京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2022, Vol. 36 ›› Issue (12): 142-154.DOI: 10.19491/j.issn.1001-9278.2022.12.020

• Review • Previous Articles Next Articles

CAO Ning1, LI Kai1, WANG Zhiyan2, LI Jianhua2( ), WANG Yatao2, CHEN Xi2, JIA Weiyi2, LIU Yang1(

), WANG Yatao2, CHEN Xi2, JIA Weiyi2, LIU Yang1( ), WANG Xiaodong3, LIAN Huiqin1, CUI Xiuguo1

), WANG Xiaodong3, LIAN Huiqin1, CUI Xiuguo1

Received:2022-09-27

Online:2022-12-26

Published:2022-12-20

CLC Number:

CAO Ning, LI Kai, WANG Zhiyan, LI Jianhua, WANG Yatao, CHEN Xi, JIA Weiyi, LIU Yang, WANG Xiaodong, LIAN Huiqin, CUI Xiuguo. Progress in proton⁃exchange nanocomposite films for alcohol⁃resistant fuel cells[J]. China Plastics, 2022, 36(12): 142-154.

| 质子交换膜 | 质子电导率/S·cm-1 | 甲醇渗透率/×10-7·cm2·s-1 | 吸水率/% | 离子交换容量/meq·g-1 | 拉伸强度/MPa |

|---|---|---|---|---|---|

| SPES/SiO2[ | 0.04(100 ℃) | 1.06 | 27.75 | - | - |

| SPEEK/SiO2⁃SiWA[ | 0.069 6 | 6.55 | - | - | - |

| SPSF/Nano⁃ZrO2[ | 0.077(30 ℃) | 11 | 72.0(30 ℃) | - | - |

| SPSF/Nano⁃TiO2[ | 0.072(30 ℃) | 11 | 71.6(30 ℃) | - | - |

| SPEEK/s⁃Fu[ | 0.0646(30 ℃) 0.0826(60 ℃) | 1.73(30 ℃) 2.23(60 ℃) | - | 1.68 | 14.2 |

| BSPAEKS/ s⁃Fu [ | 0.332(80 ℃) | 7.5 | 45.2(25 ℃) 52.7(80 ℃) | 1.81 | 14.4 |

| SPEEK/sul⁃MIL101(Cr)[ | 0.075(30 ℃) 0.22(75 ℃) | 7.38 | 30.8 | - | - |

| SPSF/AA⁃MOF[ | 0.212(80 ℃) | 5.8 | 16.7(20 ℃) 24.9(80 ℃) | - | - |

| SPEEK/sCNTs[ | 0.043 1 | 1.689 | 43.85 | 2.19 | 54.59 |

| SPEEK/SiO2⁃CNTs[ | 0.051 9 | 0.422 | - | - | - |

| Nafion/PVDF nanofibers[ | 0.073(20 ℃) | 14.8 | - | - | - |

| Nafion/PAN⁃ZrO2 nanofibers[ | 1.84 | 0.55 | 35(30 ℃) 40(60 ℃) 49(80 ℃) | 1.4 | - |

