBAT Films with Highly Oriented MMT [J]. Materials, 2021, 14(23): 7 189 . |

| 6 | Cui Congli, Ji Na, Wang Yanfei, et al. Bioactive and intelligent starch⁃based films: A review [J]. Trends in Food Science & Technology, 2021, 116: 854⁃869. |

| 7 | Martinez Villadiego Keydis, Arias Tapia Mary Judith, Useche J, et al. Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review [J]. Journal of Polymers and the Environment, 2022, 30(1): 75⁃91. |

| 8 | Bishwabhusana Palai, Manoranjan Biswal, Smita Mohanty, et al. In situ reactive compatibilization of polylactic acid (PLA) and thermoplastic starch (TPS) blends; synthesis and evaluation of extrusion blown films thereof [J]. Industrial Crops and Products, 2019, 141: 111748 . |

| 9 | Narumol Noivoil, Rangrong Yoksan. Compatibility improvement of poly(lactic acid)/thermoplastic starch blown films using acetylated starch [J]. Journal of Applied Polymer Science, 2021, 138(2): 49675 . |

| 10 | Sharafi Zamir Somayeh, Babak Fathi, Abdellah Ajji, et al. Biodegradation of modified starch/poly lactic acid nanocomposite in soil [J]. Polymer Degradation and Stability, 2022, 199: 109902 . |

| 11 | Chen Haifeng, Dai Chunfa, Long Yue, et al. Enhanced mechanical, thermal, and barrier properties of poly(lactic acid)/starch composite films using gelatinized starch acetate⁃functionalized montmorillonite [J]. Polymer Composites, 2023, 44(2): 1 149⁃1 160. |

| 12 | Ferran Serra⁃Parareda, Marc Delgado⁃Aguilar, Espinach Francesc X, et al. Sustainable plastic composites by polylactic acid⁃starch blends and bleached kraft hardwood fibers [J]. Composites Part B: Engineering, 2022, 238: 109901 . |

| 13 | Eller Haverroth Guilherme, Guenther Soares Bluma. Polypropylene and hollow glass microspheres compatibilization via addition of compatibilizing agents [J]. Polymer Composites, 2021, 42(9): 4 872⁃4 883. |

| 14 | Olaiya N G, Maraveas C, Salem Mohamed A, et al. Viscoelastic and Properties of Amphiphilic Chitin in Plasticised Polylactic Acid/Starch Biocomposite [J]. Polymers, 2022, 14(11): 2 268 . |

| 15 | Farias da Silva Juliana M, Soares Bluma G. Epoxidized cardanol⁃based prepolymer as promising biobased compatibilizing agent for PLA/PBAT blends [J]. Polymer Testing, 2021, 93: 106889 . |

| 16 | Wang Bo, Jin Yujuan, Kang Kai’er, et al. Investigation on compatibility of PLA/PBAT blends modified by epoxy⁃terminated branched polymers through chemical micro⁃crosslinking [J]. 2020, 20(1): 39⁃54 . |

| 17 | Wang Xin, Peng Shaoxian, Chen Hao, et al. Mechanical properties, rheological behaviors, and phase morphologies of high⁃toughness PLA/PBAT blends by in⁃situ reactive compatibilization [J]. Composites Part B: Engineering, 2019, 173: 107028 . |

| 18 | Han Yi, Shi Jinwei, Mao Lixin, et al. Improvement of Compatibility and Mechanical Performances of PLA/PBAT Composites with Epoxidized Soybean Oil as Compatibilizer [J]. Industrial & Engineering Chemistry Research, 2020, 59(50): 21 779⁃21 790. |

| 19 | Sun Ce, Li Changxin, Li Haiying, et al. Modified Cellulose Nanocrystals Enhanced the Compatibility Between PLA and PBAT to Prepare a Multifunctional Composite Film [J]. Journal of Polymers and the Environment, 2022, 30(8): 3 139⁃3 149. |

| 20 | Song Jie, Zhang Rong, Li Shenggang, et al. Properties of phosphorus⁃containing polybutylene succinate/polylactic acid composite film material and degradation process effects on physiological indexes of lettuce cultivation [J]. Polymer Testing, 2023, 119: 107921. |

