京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (6): 108-115.DOI: 10.19491/j.issn.1001-9278.2022.06.017

董少策1,2, 李承高1,2, 张旭锋3, 咸贵军1,2( )

)

收稿日期:2021-12-13

出版日期:2022-06-26

发布日期:2022-06-27

通讯作者:

咸贵军(1972-),男,教授,博士生导师,主要从事纤维增强复合材料及其结构的制备及耐久性研究,gjxian@hit.edu.cn基金资助:

DONG Shaoce1,2, LI Chenggao1,2, ZHANG Xufeng3, XIAN Guijun1,2( )

)

Received:2021-12-13

Online:2022-06-26

Published:2022-06-27

Contact:

XIAN Guijun

E-mail:gjxian@hit.edu.cn

摘要:

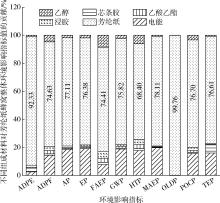

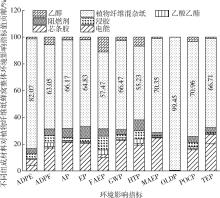

利用CML环境影响评价方法,研究并比较了植物纤维纸蜂窝和传统芳纶纸蜂窝制备的环境影响。结果表明,针对所涉及的11个环境影响指标,植物纤维纸蜂窝低于芳纶纸蜂窝0.68 %~49.41 %;权重化结果表明,植物纤维纸蜂窝制备环境影响总体低于芳纶纸蜂窝18.77 %;制备芳纶纸蜂窝的环境影响主要来自于芳纶纸和电能的消耗;制备植物纤维纸蜂窝的环境影响主要来自于混杂纸和电能的生产。

中图分类号:

董少策, 李承高, 张旭锋, 咸贵军. 植物纤维纸蜂窝制备的环境影响评价[J]. 中国塑料, 2022, 36(6): 108-115.

DONG Shaoce, LI Chenggao, ZHANG Xufeng, XIAN Guijun. Environmental impact assessment for manufacture of plant fiber honeycomb core[J]. China Plastics, 2022, 36(6): 108-115.

