京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (11): 142-152.DOI: 10.19491/j.issn.1001-9278.2025.11.022

• 综述 • 上一篇

出版日期:2025-11-26

发布日期:2025-11-21

通讯作者:

王勇 E-mail:20100428@ceic.com基金资助:

WANG Yong( ), SUN Xiaojie, WANG Rong, SUN Miaomiao

), SUN Xiaojie, WANG Rong, SUN Miaomiao

Online:2025-11-26

Published:2025-11-21

Contact:

WANG Yong

E-mail:20100428@ceic.com

摘要:

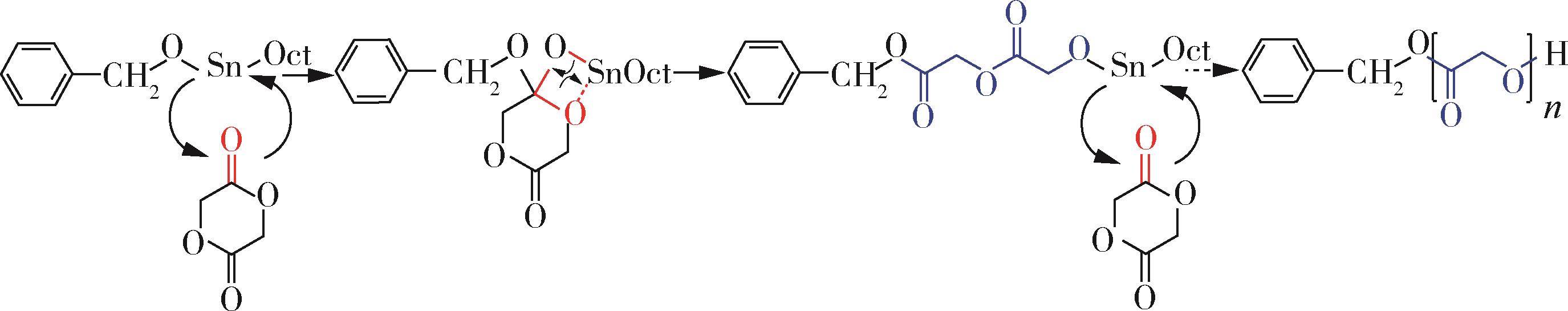

全面系统地总结了聚乙醇酸(PGA)共聚改性方面的最新研究进展,涵盖嵌段共聚和无规共聚的设计策略,以及共聚体系对材料结晶性、力学性能和降解行为的影响。此外,还探讨了PGA与其他高分子材料的共混改性研究,包括如何通过物理共混改善PGA的韧性和加工性能。

中图分类号:

王勇, 孙小杰, 王荣, 孙苗苗. 聚乙醇酸改性研究进展[J]. 中国塑料, 2025, 39(11): 142-152.

WANG Yong, SUN Xiaojie, WANG Rong, SUN Miaomiao. Advances in modification of poly(glycolic acid)[J]. China Plastics, 2025, 39(11): 142-152.