| SPEN/SGO/NGO[ | 0.064 | 1.43 | 50.5(80 ℃) | 1.67 | 62.02 |

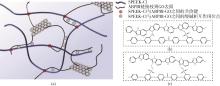

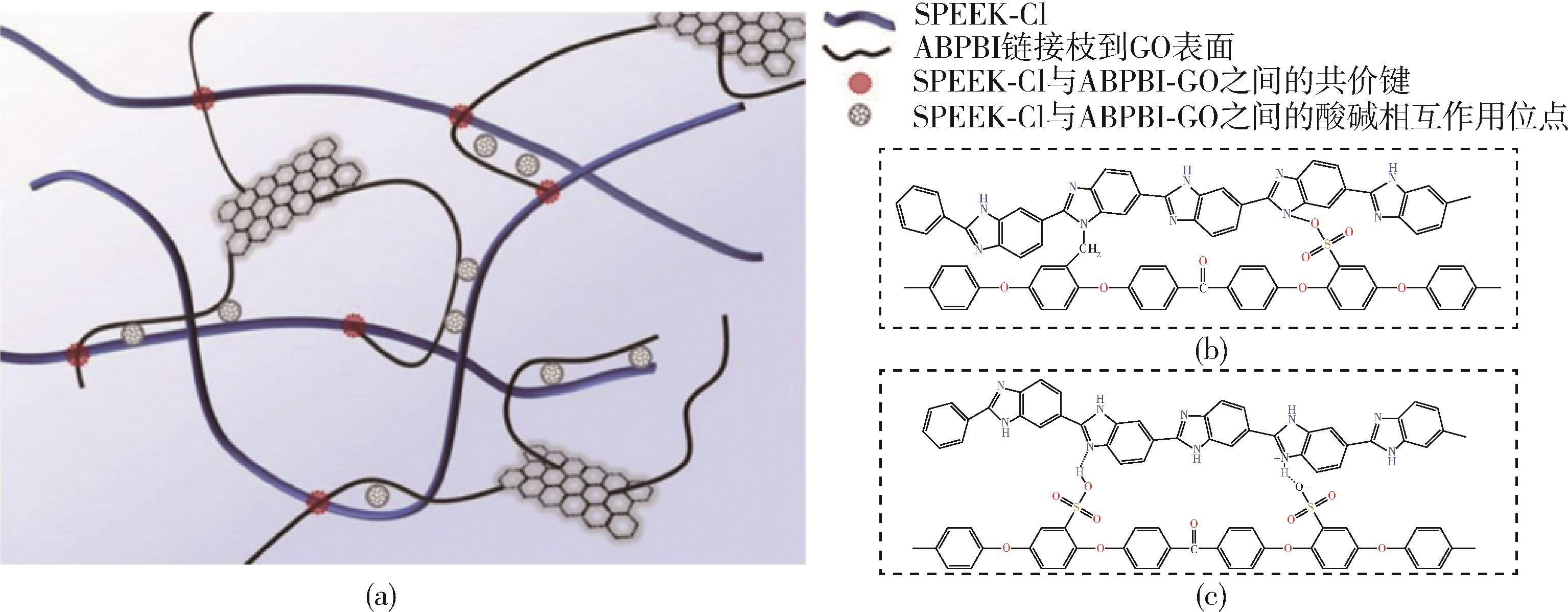

| C⁃SPEEK/ABPBI⁃GO[ | 0.185 3 | 12 | 40.3(60 ℃) | 1.96(25 ℃) | 133.6 |

| CS/E⁃MoS2[ | 0.003 6(80 ℃) | 0.328 | 25.7 | 0.51 | 74 |

| SPEEK/clay⁃SO3H[ | 0.059 5(25 ℃) 0.132(80 ℃) | 9.64 | 39.14(25 ℃) 52.78(80 ℃) | - | 43.3 |

| Nafion/CS⁃CNTs[ | 0.104 | 2.03(25 ℃) | 37.1 | 0.91 | - |

| PES/γ⁃Fe2O3[ | 0.145 | - | 28.1 | 1.59 | - |

| SPES/S⁃MoS2[ | 6.22(80 ℃) | 0.305 | 25.1(80 ℃) | 2.98 | 50.3 |

| 质子交换膜 | 质子电导率/S·cm-1 | 甲醇渗透率/×10-7·cm2·s-1 | 吸水率/% | 离子交换容量/meq·g-1 | 拉伸强度/MPa |

|---|---|---|---|---|---|

| SPES/SiO2[ | 0.04(100 ℃) | 1.06 | 27.75 | - | - |

| SPEEK/SiO2⁃SiWA[ | 0.069 6 | 6.55 | - | - | - |

| SPSF/Nano⁃ZrO2[ | 0.077(30 ℃) | 11 | 72.0(30 ℃) | - | - |

| SPSF/Nano⁃TiO2[ | 0.072(30 ℃) | 11 | 71.6(30 ℃) | - | - |

| SPEEK/s⁃Fu[ | 0.0646(30 ℃) 0.0826(60 ℃) | 1.73(30 ℃) 2.23(60 ℃) | - | 1.68 | 14.2 |

| BSPAEKS/ s⁃Fu [ | 0.332(80 ℃) | 7.5 | 45.2(25 ℃) 52.7(80 ℃) | 1.81 | 14.4 |

| SPEEK/sul⁃MIL101(Cr)[ | 0.075(30 ℃) 0.22(75 ℃) | 7.38 | 30.8 | - | - |

| SPSF/AA⁃MOF[ | 0.212(80 ℃) | 5.8 | 16.7(20 ℃) 24.9(80 ℃) | - | - |

| SPEEK/sCNTs[ | 0.043 1 | 1.689 | 43.85 | 2.19 | 54.59 |

| SPEEK/SiO2⁃CNTs[ | 0.051 9 | 0.422 | - | - | - |

| Nafion/PVDF nanofibers[ | 0.073(20 ℃) | 14.8 | - | - | - |

| Nafion/PAN⁃ZrO2 nanofibers[ | 1.84 | 0.55 | 35(30 ℃) 40(60 ℃) 49(80 ℃) | 1.4 | - |