| 21 | Zhang Meng, Jiang Chao, Wu Qiuhua, et al. Poly(lactic acid)/Poly(butylene succinate) (PLA/PBS) Layered Composite Gas Barrier Membranes by Anisotropic Janus Nanosheets Compartibilizers [J]. ACS Macro Letters, 2022, 11(5): 657⁃662. |

| 22 | Fan Zhiqiang, Gao Junchang, Wu Yadong, et al. Highly Enhanced Mechanical, Thermal, and Crystallization Performance of PLA/PBS Composite by Glass Fiber Coupling Agent Modification [J]. Polymers, 2023, 15(15): 3 164. |

| 23 | He Lu, Song Fei, Li De⁃Fu, et al. Strong and Tough Polylactic Acid Based Composites Enabled by Simultaneous Reinforcement and Interfacial Compatibilization of Microfibrillated Cellulose [J]. ACS Sustainable Chemistry & Engineering, 2020, 8(3): 1 573⁃1 582. |

| 24 | da Cruz Faria Érica, Dias Marcos Lopes, Ferreira Luana Marques, et al. Crystallization behavior of zinc oxide/poly(lactic acid) nanocomposites [J]. Journal of Thermal Analysis and Calorimetry, 2021, 146(4): 1 483⁃1 490. |

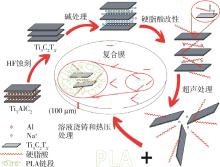

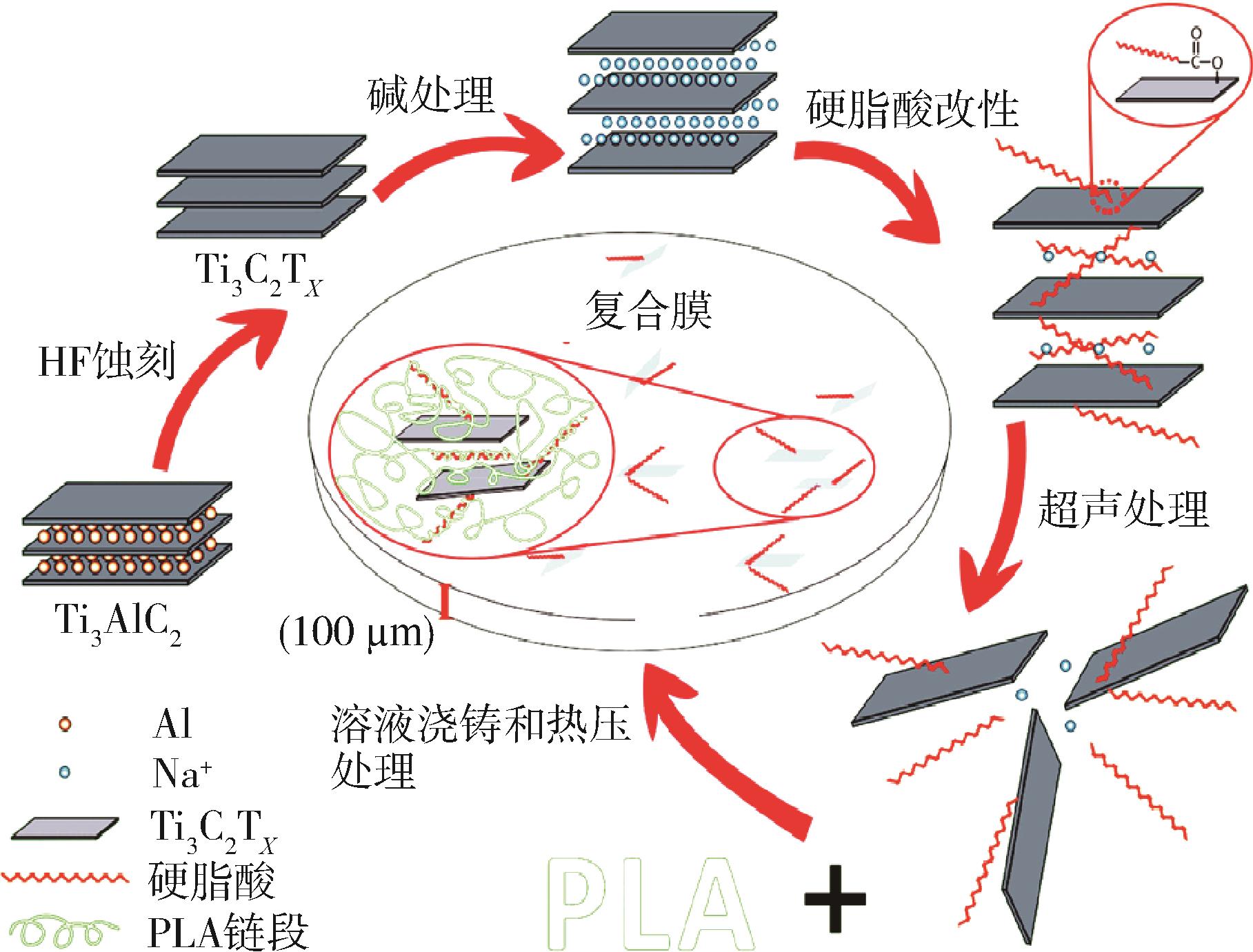

| 25 | Yi Zhuwu, Yang Jian, Liu Xiaochao, et al. Enhanced mechanical properties of poly(lactic acid) composites with ultrathin nanosheets of MXene modified by stearic acid [J]. Journal of Applied Polymer Science, 2020, 137(17): 48621. |

| 26 | Jamileh Shojaeiarani, Dilpreet Bajwa, Jiang Long, et al. Insight on the influence of nano zinc oxide on the thermal, dynamic mechanical, and flow characteristics of Poly(lactic acid)– zinc oxide composites [J]. Polymer Engineering & Science, 2019, 59(6): 1 242⁃1 249. |

| 27 | Nattinee Bumbudsanpharoke, Jeongin Choi, Hyun Jin Park, et al. Zinc migration and its effect on the functionality of a low density polyethylene⁃ZnO nanocomposite film [J]. Food Packaging and Shelf Life, 2019, 20: 100301 . |