| 聚合方法 | 共聚单体 | 温度/℃ | 时间/h | 介质 | 催化剂 | 重均分子量/g·mol-1 | 参考文献 |

|---|---|---|---|---|---|---|---|

| 溶液缩聚 | 乙醇酸、癸二酸、乙二醇 | 215 | ⁃⁃ | 甲苯 | ⁃⁃ | 2 450 | [ |

| 溶液缩聚 | 乙醇酸乙酯、癸二酸二乙酯、1,4⁃丁二醇 | 60 | 95 | 二苯醚 | 南极假丝酵母脂肪酶B | 28 300 | [ |

| 熔融/固相缩聚 | 乙醇酸、L⁃乳酸 | 190、170 | 5、20 | 无 | 甲磺酸 | 80 000 | [ |

| 熔融/固相缩聚 | 乙醇酸、2⁃羟基异丁酸 | 190~230、190 | 5、20 | 无 | 二水合醋酸锌 | 24 900 | [ |

| 熔融本体缩聚 | 乙醇酸、丁二酸二甲酯、1,4⁃丁二醇 | 195~198 | 4~5 | 无 | 三氧化二锑 | 89 800 | [ |

| 聚合方法 | 共聚单体 | 温度/℃ | 时间/h | 介质 | 催化剂 | 重均分子量/g·mol-1 | 参考文献 |

|---|---|---|---|---|---|---|---|

| 溶液缩聚 | 乙醇酸、癸二酸、乙二醇 | 215 | ⁃⁃ | 甲苯 | ⁃⁃ | 2 450 | [ |

| 溶液缩聚 | 乙醇酸乙酯、癸二酸二乙酯、1,4⁃丁二醇 | 60 | 95 | 二苯醚 | 南极假丝酵母脂肪酶B | 28 300 | [ |

| 熔融/固相缩聚 | 乙醇酸、L⁃乳酸 | 190、170 | 5、20 | 无 | 甲磺酸 | 80 000 | [ |

| 熔融/固相缩聚 | 乙醇酸、2⁃羟基异丁酸 | 190~230、190 | 5、20 | 无 | 二水合醋酸锌 | 24 900 | [ |

| 熔融本体缩聚 | 乙醇酸、丁二酸二甲酯、1,4⁃丁二醇 | 195~198 | 4~5 | 无 | 三氧化二锑 | 89 800 | [ |

| [1] | KWON Diana. Three ways to solve the plastics pollution crisis [J]. Nature, 2023, 616(7956): 234⁃237. |

| [2] | JAMBECK Jenna R, GEYER Roland, WILCOX Chris, et al. Plastic waste inputs from land into the ocean [J]. Science, 2015, 347(6223): 768⁃771. |

| [3] | KOELMANS Albert A, REDONDO⁃HASSELERHARM Paula E, Nur Hazimah Mohamed NOR, et al. Risk assessment of microplastic particles [J]. Nature Reviews Materials, 2022, 7(2): 138⁃152. |

| [4] | AKDOGAN Zeynep, GUVEN Basak. Microplastics in the environment: A critical review of current understanding and identification of future research needs [J]. Environmental Pollution, 2019, 254: 24. |

| [5] | YU Renshou, SINGH Sher. Microplastic Pollution: Threats and Impacts on Global Marine Ecosystems [J]. Sustainability, 2023, 15(17): 21. |

| [6] | DERRAIK José G.B. The pollution of the marine environment by plastic debris: a review [J]. Marine Pollution Bulletin, 2002, 44(9): 842⁃852. |

| [7] | XANTHOS Dirk, WALKER Tony R. International policies to reduce plastic marine pollution from single⁃use plastics (plastic bags and microbeads): A review [J]. Marine Pollution Bulletin, 2017, 118(1⁃2): 17⁃26. |

| [8] | MURCIA VALDERRAMA Maria A., VAN PUTTEN Robert⁃Jan, GRUTER Gert⁃Jan M.. The potential of oxalic ⁃ and glycolic acid based polyesters (review). Towards CO2 as a feedstock (Carbon Capture and Utilization ⁃ CCU) [J]. European Polymer Journal, 2019, 119: 445⁃468. |

| [9] | GABIRONDO Elena, SANGRONIZ Ainara, ETXEBERRIA Agustin, et al. Poly(hydroxy acids) derived from the self⁃condensation of hydroxy acids: from polymerization to end⁃of⁃life options [J]. Polymer Chemistry, 2020, 11(30): 4 861⁃4 874. |

| [10] | YU Bor⁃Yih, CHUNG Chuan⁃Yi, Lung CHIEN I. Development of a plant⁃wide Dimethyl Oxalate (DMO) synthesis process from syngas: Rigorous design and optimization [J]. Computers & Chemical Engineering, 2018, 119: 85⁃100. |

| [11] | SAMANTARAY Paresh Kumar, LITTLE Alastair, HADDLETON David M., et al. Poly(glycolic acid) (PGA): a versatile building block expanding high performance and sustainable bioplastic applications [J]. Green Chemistry, 2020, 22(13): 4 055⁃4 081. |

| [12] | YAMANE Kazuyuki, SATO Hiroyuki, ICHIKAWA Yukio, et al. Development of an industrial production technology for high⁃molecular⁃weight polyglycolic acid [J]. Polymer Journal, 2014, 46(11): 769⁃775. |