| SPEN/SGO/NGO[ | 0.064 | 1.43 | 50.5(80 ℃) | 1.67 | 62.02 |

| C⁃SPEEK/ABPBI⁃GO[ | 0.185 3 | 12 | 40.3(60 ℃) | 1.96(25 ℃) | 133.6 |

| CS/E⁃MoS2[ | 0.003 6(80 ℃) | 0.328 | 25.7 | 0.51 | 74 |

| SPEEK/clay⁃SO3H[ | 0.059 5(25 ℃) 0.132(80 ℃) | 9.64 | 39.14(25 ℃) 52.78(80 ℃) | - | 43.3 |

| Nafion/CS⁃CNTs[ | 0.104 | 2.03(25 ℃) | 37.1 | 0.91 | - |

| PES/γ⁃Fe2O3[ | 0.145 | - | 28.1 | 1.59 | - |

| SPES/S⁃MoS2[ | 6.22(80 ℃) | 0.305 | 25.1(80 ℃) | 2.98 | 50.3 |

| 1 | Ilbeygi H, Ghasemi M, Emadzadeh D, et al. Power generation and wastewater treatment using a novel SPEEK nanocomposite membrane in a dual chamber microbial fuel cell[J]. International Journal of Hydrogen Energy, 2015, 40(1): 477⁃487. |

| 2 | Kamarudin S K, Achmad F, Daud W R W. Overview on the application of direct methanol fuel cell (DMFC) for portable electronic devices[J]. International Journal of Hydrogen Energy, 2009, 34(16): 6 902⁃6 916. |

| 3 | Roy A, Hickner M A, Einsla B R, et al. Synthesis and characterization of partially disulfonated hydroquinone⁃based poly(arylene ether sulfone)s random copolymers for application as proton exchange membranes[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2009, 47(2): 384⁃391. |

| 4 | Felix C, Jao T⁃C, Pasupathi S, et al. Optimisation of electrophoretic deposition parameters for gas diffusion electrodes in high temperature polymer electrolyte membrane fuel cells[J]. Journal of Power Sources, 2013, 243: 40⁃47. |

| 5 | Branco C M, Sharma S, De Camargo Forte M M, et al. New approaches towards novel composite and multilayer membranes for intermediate temperature⁃polymer electrolyte fuel cells and direct methanol fuel cells[J]. Journal of Power Sources, 2016, 316: 139⁃159. |

| 6 | Neelakandan S, Kanagaraj P, Sabarathinam R M, et al. Polypyrrole layered SPEES/TPA proton exchange membrane for direct methanol fuel cells[J]. Applied Surface Science, 2015, 359: 272⁃279. |

| 7 | Gittleman C S, Kongkanand A, Masten D, et al. Materials research and development focus areas for low cost automotive proton⁃exchange membrane fuel cells[J]. Current Opinion in Electrochemistry, 2019, 18: 81⁃89. |

| 8 | Goor M, Menkin S, Peled E. High power direct methanol fuel cell for mobility and portable applications[J]. International Journal of Hydrogen Energy, 2019, 44(5): 3 138⁃3 143. |

| 9 | Lopez⁃Haro M, Guetaz L, Printemps T, et al. Three⁃dimensional analysis of Nafion layers in fuel cell electrodes[J]. Nat Commun, 2014, 5: 5 229. |

| 10 | Modestino M A, Kusoglu A, Hexemer A, et al. Controlling nafion structure and properties via wetting interactions[J]. Macromolecules, 2012, 45(11): 4 681⁃4 688. |

| 11 | Patel H A, Mansor N, Gadipelli S, et al. Superacidity in Nafion/MOF hybrid membranes retains water at low humidity to enhance proton conduction for fuel cells[J]. ACS Appl Mater Interfaces, 2016, 8(45): 30 687⁃30 691. |

| 12 | Junoh H, Jaafar J, Nordin N, et al. Performance of polymer electrolyte membrane for direct methanol fuel cell application: perspective on morphological structure[J]. Membranes (Basel), 2020, 10(3). |

| 13 | Hosseinpour M, Sahoo M, Perez⁃Page M, et al. Improving the performance of direct methanol fuel cells by implementing multilayer membranes blended with cellulose nanocrystals[J]. International Journal of Hydrogen Energy, 2019, 44(57): 30 409⁃30 419. |

| 14 | Tsai J⁃C, Lin C⁃K, Kuo J⁃F, et al. Preparation and properties of crosslinked sulphonated poly(arylene ether sulphone) blend s for direct methanol fuel cell applications[J]. Journal of Power Sources, 2010, 195(13): 4 072⁃4 079. |