| 28 | Tang Zhenya, Fan Fangling, Chu Zhuangzhuang, et al. Barrier Properties and Characterizations of Poly(lactic Acid)/ZnO Nanocomposites [J]. Molecules, 2020, 25(6): 1 310 . |

| 29 | Akshaykranth A, Jayarambabu N, Venkatappa Rao T, et al. Influence of MgO and ZnO nanofillers on morphology, structural, thermal and mechanical properties of polylactic acid films [J]. Bulletin of Materials Science, 2022, 45(4): 247. |

| 30 | Verginio Gleice Ellen Almeida, Montanheiro Thais Larissa do Amaral, Montagna Larissa Stieven, et al. Effectiveness of the preparation of maleic anhydride grafted poly (lactic acid) by reactive processing for poly (lactic acid)/carbon nanotubes nanocomposites [J]. Journal of Applied Polymer Science, 2021, 138(12): 50087. |

| 31 | Bai Tiantian, Zhu Bo, Liu Hu, et al. Biodegradable poly(lactic acid) nanocomposites reinforced and toughened by carbon nanotubes/clay hybrids [J]. International Journal of Biological Macromolecules, 2020, 151: 628⁃634. |

| 32 | Simonini L, Mahmood H, Dorigato A, et al. Tailoring the physical properties of poly(lactic acid) through the addition of thermoplastic polyurethane and functionalized short carbon fibers [J]. Polymer Composites, 2023, 44(8): 4 719⁃4 733. |

| 33 | Yi⁃Sheng Jhao, Ouyang Hao, Yang Fuqian, et al. Thermo⁃Mechanical and Creep Behaviour of Polylactic Acid/Thermoplastic Polyurethane Blends [J]. Polymers, 2022, 14(23): 5 276. |

| 34 | Sun Mingtao, Huang Shuang, Yu Muhuo, et al. Toughening Modification of Polylactic Acid by Thermoplastic Silicone Polyurethane Elastomer [J]. Polymers, 2021, 13(12): 1 953. |

| 35 | Su Xiaolong, Jia Shikui, Cao Le, et al. High performance polylactic acid/thermoplastic polyurethane blends with in⁃situ fibrillated morphology [J]. Journal of Applied Polymer Science, 2021, 138(39): 51014. |