| 环境影响类别指标 | 权重值 |

|---|---|

| ADPE/kg Sb eq | 6.4 |

| ADPF/MJ | 7 |

| AP/kg SO2 eq | 6.1 |

| EP/kg P eq | 6.6 |

| FAEP/kg DCB eq | 6.8 |

| GWP/kg CO2 eq | 9.3 |

| HTP/kg DCB eq | 7.1 |

| MAEP/kg DCB eq | 6.8 |

| OLDP/kg R11 eq | 6.2 |

| POCP/kg Ethene eq | 6.5 |

| TEP/kg DCB eq | 6.8 |

| 环境影响类别指标 | 权重值 |

|---|---|

| ADPE/kg Sb eq | 6.4 |

| ADPF/MJ | 7 |

| AP/kg SO2 eq | 6.1 |

| EP/kg P eq | 6.6 |

| FAEP/kg DCB eq | 6.8 |

| GWP/kg CO2 eq | 9.3 |

| HTP/kg DCB eq | 7.1 |

| MAEP/kg DCB eq | 6.8 |

| OLDP/kg R11 eq | 6.2 |

| POCP/kg Ethene eq | 6.5 |

| TEP/kg DCB eq | 6.8 |

| 环境影响类别指标 | 芳纶纸蜂窝/1 kg | 植物纤维纸蜂窝/1 kg | 植物纤维纸蜂窝环境影响指标降低率/ % |

|---|---|---|---|

| ADPE/kg Sb eq | 3.35×10-5 | 1.99×10-5 | 40.64 |

| ADPF/MJ | 7.73×102 | 6.53×102 | 15.57 |

| AP/kg SO2 eq | 7.92×10-2 | 6.96×10-2 | 12.16 |

| EP/kg P eq | 1.17×10-2 | 1.09×10-2 | 6.57 |

| FAEP/kg DCB eq | 9.17×10-2 | 7.10×10-2 | 22.52 |

| GWP/kg CO2 eq | 59.34 | 49.60 | 16.38 |

| HTP/kg DCB eq | 1.71 | 1.57 | 7.88 |

| MAEP/kg DCB eq | 3.19×103 | 2.57×103 | 19.48 |

| OLDP/kg R11 eq | 1.21×10-9 | 6.11×10-10 | 49.41 |

| POCP/kg Ethene eq | 7.52×10-3 | 7.47×10-3 | 0.68 |

| TEP/kg DCB eq | 3.83×10-2 | 3.02×10-2 | 21.31 |

| 环境影响类别指标 | 芳纶纸蜂窝/1 kg | 植物纤维纸蜂窝/1 kg | 植物纤维纸蜂窝环境影响指标降低率/ % |

|---|---|---|---|

| ADPE/kg Sb eq | 3.35×10-5 | 1.99×10-5 | 40.64 |

| ADPF/MJ | 7.73×102 | 6.53×102 | 15.57 |

| AP/kg SO2 eq | 7.92×10-2 | 6.96×10-2 | 12.16 |

| EP/kg P eq | 1.17×10-2 | 1.09×10-2 | 6.57 |

| FAEP/kg DCB eq | 9.17×10-2 | 7.10×10-2 | 22.52 |

| GWP/kg CO2 eq | 59.34 | 49.60 | 16.38 |

| HTP/kg DCB eq | 1.71 | 1.57 | 7.88 |

| MAEP/kg DCB eq | 3.19×103 | 2.57×103 | 19.48 |

| OLDP/kg R11 eq | 1.21×10-9 | 6.11×10-10 | 49.41 |

| POCP/kg Ethene eq | 7.52×10-3 | 7.47×10-3 | 0.68 |

| TEP/kg DCB eq | 3.83×10-2 | 3.02×10-2 | 21.31 |

| 环境影响类别指标 | 电能 | 芯条胶 | 乙酸乙酯 | 浸胶 | 芳纶纸 | 乙醇 |

|---|---|---|---|---|---|---|

| ADPE/kg Sb eq | 8.50×10-7 | 9.14×10-7 | 1.10×10-7 | 4.35×10-7 | 3.10×10-5 | 2.65×10-7 |

| ADPF/MJ | 1.12×102 | 7.50 | 18.38 | 22.08 | 5.77×102 | 36.57 |

| AP/kg SO2 eq | 1.47×10-2 | 4.21×10-4 | 6.27×10-4 | 9.24×10-4 | 6.11×10-2 | 1.45×10-3 |

| EP/kg P eq | 2.23×10-3 | 7.76×10-5 | 9.75×10-5 | 1.37×10-4 | 8.94×10-3 | 2.18×10-4 |

| FAEP/kg DCB eq | 7.20×10-3 | 1.43×10-3 | 2.54×10-3 | 4.48×10-3 | 6.82×10-2 | 7.82×10-3 |

| GWP/kg CO2 eq | 11.19 | 0.36 | 0.73 | 0.75 | 44.99 | 1.31 |

| HTP/kg DCB eq | 0.30 | 2.26×10-2 | 5.18×10-2 | 5.79×10-2 | 1.17 | 0.10 |

| MAEP/kg DCB eq | 6.32×102 | 12.68 | 10.44 | 17.65 | 2.49×103 | 26.44 |

| OLDP/kg R11 eq | 2.56×10-12 | 1.16×10-13 | 4.50×10-14 | 1.05×10-13 | 1.20×10-9 | 8.19×10-14 |

| POCP/kg Ethene eq | 1.18×10-3 | 6.21×10-5 | 1.04×10-4 | 1.57×10-4 | 5.76×10-3 | 2.50×10-4 |

| TEP/kg DCB eq | 6.12×10-3 | 2.27×10-3 | 9.55×10-5 | 2.17×10-4 | 2.94×10-2 | 2.67×10-4 |

| 环境影响类别指标 | 电能 | 芯条胶 | 乙酸乙酯 | 浸胶 | 芳纶纸 | 乙醇 |

|---|---|---|---|---|---|---|

| ADPE/kg Sb eq | 8.50×10-7 | 9.14×10-7 | 1.10×10-7 | 4.35×10-7 | 3.10×10-5 | 2.65×10-7 |