| 15 | Sun X, Simonsen S C, Norby T, et al. Composite membranes for high temperature PEM fuel cells and electrolysers: a critical review[J]. Membranes (Basel), 2019, 9(7). |

| 16 | Sun P, Li Z, Wang S, et al. Performance enhancement of polybenzimidazole based high temperature proton exchange membranes with multifunctional crosslinker and highly sulfonated polyaniline[J]. Journal of Membrane Science, 2018, 549: 660⁃669. |

| 17 | Tripathi B P, Shahi V K. Organic–inorganic nanocomposite polymer electrolyte membranes for fuel cell applications[J]. Progress in Polymer Science, 2011, 36(7): 945⁃979. |

| 18 | Ahmed M, Dincer I. A review on methanol crossover in direct methanol fuel cells: challenges and achievements[J]. International Journal of Energy Research, 2011, 35(14): 1 213⁃1 228. |

| 19 | Xu M, Xue H, Wang Q, et al. Sulfonated poly(arylene ether)s based proton exchange membranes for fuel cells[J]. International Journal of Hydrogen Energy, 2021, 46(62): 31 727⁃31 753. |

| 20 | Kim D⁃J, Hwang H⁃Y, Jung S⁃B, et al. Sulfonated poly(arylene ether sulfone)/Laponite⁃SO3H composite membrane for direct methanol fuel cell[J]. Journal of Industrial and Engineering Chemistry, 2012, 18(1): 556⁃562. |

| 21 | Wang Z, Ni H, Zhao C, et al. Investigation of sulfonated poly(ether ether ketone sulfone)/heteropolyacid composite membranes for high temperature fuel cell applications[J]. Journal of Polymer Science Part B: Polymer Physics, 2006, 44(14): 1 967⁃1 978. |

| 22 | Liu K⁃L, Lee H⁃C, Wang B⁃Y, et al. Sulfonated poly(styrene⁃ block ⁃(ethylene⁃ ran ⁃butylene)⁃ block ⁃styrene (SSEBS)⁃zirconium phosphate (ZrP) composite membranes for direct methanol fuel cells[J]. Journal of Membrane Science, 2015, 495: 110⁃120. |

| 23 | Chen B, Li G, Wang L, et al. Proton conductivity and fuel cell performance of organic⁃inorganic hybrid membrane based on poly(methyl methacrylate)/silica[J]. International Journal of Hydrogen Energy, 2013, 38(19): 7 913⁃7 923. |

| 24 | Wen S, Gong C, Tsen W⁃C, et al. Sulfonated poly(ether sulfone)/silica composite membranes for direct methanol fuel cells[J]. Journal of Applied Polymer Science, 2009. |

| 25 | Yan Chia M, San Thiam H, Kong Leong L, et al. Effect of coupling agents on the transport properties of sulfonated poly (ether ether ketone) based composite membrane[J]. IOP Conference Series: Earth and Environmental Science, 2019, 268(1). |

| 26 | Neelakandan S, K N J, Kanagaraj P, et al. Effect of sulfonated graphene oxide on the performance enhancement of acid–base composite membranes for direct methanol fuel cells[J]. RSC Advances, 2016, 6(57): 51 599⁃51 608. |

| 27 | Wu H, Cao Y, Shen X, et al. Preparation and performance of different amino acids functionalized titania⁃embedded sulfonated poly (ether ether ketone) hybrid membranes for direct methanol fuel cells[J]. Journal of Membrane Science, 2014, 463: 134⁃144. |

| 28 | Li J, Zhang Y, Wang L. Preparation and characterization of sulfonated polyimide/TiO2 composite membrane for vanadium redox flow battery[J]. Journal of Solid State Electrochemistry, 2013, 18(3): 729⁃737. |

| 29 | Lee W, Gil S C, Kim H, et al. Partially sulfonated poly(arylene ether sulfone)/organically modified metal oxide nanoparticle composite membranes for proton exchange membrane for direct methanol fuel cell[J]. Composites Science and Technology, 2016, 129: 101⁃107. |

| 30 | Rambabu G, Bhat S D. Sulfonated fullerene in SPEEK matrix and its impact on the membrane electrolyte properties in direct methanol fuel cells[J]. Electrochimica Acta, 2015, 176: 657⁃669. |

| 31 | Neelakandan S, Liu D, Wang L, et al. Highly branched poly(arylene ether)/surface functionalized fullerene‐based composite membrane electrolyte for DMFC applications[J]. International Journal of Energy Research, 2019, 43(8): 3 756⁃3 767. |

