京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2023, Vol. 37 ›› Issue (11): 101-116.DOI: 10.19491/j.issn.1001-9278.2023.11.012

朱光泽1( ), 周炜1, 夏志东1(

), 周炜1, 夏志东1( ), 王晓露1, 李炳毅1, 郭福1, 吴玉锋1,2

), 王晓露1, 李炳毅1, 郭福1, 吴玉锋1,2

收稿日期:2023-05-23

出版日期:2023-11-26

发布日期:2023-11-22

通讯作者:

夏志东(1967—),女,教授,从事资源循环研究,xiazhd@bjut.edu.cn作者简介:朱光泽(1999—),男,硕士研究生,从事资源循环研究,zhuguangzebjut@163.com

基金资助:

ZHU Guangze1( ), ZHOU Wei1, XIA Zhidong1(

), ZHOU Wei1, XIA Zhidong1( ), WANG Xiaolu1, LI Bingyi1, GUO Fu1, WU Yufeng1,2

), WANG Xiaolu1, LI Bingyi1, GUO Fu1, WU Yufeng1,2

Received:2023-05-23

Online:2023-11-26

Published:2023-11-22

Contact:

XIA Zhidong

E-mail:zhuguangzebjut@163.com;xiazhd@bjut.edu.cn

摘要:

综述了有机废弃物热解过程中主要应用的分析方法,首先介绍热分析法的种类和影响因素,重点归纳了热重分析法的应用,明确了升温速率、热解气氛、驻留温度和驻留时间等是影响热解的重要因素;其次对热解动力学和热解热力学进行总结,对比了无模型法(FWO、KAS、Starink法)和有模型法(C⁃R法);然后对热重⁃傅里叶红外联用分析(TG⁃FTIR)、热重⁃质谱联用分析(TG⁃MS)、热解⁃质谱色谱联用分析(Py⁃GC/MS) 3种热解气体逸出分析方法进行对比总结;最后从工业生产、研究热解机理和热解产物控制的角度提出目前有机废弃物热解分析技术的问题以及对未来热解技术发展的展望。

中图分类号:

朱光泽, 周炜, 夏志东, 王晓露, 李炳毅, 郭福, 吴玉锋. 有机废弃物热解分析技术现状与展望[J]. 中国塑料, 2023, 37(11): 101-116.

ZHU Guangze, ZHOU Wei, XIA Zhidong, WANG Xiaolu, LI Bingyi, GUO Fu, WU Yufeng. Current situation and prospect of pyrolysis analysis technology of organic wastes[J]. China Plastics, 2023, 37(11): 101-116.