| [13] | OLEWNIK E., CZERWIŃSKI W. Synthesis, structural study and hydrolytic degradation of copolymer based on glycolic acid and bis-2⁃hydroxyethyl terephthalate [J]. Polymer Degradation and Stability, 2009, 94(2): 221⁃226. |

| [14] | HU Han, ZHANG Ruoyu, WANG Jinggang, et al. A mild method to prepare high molecular weight poly(butylene furandicarboxylate⁃co⁃glycolate) copolyesters: effects of the glycolate content on thermal, mechanical, and barrier properties and biodegradability [J]. Green Chemistry, 2019, 21(11): 3 013⁃3 022. |

| [15] | DING Yue, HUANG Dan, AI Tianhao, et al. Bio⁃Based Poly(butylene furandicarboxylate⁃co⁃glycolate) Copolyesters: Synthesis, Properties, and Hydrolysis in Different Aquatic Environments for Water Degradation Application [J]. ACS Sustainable Chemistry & Engineering, 2021, 9(3): 1 254⁃1 263. |

| [16] | WANG Yong, LIU Jiajian, LI Chuncheng, et al. Synthesis and characterization of poly(butylene terephthalate⁃co⁃glycolic acid) biodegradable copolyesters [J]. European Polymer Journal, 2022, 180: 8. |

| [17] | JIANG Bingxue, WANG Yisong, PENG Zhengqi, et al. Synthesis of Poly(butylene adipate terephthalate)⁃co⁃poly(glycolic acid) with Enhanced Degradability in Water [J]. Macromolecules, 2023. |

| [18] | SIMITZIS J, SOULIS S, TRIANTOU D, et al. Synthesis and characterization of hydrolytically degradable copolyester biomaterials based on glycolic acid, sebacic acid and ethylene glycol [J]. Journal of Materials Science: Materials in Medicine, 2011, 22(12): 2 673⁃2 684. |

| [19] | YANG Zhe, ZHANG Xiaofang, LUO Xingen, et al. Enzymatic Synthesis of Poly(butylene⁃co⁃sebacate⁃co⁃glycolate) Copolyesters and Evaluation of the Copolymer Nanoparticles as Biodegradable Carriers for Doxorubicin Delivery [J]. Macromolecules, 2013, 46(5): 1 743⁃1 753. |

| [20] | MOON Sung⁃Il, DEGUCHI Kenji, MIYAMOTO Masatoshi, et al. Synthesis of polyglactin by melt/solid polycondensation of glycolic/L⁃lactic acids [J]. Polymer International, 2004, 53(3): 254⁃258. |

| [21] | SOCCIO Michelina, LOTTI Nadia, FINELLI Lara, et al. (2⁃Hydroxy isobutyric) acid containing poly(glycolic acid): Structure⁃properties relationship [J]. Journal of Polymer Science Part B: Polymer Physics, 2010, 48(17): 1 901⁃1 910. |

| [22] | HU Han, LI Jiayi, TIAN Ying, et al. Experimental and Theoretical Study on Glycolic Acid Provided Fast Bio/Seawater⁃Degradable Poly(Butylene Succinate⁃co⁃Glycolate) [J]. ACS Sustainable Chemistry & Engineering, 2021, 9(10): 3 843⁃3 852. |

| [23] | ATHANASIOU Kyriacos A, NIEDERAUER Gabriele G, Mauli AGRAWAL C. Sterilization, toxicity, biocompatibility and clinical applications of polylactic acid polyglycolic acid copolymers [J]. Biomaterials, 1996, 17(2): 93⁃102. |

| [24] | MURCIA VALDERRAMA Maria A, VAN PUTTEN Robert⁃Jan, GRUTER Gert⁃Jan M. PLGA Barrier Materials from CO2. The influence of Lactide Co⁃monomer on Glycolic Acid Polyesters [J]. ACS Applied Polymer Materials, 2020, 2(7): 2 706⁃2 718. |