| ADPF/MJ | 1.12×102 | 7.50 | 18.38 | 22.08 | 5.77×102 | 36.57 |

| AP/kg SO2 eq | 1.47×10-2 | 4.21×10-4 | 6.27×10-4 | 9.24×10-4 | 6.11×10-2 | 1.45×10-3 |

| EP/kg P eq | 2.23×10-3 | 7.76×10-5 | 9.75×10-5 | 1.37×10-4 | 8.94×10-3 | 2.18×10-4 |

| FAEP/kg DCB eq | 7.20×10-3 | 1.43×10-3 | 2.54×10-3 | 4.48×10-3 | 6.82×10-2 | 7.82×10-3 |

| GWP/kg CO2 eq | 11.19 | 0.36 | 0.73 | 0.75 | 44.99 | 1.31 |

| HTP/kg DCB eq | 0.30 | 2.26×10-2 | 5.18×10-2 | 5.79×10-2 | 1.17 | 0.10 |

| MAEP/kg DCB eq | 6.32×102 | 12.68 | 10.44 | 17.65 | 2.49×103 | 26.44 |

| OLDP/kg R11 eq | 2.56×10-12 | 1.16×10-13 | 4.50×10-14 | 1.05×10-13 | 1.20×10-9 | 8.19×10-14 |

| POCP/kg Ethene eq | 1.18×10-3 | 6.21×10-5 | 1.04×10-4 | 1.57×10-4 | 5.76×10-3 | 2.50×10-4 |

| TEP/kg DCB eq | 6.12×10-3 | 2.27×10-3 | 9.55×10-5 | 2.17×10-4 | 2.94×10-2 | 2.67×10-4 |

| 环境影响类别指标 | 电能 | 芯条胶 | 乙酸乙酯 | 浸胶 | 阻燃剂 | 植物纤维混杂纸 | 乙醇 |

|---|---|---|---|---|---|---|---|

| ADPE/kg Sb eq | 8.50×10-7 | 8.68×10-7 | 1.11×10-7 | 7.12×10-7 | 7.62×10-7 | 1.63×10-5 | 2.66×10-7 |

| ADPF/MJ | 1.12×102 | 7.13 | 18.58 | 36.16 | 30.93 | 4.12×102 | 36.76 |

| AP/kg SO2 eq | 1.47×10-2 | 4.00×10-4 | 6.34×10-4 | 1.51×10-3 | 4.82×10-3 | 4.61×10-2 | 1.46×10-3 |

| EP/kg P eq | 2.23×10-3 | 7.38×10-5 | 9.85×10-5 | 2.24×10-4 | 9.96×10-4 | 7.09×10-3 | 2.19×10-4 |

| FAEP/kg DCB eq | 7.20×10-3 | 1.36×10-3 | 2.56×10-3 | 7.33×10-3 | 3.90×10-3 | 4.08×10-2 | 7.86×10-3 |

| GWP/kg CO2 eq | 11.19 | 0.34 | 0.74 | 1.22 | 1.82 | 32.98 | 1.32 |

| HTP/kg DCB eq | 0.30 | 2.15×10-2 | 5.23×10-2 | 9.47×10-2 | 0.13 | 0.87 | 0.10 |

| MAEP/kg DCB eq | 6.32×102 | 12.05 | 10.55 | 28.91 | 52.57 | 1.81×103 | 26.58 |

| OLDP/kg R11 eq | 2.56×10-12 | 1.10×10-13 | 4.55×10-14 | 1.71×10-13 | 3.79×10-13 | 6.07×10-10 | 8.23×10-14 |

| POCP/kg Ethene eq | 1.18×10-3 | 5.90×10-5 | 1.05×10-4 | 2.57×10-4 | 3.17×10-4 | 5.30×10-3 | 2.52×10-4 |

| TEP/kg DCB eq | 6.12×10-3 | 2.15×10-3 | 9.65×10-5 | 3.56×10-4 | 1.05×10-3 | 2.01×10-2 | 2.68×10-4 |