| 名称 | 缩写 | 元素组成 | 化学结构 | 常见用途 |

|---|---|---|---|---|

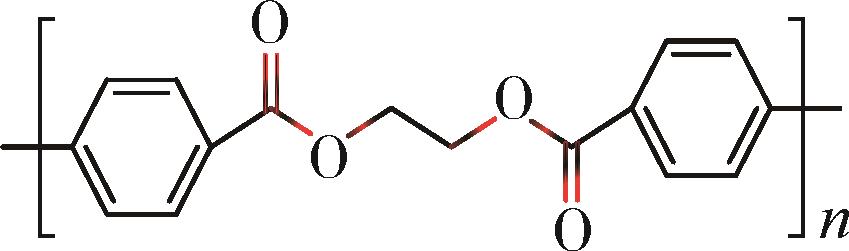

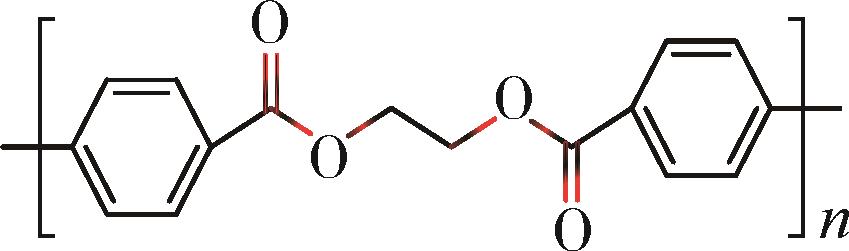

| 聚对苯二甲酸乙二醇酯 | PET | C、H、O |  | 饮料瓶等 |

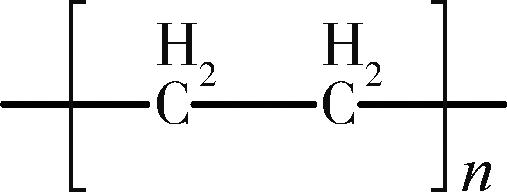

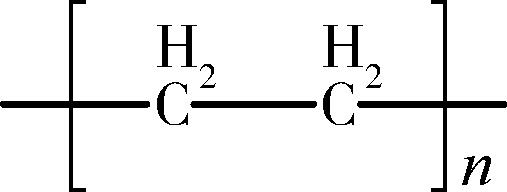

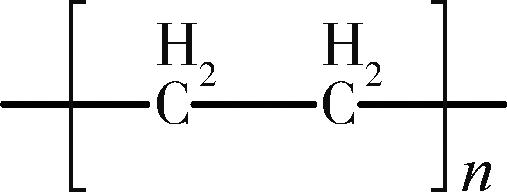

| 高密度聚乙烯 | PE⁃HD | C、H |  | 塑料袋、清洁用品等 |

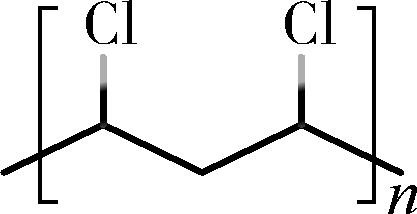

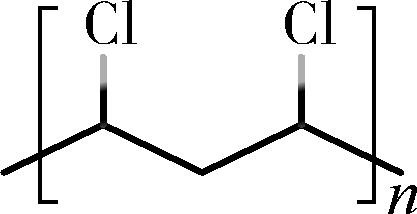

| 聚氯乙烯 | PVC | C、H、Cl |  | 雨衣、塑料膜等 |

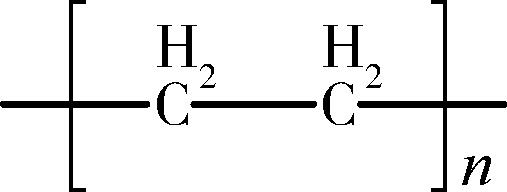

| 低密度聚乙烯 | PE⁃LD | C、H |  | 保鲜膜、塑料膜等 |

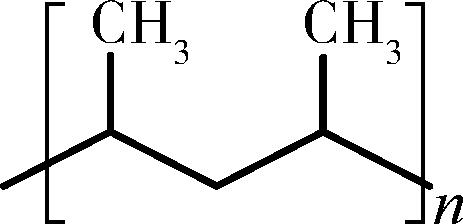

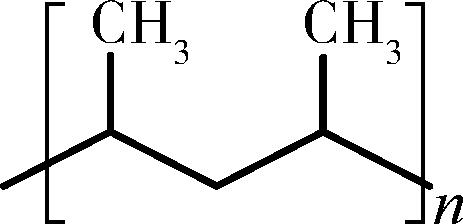

| 聚丙烯 | PP | C、H |  | 餐盒等 |

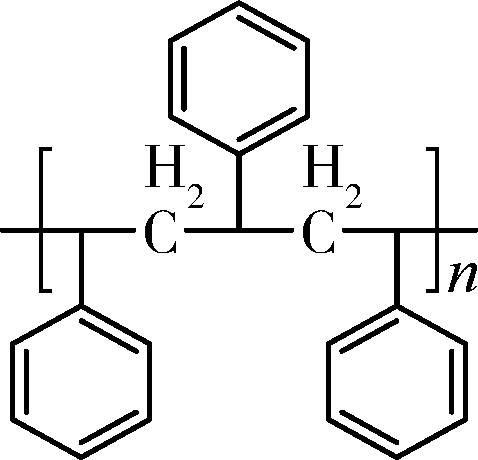

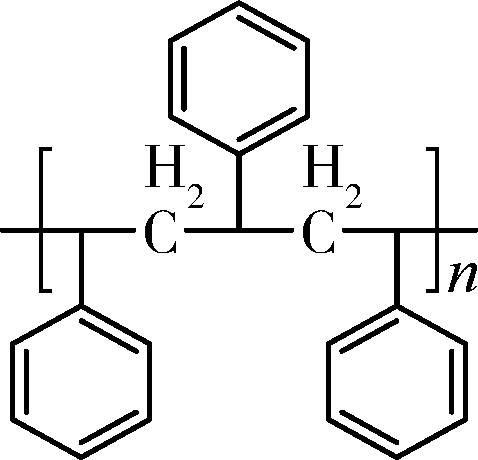

| 聚苯乙烯 | PS | C、H |  | 泡面盒、餐盒等 |

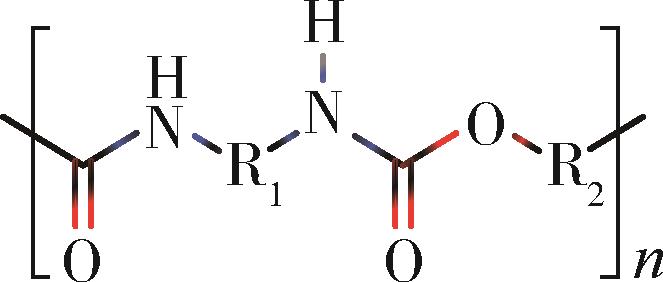

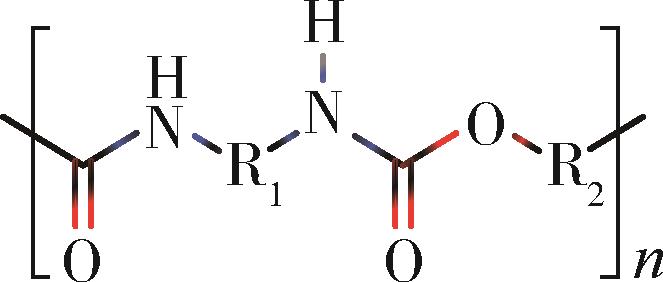

| 聚氨酯类 | PU | C、H、O、N |  | 保温材料、实心轮胎等 |

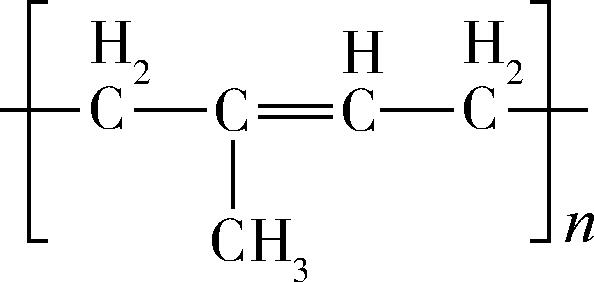

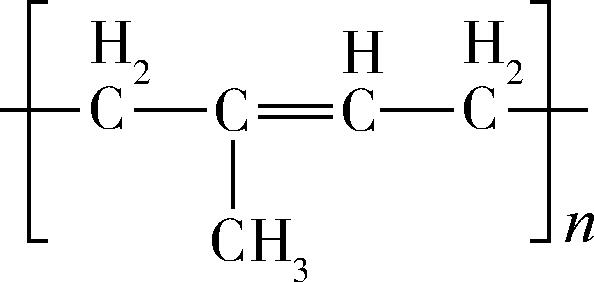