| [25] | AYYOOB Muhammad, LEE Seungmook, KIM Young Jun. Well⁃defined high molecular weight polyglycolide⁃b⁃poly(L⁃)lactide⁃b⁃polyglycolide triblock copolymers: synthesis, characterization and microstructural analysis [J]. Journal of Polymer Research, 2020, 27(5). |

| [26] | LI Jian, ROTHSTEIN Sam N, LITTLE Steven R, et al. The Effect of Monomer Order on the Hydrolysis of Biodegradable Poly(lactic⁃co⁃glycolic acid) Repeating Sequence Copolymers [J]. Journal of the American Chemical Society, 2012, 134(39): 16 352⁃16 359. |

| [27] | DOBRZYNSKI Piotr, LI Suming, KASPERCZYK Janusz, et al. Structure-Property Relationships of Copolymers Obtained by Ring⁃Opening Polymerization of Glycolide and ε⁃Caprolactone. Part 1. Synthesis and Characterization [J]. Biomacromolecules, 2005, 6(1): 483⁃488. |

| [28] | JUNG Youngmee, LEE Sun⁃Hee, KIM Sang⁃Heon, et al. Synthesis and characterization of the biodegradable and elastic terpolymer poly(glycolide⁃co⁃L⁃lactide⁃co⁃ϵ⁃caprolactone) for mechano⁃active tissue engineering [J]. Journal of Biomaterials Science, Polymer Edition, 2012, 24(4): 386⁃397. |

| [29] | RITTINGHAUS Ruth D, ZENNER Johannes, PICH Andrij, et al. Master of Chaos and Order: Opposite Microstructures of PCL⁃co⁃PGA⁃co⁃PLA Accessible by a Single Catalyst[J]. Angewandte Chemie⁃International Edition, 2022, 61(11). |

| [30] | ZHANG Pengfei, LADELTA Viko, Edy ABOU⁃HAMAD, et al. Catalyst switch strategy enabled a single polymer with five different crystalline phases [J]. Nature communications, 2023, 14(1): 7 559. |

| [31] | WANG Yong, WEN Liang, LIU Jiajian, et al. Synthesis of biodegradable PGA⁃PBC⁃PGA triblock copolymers and closed⁃loop recycling via a thermal depolymerization strategy [J]. Green Chemistry, 2023, 25(23): 9 998⁃10 009. |

| [32] | ZURITA Raül, Jordi PUIGGALí, FRANCO Lourdes, et al. Copolymerization of glycolide and trimethylene carbonate [J]. Journal of Polymer Science Part A: Polymer Chemistry, 2006, 44(2): 993⁃1 013. |

| [33] | DAVACHI S M, KAFFASHI B, Mohammadi ROUSHANDEH J. Synthesis and characterization of a novel terpolymer based on L⁃lactide, glycolide, and trimethylene carbonate for specific medical applications [J]. Polymers for Advanced Technologies, 2012, 23(3): 565⁃573. |

| [34] | WEN Shaohua, LI Yongfei, CHEN Weixing, et al. Synthesis and properties of polylactide terpolymers P(LLA‐TMC‐GA) catalyzed by zirconium (IV) acetylacetonate [J]. Applied Organometallic Chemistry, 2017, 32(3). |

| [35] | XIAOMENG Wu, XIAOYU Chen, ZHONGYONG Fan. Totally biodegradable poly(trimethylene carbonate/glycolide⁃block⁃L⁃lactide/glycolide) copolymers: synthesis, characterization and enzyme⁃catalyzed degradation behavior [J]. European Polymer Journal, 2018, 101: 140⁃150. |

| [36] | PAN Hongwei, WANG Ye, JIA Shiling, et al. Biodegradable Poly(butylene adipate⁃co⁃terephthalate)/Poly(glycolic acid) Films: Effect of Poly(glycolic acid) Crystal on Mechanical and Barrier Properties [J]. Chinese Journal of Polymer Science, 2023, 41(7): 1 123⁃1 132. |

| [37] | WANG Kai, SHEN Jianing, MA Zhao, et al. Preparation and Properties of Poly(ethylene glycol⁃co⁃cyclohexane-1,4⁃dimethanol terephthalate)/Polyglycolic Acid (PETG/PGA) Blends [J]. Polymers, 2021, 13(3): 20. |