| 环境影响类别指标 | 电能 | 芯条胶 | 乙酸乙酯 | 浸胶 | 阻燃剂 | 植物纤维混杂纸 | 乙醇 |

|---|---|---|---|---|---|---|---|

| ADPE/kg Sb eq | 8.50×10-7 | 8.68×10-7 | 1.11×10-7 | 7.12×10-7 | 7.62×10-7 | 1.63×10-5 | 2.66×10-7 |

| ADPF/MJ | 1.12×102 | 7.13 | 18.58 | 36.16 | 30.93 | 4.12×102 | 36.76 |

| AP/kg SO2 eq | 1.47×10-2 | 4.00×10-4 | 6.34×10-4 | 1.51×10-3 | 4.82×10-3 | 4.61×10-2 | 1.46×10-3 |

| EP/kg P eq | 2.23×10-3 | 7.38×10-5 | 9.85×10-5 | 2.24×10-4 | 9.96×10-4 | 7.09×10-3 | 2.19×10-4 |

| FAEP/kg DCB eq | 7.20×10-3 | 1.36×10-3 | 2.56×10-3 | 7.33×10-3 | 3.90×10-3 | 4.08×10-2 | 7.86×10-3 |

| GWP/kg CO2 eq | 11.19 | 0.34 | 0.74 | 1.22 | 1.82 | 32.98 | 1.32 |

| HTP/kg DCB eq | 0.30 | 2.15×10-2 | 5.23×10-2 | 9.47×10-2 | 0.13 | 0.87 | 0.10 |

| MAEP/kg DCB eq | 6.32×102 | 12.05 | 10.55 | 28.91 | 52.57 | 1.81×103 | 26.58 |

| OLDP/kg R11 eq | 2.56×10-12 | 1.10×10-13 | 4.55×10-14 | 1.71×10-13 | 3.79×10-13 | 6.07×10-10 | 8.23×10-14 |

| POCP/kg Ethene eq | 1.18×10-3 | 5.90×10-5 | 1.05×10-4 | 2.57×10-4 | 3.17×10-4 | 5.30×10-3 | 2.52×10-4 |

| TEP/kg DCB eq | 6.12×10-3 | 2.15×10-3 | 9.65×10-5 | 3.56×10-4 | 1.05×10-3 | 2.01×10-2 | 2.68×10-4 |

| 1 | 马科峰, 张广成, 刘良威, 等. 夹层结构复合材料的吸波隐身技术研究进展[J]. 材料开发与应用, 2010, 25(6): 53⁃57. |

| MA K, ZHANG G, LIU L, et al. Research progress of technology for sandwich structural absorbing stealthy composite materials[J]. Development and Application of Materials, 2010, 25(6):53⁃57. | |

| 2 | 黄钧铭, 孙茂健, 朱敏英, 等. 蜂窝结构材料用国产芳纶纸性能分析[J]. 高科技纤维与应用, 2008, 33(6): 33⁃38 |

| HUANG J, SUN M, ZHU M, et al. Performance analysis of the domestic meta⁃aramid paper (pmia) used for honeycomb structure material[J]. Hi⁃Tech Fiber and Application, 2008, 33(6):33⁃38. | |

| 3 | 郝巍, 罗玉清. 国产间位芳纶纸蜂窝性能的研究[J]. 高科技纤维与应用, 2009, 34(6): 26⁃30. |

| HAO W, LUO Y. Study on the properties of china's meta⁃aramid paper honeycomb[J]. Hi⁃Tech Fiber and Application, 2009, 34(6):26⁃30. | |

| 4 | 李瑞敏, 刘杰, 罗玉清, 等. 植物纤维纸蜂窝芯材的制备及性能[J]. 工程塑料应用, 2017, 45(8): 55⁃59+69. |

| LI R, LIU J, LUO Y, et al. Preparation and properties of plant fiber honeycomb core[J]. Engineering Plastics Application, 2017, 45(8): 55⁃59+69. | |

| 5 | 余金光, 马兴运, 张旭锋, 等. 植物纤维纸蜂窝的性能研究[J]. 航空制造技术, 2018, 61(10): 80⁃83. |

| YU J, MA X, ZHANG X, et al. Performance analysis of the domestic meta⁃aramid paper (pmia) used for honeycomb structure material[J]. Aeronautical Manufacturing Technology, 2018, 61(10):80⁃83. | |