| 32 | Li Z, He G, Zhao Y, et al. Enhanced proton conductivity of proton exchange membranes by incorporating sulfonated metal⁃organic frameworks[J]. Journal of Power Sources, 2014, 262: 372⁃379. |

| 33 | Sun H, Tang B, Wu P. Two⁃dimensional zeolitic imidazolate framework/carbon nanotube hybrid networks modified proton exchange membranes for improving transport properties[J]. ACS Appl Mater Interfaces, 2017, 9(40): 35 075⁃35 085. |

| 34 | Wang S, Luo H, Li X, et al. Amino acid⁃functionalized metal organic framework with excellent proton conductivity for proton exchange membranes[J]. International Journal of Hydrogen Energy, 2021, 46(1): 1 163⁃1 173. |

| 35 | Gahlot S, Kulshrestha V. Dramatic improvement in water retention and proton conductivity in electrically aligned functionalized CNT/SPEEK nanohybrid PEM[J]. ACS Appl Mater Interfaces, 2015, 7(1): 264⁃272. |

| 36 | Cui L, Geng Q, Gong C, et al. Novel sulfonated poly (ether ether ketone)/silica coated carbon nanotubes high⁃performance composite membranes for direct methanol fuel cell[J]. Polymers for Advanced Technologies, 2015, 26(5): 457⁃464. |

| 37 | Ranjani M, Yoo D J, Gnana Kumar G. Sulfonated Fe3O4@SiO2 nanorods incorporated sPVdF nanocomposite membranes for DMFC applications[J]. Journal of Membrane Science, 2018, 555: 497⁃506. |

| 38 | Joo S H, Pak C, Kim E A, et al. Functionalized carbon nanotube⁃poly(arylene sulfone) composite membranes for direct methanol fuel cells with enhanced performance[J]. Journal of Power Sources, 2008, 180(1): 63⁃70. |

| 39 | Li Y, Hui J, Kawchuk J, et al. Composite membranes of PVDF nanofibers impregnated with Nafion for increased fuel concentrations in direct methanol fuel cells[J]. Fuel Cells, 2019, 19(1): 43⁃50. |

| 40 | Sigwadi R, Mokrani T, Dhlamini S, et al. Nafion® reinforced with polyacrylonitrile/ZrO2 nanofibers for direct methanol fuel cell application[J]. Journal of Applied Polymer Science, 2020, 138(10). |

| 41 | Huang Y, Cheng T, Zhang X, et al. Novel composite proton exchange membrane with long⁃range proton transfer channels constructed by synergistic effect between acid and base functionalized graphene oxide[J]. Polymer, 2018, 149: 305⁃315. |

| 42 | Han J, Kim K, Kim S, et al. Cross⁃linked sulfonated poly(ether ether ketone) membranes formed by poly(2,5⁃benzimidazole)⁃grafted graphene oxide as a novel cross⁃linker for direct methanol fuel cell applications[J]. Journal of Power Sources, 2020, 448. |

| 43 | Feng K, Tang B, Wu P. Selective growth of MoS2 for proton exchange membranes with extremely high selectivity[J]. ACS Appl Mater Interfaces, 2013, 5(24): 13 042⁃13 049. |

| 44 | Divya K, Rana D, Alwarappan S, et al. Investigating the usefulness of chitosan based proton exchange membranes tailored with exfoliated molybdenum disulfide nanosheets for clean energy applications[J]. Carbohydr Polym, 2019, 208: 504⁃512. |

| 45 | Fu T, Cui Z, Zhong S, et al. Sulfonated poly(ether ether ketone)/clay⁃SO3H hybrid proton exchange membranes for direct methanol fuel cells[J]. Journal of Power Sources, 2008, 185(1): 32⁃39. |

| 46 | Narayanaswamy Venkatesan P, Dharmalingam S. Characterization and performance study of phase inversed sulfonated poly ether ether ketone – silico tungstic composite membrane as an electrolyte for microbial fuel cell applications[J]. Renewable Energy, 2017, 102: 77⁃86. |

| 47 | Mohtar S S, Ismail A F, Matsuura T. Preparation and characterization of SPEEK/MMT⁃STA composite membrane for DMFC application[J]. Journal of Membrane Science, 2011, 371(1/2): 10⁃19. |

| 48 | Chen C⁃C, Tsi H⁃Y, Tsen W⁃C, et al. PWA/silica doped sulfonated poly(ether sulfone) composite membranes for direct methanol fuel cells[J]. Journal of Applied Polymer Science, 2012, 123(2): 1 184⁃1 192. |