| [38] | LIU Deguo, XIE Qimeng, LIU Ziwei, et al. Improvement of melt viscosity and compatibility of polyglycolic acid (PGA)/polylactic acid (PLA) blend via reactive blending with bifunctional and multifunctional hybrid chain extender [J]. Journal of Applied Polymer Science, 2023: 11. |

| [39] | MA Zhirui, YIN Tian, JIANG Zhikui, et al. Bio⁃based epoxidized soybean oil branched cardanol ethers as compatibilizers of polybutylene succinate (PBS)/polyglycolic acid (PGA) blends [J]. International Journal of Biological Macromolecules, 2024, 259: 13. |

| [40] | WANG Rong, SUN Xiaojie, CHEN Lanlan, et al. Morphological and mechanical properties of biodegradable poly(glycolic acid)/poly(butylene adipate⁃co⁃terephthalate) blends with in situ compatibilization [J]. RSC Advances, 2021, 11(3): 1 241⁃1 249. |

| [41] | 孙苗苗, 尹 甜, 蒋志魁, 等. PBAT/PGA共混材料制备及其发泡行为研究[J]. 塑料科技, 2022, 50(12): 59⁃62. |

| [42] | 江 猛, 刘胜峰, 孙小杰, 等. PGA/PBAT复合材料抗水解性能研究[J]. 塑料科技, 2022, 50(07): 32⁃37. |

| [43] | SHEN Jianing, WANG Kai, MA Zhao, et al. Biodegradable blends of poly(butylene adipate⁃co⁃terephthalate) and polyglycolic acid with enhanced mechanical, rheological and barrier performances [J]. Journal of Applied Polymer Science, 2021, 138(43): 15. |

| [44] | NIU Deyu, LI Jiaxuan, XU Pengwu, et al. High⁃performance and durable fibrous poly(glycolic acid)/poly(butylene adipate⁃co⁃terephthalate) blends by reactive compatibilization and solid⁃state drawing [J]. Polymer Degradation and Stability, 2023, 210: 9. |

| [45] | SAMANTARAY Paresh Kumar, ELLINGFORD Christopher, FARRIS Stefano, et al. Electron Beam⁃Mediated Cross⁃Linking of Blown Film⁃Extruded Biodegradable PGA/PBAT Blends toward High Toughness and Low Oxygen Permeation [J]. ACS Sustainable Chemistry & Engineering, 2022, 10(3): 1 267⁃1 276. |

| [46] | XU Pengwu, TAN Shuai, NIU Deyu, et al. Highly Toughened Sustainable Green Polyglycolic Acid/Polycaprolactone Blends with Balanced Strength: Morphology Evolution, Interfacial Compatibilization, and Mechanism [J]. ACS Applied Polymer Materials, 2022, 4(8): 5 772⁃5 780. |

| [47] | WU Han, WANG Chunyu, NING Zhenbo, et al. Ultra⁃toughened poly(glycolic acid)⁃based blends with controllable hydrolysis behavior fabricated via reactive compatibilization [J]. European Polymer Journal, 2022, 181: 11. |

| [48] | 孙苗苗, 孙小杰, 王 荣, 等. PBS增韧改性PGA共混物的制备及性能[J]. 塑料科技, 2022, 50(03): 5⁃8. |

| [49] | 孙苗苗, 孙小杰, 王 荣, 等. 扩链剂对PGA/PBS共混体系结构及性能的影响[J]. 塑料科技, 2022, 50(04): 5⁃9. |

| [50] | LIU Deguo, XIE Qimeng, LIU Ziwei, et al. Improvement of melt viscosity and compatibility of polyglycolic acid (PGA)/polylactic acid (PLA) blend via reactive blending with bifunctional and multifunctional hybrid chain extender [J]. Journal of Applied Polymer Science, 2023, 140(40): 11. |

| [51] | SHEN Hong, HU Xixue, YANG Fei, et al. Cell affinity for bFGF immobilized heparin⁃containing poly(lactide⁃co⁃glycolide) scaffolds [J]. Biomaterials, 2011, 32(13): 3 404⁃3 412. |