| 天然橡胶(以顺⁃1,4⁃聚异戊二烯为主要成分的天然高分子化合物) | NR | C、H |  | 轮胎、密封装备、防震装备等 |

| 名称 | 缩写 | 元素组成 | 化学结构 | 常见用途 |

|---|---|---|---|---|

| 聚对苯二甲酸乙二醇酯 | PET | C、H、O |  | 饮料瓶等 |

| 高密度聚乙烯 | PE⁃HD | C、H |  | 塑料袋、清洁用品等 |

| 聚氯乙烯 | PVC | C、H、Cl |  | 雨衣、塑料膜等 |

| 低密度聚乙烯 | PE⁃LD | C、H |  | 保鲜膜、塑料膜等 |

| 聚丙烯 | PP | C、H |  | 餐盒等 |

| 聚苯乙烯 | PS | C、H |  | 泡面盒、餐盒等 |

| 聚氨酯类 | PU | C、H、O、N |  | 保温材料、实心轮胎等 |

| 天然橡胶(以顺⁃1,4⁃聚异戊二烯为主要成分的天然高分子化合物) | NR | C、H |  | 轮胎、密封装备、防震装备等 |

| 方法 | 升温模式 | 特点 | 可获得信息 |

|---|---|---|---|

| 热重分析法 | 线性升温 | 结果直观稳定 | 物质相变过程、热损失率 |

| 传统差示扫描量热法 | 线性升温 | 灵敏度低、解析度低,只反映表观现象 | 吸放热、热容变化过程、物质相变过程 |

| 调制差示扫描量热法 | 平均慢速升温、瞬时交变正弦升温 | 灵敏度高、解析度高,测量准确,能够分离相互覆盖的转变 | 吸放热、热容变化过程、物质相变过程、总热流、震荡热流、可逆热流、不可逆热流等 |

| 差热分析法 | 等速升温 | 稳定 | 吸放热 |

| 方法 | 升温模式 | 特点 | 可获得信息 |

|---|---|---|---|

| 热重分析法 | 线性升温 | 结果直观稳定 | 物质相变过程、热损失率 |

| 传统差示扫描量热法 | 线性升温 | 灵敏度低、解析度低,只反映表观现象 | 吸放热、热容变化过程、物质相变过程 |

| 调制差示扫描量热法 | 平均慢速升温、瞬时交变正弦升温 | 灵敏度高、解析度高,测量准确,能够分离相互覆盖的转变 | 吸放热、热容变化过程、物质相变过程、总热流、震荡热流、可逆热流、不可逆热流等 |