| 49 | Chia M Y, Thiam H S, Leong L K, et al. Effect of filler content on transport properties of sulfonated polyether ether ketone (SPEEK) composite proton exchange membranes[J]. IOP Conference Series: Materials Science and Engineering, 2018, 409. |

| 50 | Silva V S, Ruffmann B, Silva H, et al. Proton electrolyte membrane properties and direct methanol fuel cell performance[J]. Journal of Power Sources, 2005, 140(1): 34⁃40. |

| 51 | Laberty⁃Robert C, Valle K, Pereira F, et al. Design and properties of functional hybrid organic⁃inorganic membranes for fuel cells[J]. Chem Soc Rev, 2011, 40(2): 961⁃1 005. |

| 52 | Lee D C, Yang H N, Park S H, et al. Self⁃humidifying Pt–graphene/SiO2 composite membrane for polymer electrolyte membrane fuel cell[J]. Journal of Membrane Science, 2015, 474: 254⁃262. |

| 53 | Tasaki K, Gasa J, Wang H, et al. Fabrication and characterization of fullerene–Nafion composite membranes[J]. Polymer, 2007, 48(15): 4 438⁃4 448. |

| 54 | Chen H, Han S⁃Y, Liu R⁃H, et al. High conductive, long⁃term durable, anhydrous proton conductive solid⁃state electrolyte based on a metal⁃organic framework impregnated with binary ionic liquids: synthesis, characteristic and effect of anion[J]. Journal of Power Sources, 2018, 376: 168⁃176. |

| 55 | Yang F, Huang H, Wang X, et al. Proton conductivities in functionalized UiO-66: tuned properties, thermogravimetry mass, and molecular simulation analyses[J]. Crystal Growth & Design, 2015, 15(12): 5 827⁃5 833. |

| 56 | Ramaswamy P, Wong N E, Shimizu G K. MOFs as proton conductors⁃challenges and opportunities[J]. Chem Soc Rev, 2014, 43(16): 5 913⁃5 932. |

| 57 | Liang X, Zhang F, Feng W, et al. From metal–organic framework (MOF) to MOF–polymer composite membrane: enhancement of low⁃humidity proton conductivity[J]. Chem Sci, 2013, 4(3): 983⁃992. |

| 58 | Furukawa H, Cordova K E, O'keeffe M, et al. The chemistry and applications of metal⁃organic frameworks[J]. Science, 2013, 341(6149): 1230444. |

| 59 | Zhang X⁃H, Tang Q⁃Q, Yang D, et al. Preparation of poly(p⁃styrenesulfonic acid) grafted multi⁃walled carbon nanotubes and their application as a solid⁃acid catalyst[J]. Materials Chemistry and Physics, 2011, 126(1/2): 310⁃313. |

| 60 | Zhou W, Xiao J, Chen Y, et al. Sulfonated carbon nanotubes/sulfonated poly(ether sulfone ether ketone ketone) composites for polymer electrolyte membranes[J]. Polymers for Advanced Technologies, 2011, 22(12): 1 747⁃1 752. |

| 61 | Cele N P, Sinha Ray S, Pillai S K, et al. Carbon nanotubes based nafion composite membranes for fuel cell applications[J]. Fuel Cells, 2010. |

| 62 | Hasani⁃Sadrabadi M M, Dashtimoghadam E, Majedi F S, et al. Nafion/chitosan⁃wrapped CNT nanocomposite membrane for high⁃performance direct methanol fuel cells[J]. RSC Advances, 2013, 3(20). |

| 63 | Rambabu G, Bhat S D. Simultaneous tuning of methanol crossover and ionic conductivity of sPEEK membrane electrolyte by incorporation of PSSA functionalized MWCNTs: A comparative study in DMFCs[J]. Chemical Engineering Journal, 2014, 243: 517⁃525. |

| 64 | Hasanabadi N, Ghaffarian S R, Hasani⁃Sadrabadi M M. Magnetic field aligned nanocomposite proton exchange membranes based on sulfonated poly (ether sulfone) and Fe2O3 nanoparticles for direct methanol fuel cell application[J]. International Journal of Hydrogen Energy, 2011, 36(23): 15 323⁃15 332. |

| 65 | Ma C, Zhang W, Zhu Y, et al. Alignment and dispersion of functionalized carbon nanotubes in polymer composites induced by an electric field[J]. Carbon, 2008, 46(4): 706⁃710. |

| 66 | Xu X, Li L, Wang H, et al. Solution blown sulfonated poly(ether ether ketone) nanofiber–Nafion composite membranes for proton exchange membrane fuel cells[J]. RSC Advances, 2015, 5(7): 4 934⁃4 940. |