| 6 | NICOLLIER C T, LABAN G B, LUNDQUIST L, et al. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics [J]. Resources Conservation & Recycling, 2001, 33(4): 267⁃287. |

| 7 | STRATTON W R, WOLFE P J, HILEMAN J I. Impact of aviation non⁃CO2 combustion effects on the environmental feasibility of alternative jet fuels [J]. Environmental Science & Technology, 2011, 45(24): 10 736⁃10 743. |

| 8 | AGUSDINATE B D, ZHAO F, LLELEJI K, et al. Life cycle assessment of potential biojet fuel production in the United States [J]. Environmental Science & Technology, 2011, 45(21): 9 133⁃9 143. |

| 9 | FORTIER M O P, ROBERTS W G, WILLIAMS S M S, et al. Life cycle assessment of bio⁃jet fuel from hydrothermal liquefaction of microalgae [J]. Applied Energy, 2014, 122: 73⁃82. |

| 10 | COX K, RENOUF M, DARGAN A, et al. Environmental life cycle assessment (LCA) of aviation biofuel from microalgae, pongamiapinnata, and sugarcane molasses [J]. Biofuels, Bioproducts and Biorefining, 2014, 8(4): 579⁃593. |

| 11 | FENG P P, KINSEL W C, THAL A E, et al. Jet propellant 8 versus alternative jet fuels: a life⁃cycle perspective [J]. Air & Space Power Journal, 2011, 25(2): 47⁃56. |

| 12 | FAN J, SHONNARD D R, KALNES T N, et al. A life cycle assessment of pennycress (thlaspiarvense l.)⁃derived jet fuel and diesel [J]. Biomass and Bioenergy, 2013, 55: 87⁃100. |

| 13 | BECK J A, HODZIC A, SOUTIS C, et al. Influence of implementation of composite materials in civil aircraft industry on reduction of environmental pollution and greenhouse effect [C]. London: IOP Publishing Ltd, 2011:1⁃9. |

| 14 | LIU Z. Life cycle assessment of composites and aluminium use in aircraft systems [D]. Cranfield: Cranfielduniversity, 2013. |

| 15 | VIDAL R, MOLINER E, MARTIN P P, et al. Life cycle assessment of novel aircraft interior panels made from renewable or recyclable polymers with natural fiber reinforcements and non‐halogenated flame retardants [J]. Journal of Industrial Ecology, 2017, 22(1): 132⁃144. |

| 16 | ISO. Environmental management⁃life cycle assessment⁃principles and framework: [S]. [2021⁃9⁃29]. . |

| 17 | ISO. Environmental management⁃life cycle assessment⁃requirements and guidelines: [S].[2021⁃9⁃29]. . |

| 18 | Centre of Environmental Science, Leiden University (CML) and National Institute of Public Health and Environmental Protection (RIVM). LCA impact assessment of toxic releases: generic modelling of fate, exposure and effect for ecosystems and human beings with data for about 100 chemicals [R]. 1996: 1⁃100. |

| 19 | Gabi software [EB/OL]. [2020⁃11⁃16]. . |

| 20 | Balance table of electricity in 2017[EB/OL]. [2020⁃11⁃16]. . |

| 21 | XU X, JAYARAMAN K, MORIN C, et al. Life cycle assessment of wood⁃fibre⁃reinforced polypropylene composites [J]. Journal of Materials Processing Technology, 2008, 198(1):168⁃177. |

| 22 | FROUNCHI M, MEHRABZADEH M, PARVARY M. Toughening epoxy resins with solid acrylonitrile⁃butadiene rubber [J]. Polymer International, 2015, 49(2):163⁃177. |

| 23 | WILSON J B. Life⁃cycle inventory of formaldehyde⁃based resins used in wood composites in terms of resources, emissions, energy and carbon [J]. Wood & Fiber Science, 2010, 42: 125⁃143. |