| 36 | Fang Hui, Zhang Lingjie, Chen Anlin, et al. Improvement of Mechanical Property for PLA/TPU Blend by Adding PLA⁃TPU Copolymers Prepared via In Situ Ring⁃Opening Polymerization [J]. Polymers, 2022, 14(8): 1 530. |

| 37 | Wu Jia⁃hui, Hu Teng⁃gen, Wang Hong, et al. Electrospinning of PLA Nanofibers: Recent Advances and Its Potential Application for Food Packaging [J]. Journal of Agricultural and Food Chemistry, 2022, 70(27): 8 207⁃8 221. |

| 38 | Gao Chuanhui, Chen Picheng, Ma Ying, et al. Multifunctional polylactic acid biocomposite film for active food packaging with UV resistance, antioxidant and antibacterial properties [J]. International Journal of Biological Macromolecules, 2023, 253: 126494. |

| 39 | Li Chao, Wang Bo, Shang Zuming, et al. High⁃Barrier Poly(butylene succinate⁃co⁃terephthalate) Blend with Poly(lactic acid) as Biodegradable Food Packaging Films [J]. Industrial & Engineering Chemistry Research, 2023, 62(18): 7 250⁃7 261. |

| 40 | Farnoosh Ebrahimi, Ramezani Dana Hossein. Poly lactic acid (PLA) polymers: from properties to biomedical applications [J]. International Journal of Polymeric Materials and Polymeric Biomaterials, 2022, 71(15): 1 117⁃1 130. |

| 41 | Liu Shan, Qin Shuhao, He Min, et al. Current applications of poly(lactic acid) composites in tissue engineering and drug delivery [J]. Composites Part B: Engineering, 2020, 199: 108238. |

| 42 | Chen Kuan⁃Jen, Fei⁃Yi Hung, Wang Yun⁃Ting, et al. Mechanical properties and biomedical application characteristics of degradable polylactic acid–Mg–Ca3(PO4)2 three⁃phase composite [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2022, 125: 104949. |

| 43 | Luo Weihua, Cheng Lianghao, Yuan Caixia, et al. Preparation, characterization and evaluation of cellulose nanocrystal/poly(lactic acid) in situ nanocomposite scaffolds for tissue engineering [J]. International Journal of Biological Macromolecules, 2019, 134: 469⁃479. |

| 44 | Mehran Jafari, Eunkyoung Shim, Abhay Joijode. Fabrication of Poly(lactic acid) filter media via the meltblowing process and their filtration performances: A comparative study with polypropylene meltblown [J]. Separation and Purification Technology, 2021, 260: 118185. |

| 45 | Liu Gaohui, Guan Jie, Wang Xianfeng, et al. Polylactic Acid (PLA) Melt⁃Blown Nonwovens with Superior Mechanical Properties [J]. ACS Sustainable Chemistry & Engineering, 2023, 11(10): 4 279⁃4 288. |

| 46 | Feng Yujie, Wang Na, He Tian, et al. Ag/Zn Galvanic Couple Cotton Nonwovens with Breath⁃Activated Electroactivity: A Possible Antibacterial Layer for Personal Protective Face Masks [J]. ACS Applied Materials & Interfaces, 2021, 13(49): 59 196⁃59 205. |

| 47 | Hu Rui, Huang Qiwei, Liu Gaohui, et al. Polylactic Acid/Calcium Stearate Hydrocharging Melt⁃Blown Nonwoven Fabrics for Respirator Applications [J]. ACS Applied Polymer Materials, 2023, 5(6): 4 372⁃4 379. |

| 48 | Stefano Cairone, Hegab Hanaa M, Hiyam Khalil, et al. Novel eco⁃friendly polylactic acid nanocomposite integrated membrane system for sustainable wastewater treatment: Performance evaluation and antifouling analysis [J]. Science of The Total Environment, 2023, 912: 168715. |