| 67 | Wang H, Li X, Zhuang X, et al. Modification of Nafion membrane with biofunctional SiO2 nanofiber for proton exchange membrane fuel cells[J]. Journal of Power Sources, 2017, 340: 201⁃209. |

| 68 | Wang H, Ma Y, Cheng B, et al. Solution blown biofunctionalized poly(vinylidene fluoride) nanofibers for application in proton exchange membrane fuel cells[J]. Electrochimica Acta, 2017, 258: 24⁃33. |

| 69 | Zizhou R E, Çay A, Akçakoca Kumbasar E P, et al. Production of poly(vinyl alcohol)/Nafion® nanofibers and their stability assessment for the use in direct methanol fuel cells[J]. Journal of Industrial Textiles, 2019, 50(6): 773⁃793. |

| 70 | Liu G, Tsen W⁃C, Jang S⁃C, et al. Mechanically robust and highly methanol⁃resistant sulfonated poly(ether ether ketone)/poly(vinylidene fluoride) nanofiber composite membranes for direct methanol fuel cells[J]. Journal of Membrane Science, 2019, 591. |

| 71 | Eda G, Chhowalla M. Chemically derived graphene oxide: towards large⁃area thin⁃film electronics and optoelectronics[J]. Adv Mater, 2010, 22(22): 2 392⁃2 415. |

| 72 | Ye Y⁃S, Tseng C⁃Y, Shen W⁃C, et al. A new graphene⁃modified protic ionic liquid⁃based composite membrane for solid polymer electrolytes[J]. Journal of Materials Chemistry, 2011, 21(28). |

| 73 | Feng K, Tang B, Wu P. "Evaporating" graphene oxide sheets (GOSs) for rolled up GOSs and its applications in proton exchange membrane fuel cell[J]. ACS Appl Mater Interfaces, 2013, 5(4): 1 481⁃1 488. |

| 74 | Karim M R, Hatakeyama K, Matsui T, et al. Graphene oxide nanosheet with high proton conductivity[J]. J Am Chem Soc, 2013, 135(22): 8 097⁃8 100. |

| 75 | Shafiei A, Oprea C, Alfantazi A, et al. In situ monitoring of the effects of hydrogen on Pb(Zr,Ti)O3 structure[J]. Journal of Applied Physics, 2011, 109(11). |

| 76 | Li J, Xu G, Cai W, et al. Non⁃destructive modification on Nafion membrane via in⁃situ inserting of sheared graphene oxide for direct methanol fuel cell applications[J]. Electrochimica Acta, 2018, 282: 362⁃368. |

| 77 | Miao S, Zhang H, Li X, et al. A morphology and property study of composite membranes based on sulfonated polyarylene ether sulfone and adequately sulfonated graphene oxide[J]. International Journal of Hydrogen Energy, 2016, 41(1): 331⁃341. |

| 78 | Zhou K, Jiang S, Bao C, et al. Preparation of poly(vinyl alcohol) nanocomposites with molybdenum disulfide (MoS2): structural characteristics and markedly enhanced properties[J]. RSC Advances, 2012, 2(31). |

| 79 | Li J, Zhang Y, Zhang S, et al. Sulfonated polyimide/s⁃MoS2 composite membrane with high proton selectivity and good stability for vanadium redox flow battery[J]. Journal of Membrane Science, 2015, 490: 179⁃189. |

| 80 | Obianigwe N, Ngene B U. Soil Stabilization for road construction: comparative analysis of a three⁃prong approach[J]. IOP Conference Series: Materials Science and Engineering, 2018, 413. |

| 81 | Choi Y S, Kim T K, Kim E A, et al. Exfoliated sulfonated poly(arylene ether sulfone)⁃clay nanocomposites[J]. Advanced Materials, 2008, 20(12): 2 341⁃2 344. |

| 82 | Awang N, Jaafar J, Ismail A F, et al. Performance of void⁃free electrospun SPEEK/cloisite as a function of degree of dispersion state on nanocomposite proton exchange membrane for direct methanol fuel cell application[J]. Membranes (Basel), 2019, 9(1). |

| 83 | Charradi K, Ahmed Z, Aranda P, et al. Silica/montmorillonite nanoarchitectures and layered double hydroxide⁃SPEEK based composite membranes for fuel cells applications[J]. Applied Clay Science, 2019, 174: 77⁃85. |

| 84 | Divya K, Rana D, Saraswathi M, et al. Investigation of the versatility of SPES membranes customized with sulfonated molybdenum disulfide nanosheets for DMFC applications[J], 2020, 45(31). |