| 24 | NGUYEN T H T, YASUNORI K, HIROKAZU S, et al. Techno⁃economic and environmental assessment of bioethanol⁃based chemical process: a case study on ethyl acetate [J]. Environmental Progress & Sustainable Energy, 2010, 30(4): 675⁃684. |

| 25 | KIM S, OVERCASH M. Energy in chemical manufacturing processes: gate‐to‐gate information for life cycle assessment [J]. Journal of Chemical Technology & Biotechnology, 2003, 78(9): 995⁃1 005. |

| 26 | JONKERS N, KROP H, VAN E H, et al. Life cycle assessment of flame retardants in an electronics application [J]. The International Journal of Life Cycle Assessment, 2016, 21(2): 146⁃161. |

| 27 | HOWE S, KOLIOS A J, BRENNAN F P. Environmental life cycle assessment of commercial passenger jet airliners [J]. Transportation Research Part D, 2013, 19: 34⁃41. |

| 28 | SCELSI L, BONNER M, HODZIC A, et al. Potential emissions savings of lightweight composite aircraft components evaluated through life cycle assessment [J]. eXPRESS Polymer Letters, 2011, 5(3): 209⁃217. |

| [1] | 李正典, 宋乐, 李明昊, 何雪涛, 谢鹏程, 杨卫民. 注射成型柔性制造模具系统的设计与实验研究[J]. 中国塑料, 2022, 36(7): 104-108. |

| [2] | 刘学军. 直接电加热滚塑工艺的传热分析[J]. 中国塑料, 2022, 36(7): 109-114. |

| [3] | 王晓东, 王权, 陈拓, 郑悦. 基于灰色关联分析和熵权法的双色注塑多目标参数优化[J]. 中国塑料, 2022, 36(7): 115-120. |

| [4] | 张鑫, 全淑苗. 基于中国政策的废旧农膜回收再利用现状研究[J]. 中国塑料, 2022, 36(7): 136-142. |

| [5] | 李果, 朱惠豪, 马玉录, 王玉, 吉华建, 谢林生. 导热型微孔透气薄膜的制备及性能研究[J]. 中国塑料, 2022, 36(7): 14-20. |

| [6] | 刘杨, 朱向哲. 新型偏心三螺杆挤出机流体混合特性分析[J]. 中国塑料, 2022, 36(7): 150-156. |

| [7] | 宋银宝, 杨建军, 李传敏. PDMS/SiC功能梯度复合材料性能与制造精度研究[J]. 中国塑料, 2022, 36(7): 30-36. |

| [8] | 黄雪梅, 柳和生, 黄兴元, 余忠, 江诗雨. U型件的气体辅助挤出成型工艺的数值模拟与实验研究[J]. 中国塑料, 2022, 36(7): 93-103. |

| [9] | 刘政, 刘振峰, 周国发. 双螺杆湿法制粒关键质量属性调控机理模拟研究[J]. 中国塑料, 2022, 36(6): 100-107. |

| [10] | 胥永林, 张维合, 冯国树, 宋东阳, 杜海, 王靖, 魏海涛. 智能热水壶主体复杂抽芯及随形水路注塑模设计[J]. 中国塑料, 2022, 36(6): 137-141. |

| [11] | 马占峰, 牛国强, 芦珊. 中国塑料加工业(2021)[J]. 中国塑料, 2022, 36(6): 142-148. |

| [12] | 陈轲, 刘鸣飞, 赵彪, 潘凯. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154. |

| [13] | 刘伟, 吴显, 陈小澄, 成晓琼, 张纯. 羧基化填料对聚乙烯醇/纳米纤维素水凝胶力学、导电和传感性能的影响[J]. 中国塑料, 2022, 36(6): 16-23. |

| [14] | 张庆弢, 毕超. 基于CFD⁃DEM的水下切粒装置水室内颗粒流动过程数值模拟[J]. 中国塑料, 2022, 36(6): 87-91. |

| [15] | 吴雄杰, 陶强, 朱东波, 程劲松, 储雨, 许磊. 食品接触用生物降解塑料购物袋材质鉴别与总迁移量研究[J]. 中国塑料, 2022, 36(5): 127-132. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2