| [52] | SONG Jibin, YANG Xiangyu, JACOBSON Orit, et al. Ultrasmall Gold Nanorod Vesicles with Enhanced Tumor Accumulation and Fast Excretion from the Body for Cancer Therapy [J]. Advanced Materials, 2015, 27(33): 4 910⁃4 917. |

| [53] | FERNáNDEZ⁃Carballido A, PASTORIZA P, BARCIA E, et al. PLGA/PEG⁃derivative polymeric matrix for drug delivery system applications: Characterization and cell viability studies [J]. International Journal of Pharmaceutics, 2008, 352(1/2): 50⁃57. |

| [54] | 孙颖,白林,刘明昊,等.生物聚酯保鲜膜的制备及其保鲜效果比较[J].中国塑料,2023,37(10):93⁃100. |

| [1] | 郑世伦, 周启伟, 刘斌, 梁旭之, 袁明园. 超支化聚酯改性碳纳米管/水性不饱和聚酯复合材料的结构与性能研究[J]. 中国塑料, 2025, 39(9): 63-67. |

| [2] | 涂著, 马会霞, 李澜鹏, 周峰, 魏志勇. 可海水降解聚酯塑料的研究进展[J]. 中国塑料, 2025, 39(6): 118-125. |

| [3] | 冯硕, 周舒毅, 焦洋, 胡淼, 张若轩, 靳玉娟. 端环氧型超支化聚酯对聚乳酸/滑石粉复合材料性能的影响研究[J]. 中国塑料, 2025, 39(5): 36-42. |

| [4] | 谢瑛鸾, 周炳, 王洪学. 包装材料及储存条件对PGA性能的影响研究[J]. 中国塑料, 2025, 39(4): 20-24. |

| [5] | 张丽平, 谢同, 高永平. 生物可降解塑料行业发展现状、存在问题与建议[J]. 中国塑料, 2025, 39(4): 75-83. |

| [6] | 文麒霖, 贾雪华, 孙炎君, 牛思霁, 陈英红, 陈宁. 生物可降解塑料包装薄膜的制备及应用进展[J]. 中国塑料, 2024, 38(9): 112-122. |

| [7] | 崔豹, 杨建军, 吴庆云, 吴明元, 张建安, 刘久逸. 聚乳酸复合材料共混改性研究及应用进展[J]. 中国塑料, 2024, 38(9): 129-136. |

| [8] | 王兴国, 吕明福, 黄逸伦, 郭鹏, 高达利, 张师军. 聚乙醇酸高温降解性能研究及其调控方法[J]. 中国塑料, 2024, 38(8): 13-19. |

| [9] | 朱光泽, 夏志东, 周炜, 王晓露, 吴玉锋, 郭福. 聚酯漆包线漆与其热解产物的共热解行为研究[J]. 中国塑料, 2024, 38(8): 53-61. |

| [10] | 何和智, 黄宗海, 赖文, 熊华威. PLA/PBAT/CB防静电包装材料的制备及其性能研究[J]. 中国塑料, 2024, 38(7): 1-8. |

| [11] | 王珅, 刘宣伯, 张艳芳, 贾雪飞, 祝桂香, 张龙贵. 生物可降解无纺布材料研究进展[J]. 中国塑料, 2024, 38(7): 86-92. |

| [12] | 骆佳伟, 周炳, 王洪学, 贾钦. 扩链条件对聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯/滑石粉共混物性能的影响[J]. 中国塑料, 2024, 38(6): 1-11. |

| [13] | 牛荷, 吕明福, 张宗胤, 徐耀辉, 许巍, 张师军, 郭鹏. 聚乙醇酸加工技术中助剂的应用进展[J]. 中国塑料, 2024, 38(6): 105-110. |

| [14] | 苏羽航, 周宇鸿, 林渊智, 毛健全, 王永祥, 刘向, 余立, 柯俊沐. 弹性体对PP/EVA无胶复合膜性能影响研究[J]. 中国塑料, 2024, 38(6): 44-50. |

| [15] | 张成, 谢继凯, 郭家杏, 郝智, 罗筑, 陈禹霖. 聚四氟乙烯改性研究进展[J]. 中国塑料, 2024, 38(11): 137-143. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2