| 85 | 谢玉洁, 张博鑫, 徐 迪, et al. 燃料电池用新型复合质子交换膜研究进展[J]. 膜科学与技术[J], 2021, 41(04): 177⁃186. |

| XIE Y J, ZHANG B X, XU D, et al. Progress in novel composite proton exchange membrane for fuel cells[J]. Membrane Science and Technology, 2021, 41(04): 177⁃186. |

| [1] | JIA Mingyin, DONG Xianwen, WANG Jiaming, CHEN Ke. Effect of impregnation method on vacuum bag press molding process and properties of polyamide 6 composites [J]. China Plastics, 2022, 36(9): 1-6. |

| [2] | ZHANG Lin, XIA Zhangchuan, HE Yadong, XIN Chunling, WANG Ruixue, REN Feng. Influence of gas flow of plasma jet carrier on modification effect for glass fiber [J]. China Plastics, 2022, 36(9): 7-15. |

| [3] | JIAO Zhiwei, WANG Kechen, ZHANG Yang, YANG Weimin. Performance of PVC/ABS composites filled with carbon black and talc powders based on carbon nano coating deposition [J]. China Plastics, 2022, 36(8): 10-15. |

| [4] | TANG Xiaoming, CAO Ning, JIANG Yuehang, WANG Qian, WANG Zhiyan, LI Jianhua, WANG Yatao, LIAN Huiqin, WANG Xiaodong, CUI Xiuguo. Research progress in polysulfone for proton⁃exchange membrane fuel cell [J]. China Plastics, 2022, 36(8): 146-158. |

| [5] | YU Jiuyang, WANG Zhonghao, CHEN Qi, XIA Yazhong. Study on properties of advanced resin matrix composites for valve body manufacturing [J]. China Plastics, 2022, 36(8): 16-22. |

| [6] | ZHANG Taozhong, CHEN Xiaolong, HAO Xiaoyu, YU Fujia. Comparison of mechanical properties and interfacial interactions of polypropylene composites filled with talc, calcium carbonate, and barium sulfate [J]. China Plastics, 2022, 36(8): 36-41. |

| [7] | QU Yuting, WANG Limei, QI Bin. Effect of poly(ethylene glycol) on properties of poly(lactic acid)/starch nanocrystal composites [J]. China Plastics, 2022, 36(8): 56-61. |

| [8] | WANG Qian, YANG Kangning, ZHAI Shaoxiong, YIN Likun, HE Shaojian, LIN Jun. Preparation and properties of composite proton exchange membranes with high proton conductivity and dimensional stability [J]. China Plastics, 2022, 36(8): 62-68. |

| [9] | SONG Yinbao, YANG Jianjun, LI Chuanmin. Study on properties and manufacturing precision of PDMS/SiC functionally gradient composites [J]. China Plastics, 2022, 36(7): 30-36. |

| [10] | YANG Xiaolong, CHEN Wenjing, LI Yongqing, YAN Xiaokun, WANG Xiulei, XIE Pengcheng, MA Xiuqing. Research progress in polymer/graphene conductive composites [J]. China Plastics, 2022, 36(6): 165-173. |

| [11] | WANG Ke, LONG Chunguang. Mechanical and tribological properties of ultra⁃high molecular weight polyethylene/sepiolite fiber composites [J]. China Plastics, 2022, 36(5): 19-23. |

| [12] | CHEN Sheng, LIANG Yingchao, WU Fangjuan, FANG Hui, FAN Xinfeng, CHEN Hui, WANG Yonggang. Preparation and interfacial modification of polyamide 6/bidirectional warp⁃knitted glass fiber composites [J]. China Plastics, 2022, 36(5): 24-28. |

| [13] | LIU Wen, SHI Wenzhao, LIU Jinshu, LU Shaofeng, ZHOU Hongjuan. Research progress in electro⁃active shape memory composite materials [J]. China Plastics, 2022, 36(4): 175-189. |

| [14] | RUAN Fangtao, XIA Chenglong, ZHANG Baogen, CAO Ye, LIU Zhi, XU Zhenzhen, ZHANG Jincao. Axial compressive properties of aramid⁃coated carbon⁃fiber⁃reinforced epoxy resins [J]. China Plastics, 2022, 36(4): 19-23. |

| [15] | PENG Bo, XIAO Yunbin, GU Jiabao, CHEN Zijun, TANG Yanhuang, ZHU Gang, XU Huanxiang. Research progress in preparation and properties of polymer/graphene composites [J]. China Plastics, 2022, 36(4): 190-197. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||