| 49 | Zhang Di, Jin Xin⁃Zheng, Huang Ting, et al. Electrospun Fibrous Membranes with Dual⁃Scaled Porous Structure: Super Hydrophobicity, Super Lipophilicity, Excellent Water Adhesion, and Anti⁃Icing for Highly Efficient Oil Adsorption/Separation [J]. ACS Applied Materials & Interfaces, 2019, 11(5): 5 073⁃5 083. |

| 50 | Chen Tianchi, Guo Jie, Xu Hao, et al. One⁃step fabrication of biodegradable superhydrophobic PLA fabric for continuous oil/water separation [J]. Applied Surface Science, 2022, 576: 151766. |

| [1] | 文麒霖, 贾雪华, 孙炎君, 牛思霁, 陈英红, 陈宁. 生物可降解塑料包装薄膜的制备及应用进展[J]. 中国塑料, 2024, 38(9): 112-122. |

| [2] | 董光, 侯仰喆, 袁洪跃, 刘宪虎, 潘亚敏. 多孔聚乳酸材料的制备及结构性能优化进展[J]. 中国塑料, 2024, 38(8): 132-140. |

| [3] | 刘顺权, 张馨月, 冯占苗, 傅陈超, 薛平, 张润. PTFE改性技术及其性能优化研究进展[J]. 中国塑料, 2024, 38(7): 112-119. |

| [4] | 胡永祥, 谢纪岭, 李伟铭, 张璐, 汤香港, 吕亿同, 申红望, 鞠冠男. 马来酸酐接枝改性GTR对聚乳酸性能的影响[J]. 中国塑料, 2024, 38(7): 20-24. |

| [5] | 王杰, 辛德华, 李晖, 蒋洪石, 周洪福, 赵建国. 纳米黏土与二氧化硅协同改性聚乳酸研究[J]. 中国塑料, 2024, 38(7): 43-48. |

| [6] | 赵永飞, 张文才, 王科, 郝晓刚, 申峻, 杨喜英, 赵丽荣, 李建红, 赵志新, 乔杰. 废弃聚乙烯改性剂改性沥青研究及其应用技术进展[J]. 中国塑料, 2024, 38(7): 93-99. |

| [7] | 骆佳伟, 周炳, 王洪学, 贾钦. 扩链条件对聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯/滑石粉共混物性能的影响[J]. 中国塑料, 2024, 38(6): 1-11. |

| [8] | 苏羽航, 周宇鸿, 林渊智, 毛健全, 王永祥, 刘向, 余立, 柯俊沐. 弹性体对PP/EVA无胶复合膜性能影响研究[J]. 中国塑料, 2024, 38(6): 44-50. |

| [9] | 张正, 李方全, 李杰, 李长金, 郭敏, 王颖. 聚酰胺在医用卫生材料中的应用及研究进展[J]. 中国塑料, 2024, 38(5): 113-119. |

| [10] | 杨超永, 郭金强, 王富玉, 张玉霞. 挤出吹塑工艺对PBAT/PLA共混体系微观结构与性能的影响[J]. 中国塑料, 2024, 38(5): 82-87. |

| [11] | 孛海娃, 赵中国, 王筹萱, 薛嵘. 高导电、低逾渗PLA/CNTs导电复合材料的结构设计及性能研究[J]. 中国塑料, 2024, 38(4): 13-18. |

| [12] | 沈丹彤, 薛雨亭, 李荣杰, 徐芳, 翁云宣. 聚乳酸基水性聚氨酯的制备及其在合成革中的应用研究[J]. 中国塑料, 2024, 38(4): 19-25. |

| [13] | 戚士界, 游翔宇, 王瑞晨, 周琳菲, 张慧洁. 高木质素含量聚乳酸共混材料的制备及其性能研究[J]. 中国塑料, 2024, 38(2): 45-51. |

| [14] | 谭晶, 王智, 王朔, 付宏岩, 李长金, 李好义, 杨卫民, 张杨. 树枝状聚合物对聚乳酸熔体微分电纺纤维膜的增韧改性研究[J]. 中国塑料, 2024, 38(2): 7-13. |

| [15] | 马秀清, 劳志超, 李明谦, 韩顺涛, 胡楠. 3D打印工艺参数对PLA/PTW共混物力学性能影响的研究[J]. 中国塑料, 2024, 38(2): 70-75. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2