| 差热分析法 | 等速升温 | 稳定 | 吸放热 |

| 作者 | 材料 | 方法 | 活化能/kJ·mol-1 | 平均活化能/ kJ·mol-1 | 文献 |

|---|---|---|---|---|---|

| MENARES Tamara | 废轮胎 | Starink | 102~177 | 153 | [ |

| Tang X J | 废橡胶(RT)轮胎 | FWO、KAS | 134~345 | 260、262 | [ |

| PUT轮胎 | Starink、FWO | 152~254 | 205 | ||

| Chen J W | 废轮胎 | FWO、KAS | 149~244 147~245 | 200 | [ |

| SINGH Gajendra | 废牛奶盒 | KAS、FWO | 134~299 | 175~178 | [ |

| Yao Z T | 废电视塑料外壳 | FWO、KAS | 166~337 | 214~218 | [ |

| DAS Pallab | PE⁃LD | FWO、KAS、Starink | 165~242 162~242 148~222 | — | [ |

| PE⁃HD | FWO、KAS、Starink | 146~242 146~241 146~240 | |||

| PP | FWO、KAS、Starink | 140~176 136~173 136~173 | |||

| PLA | FWO、KAS、Starink | 113~129 99~113 108~124 | |||

| ABOULKAS A | PP | KAS、FWO、Starink | 158~186 163~190 175~198 | 179、183、188 | [ |

| 作者 | 材料 | 方法 | 活化能/kJ·mol-1 | 平均活化能/ kJ·mol-1 | 文献 |

|---|---|---|---|---|---|

| MENARES Tamara | 废轮胎 | Starink | 102~177 | 153 | [ |

| Tang X J | 废橡胶(RT)轮胎 | FWO、KAS | 134~345 | 260、262 | [ |

| PUT轮胎 | Starink、FWO | 152~254 | 205 | ||

| Chen J W | 废轮胎 | FWO、KAS | 149~244 147~245 | 200 | [ |

| SINGH Gajendra | 废牛奶盒 | KAS、FWO | 134~299 | 175~178 | [ |

| Yao Z T | 废电视塑料外壳 | FWO、KAS | 166~337 | 214~218 | [ |

| DAS Pallab | PE⁃LD | FWO、KAS、Starink | 165~242 162~242 148~222 | — | [ |

| PE⁃HD | FWO、KAS、Starink | 146~242 146~241 146~240 | |||

| PP | FWO、KAS、Starink | 140~176 136~173 136~173 | |||

| PLA | FWO、KAS、Starink | 113~129 99~113 108~124 | |||

| ABOULKAS A | PP | KAS、FWO、Starink | 158~186 163~190 175~198 | 179、183、188 | [ |

| 反应机理 | 符号 | G(α) | |

|---|---|---|---|

| 化学反应机理 | 一步反应 | F1 | -ln(1-α) |

| 一步半反应 | F1.5 | 2[(1-α)-1/2-1] | |

| 两步反应 | F2 | (1-α)-1-1 | |

| 三步反应 | F3 | [(1-α)-2-1]/2 | |

| 扩散机理 | 一维扩散 | D1 | α2 |

| 二维扩散 | D2 | (1-α)ln(1-α)+α | |

| 三维扩散 | D3 | [1-(1-α)1/3]2 | |

| 四维扩散 | D4 | 1-(2/3)α-(1-α)2/3 | |

| 幂率 | 1/2幂定律反应 | P2 | α1/2 |

| 1/3幂定律反应 | P3 | α1/3 | |

| 指数定律反应 | P4 | α1/4 | |

| 相界面反应机理 | 一维反应 | R1 | α |

| 二维反应 | R2 | 1-(1-α)1/2 | |

| 三维反应 | R3 | 1-(1-α)1/3 | |

| 随机成核与生长反应机理 | 成核生长(n=1.5) | A1.5 | [-ln(1-α)]2/3 |

| 成核生长(n=2) | A2 | [-ln(1-α)]1/2 | |

| 成核生长(n=3) | A3 | [-ln(1-α)]1/3 | |

| 成核生长(n=4) | A4 | [-ln(1-α)]1/4 | |

| 反应机理 | 符号 | G(α) | |

|---|---|---|---|

| 化学反应机理 | 一步反应 | F1 | -ln(1-α) |

| 一步半反应 | F1.5 | 2[(1-α)-1/2-1] | |

| 两步反应 | F2 | (1-α)-1-1 | |

| 三步反应 | F3 | [(1-α)-2-1]/2 | |

| 扩散机理 | 一维扩散 | D1 | α2 |

| 二维扩散 | D2 | (1-α)ln(1-α)+α | |

| 三维扩散 | D3 | [1-(1-α)1/3]2 | |

| 四维扩散 | D4 | 1-(2/3)α-(1-α)2/3 | |

| 幂率 | 1/2幂定律反应 | P2 | α1/2 |

| 1/3幂定律反应 | P3 | α1/3 | |

| 指数定律反应 | P4 | α1/4 | |

| 相界面反应机理 | 一维反应 | R1 | α |

| 二维反应 | R2 | 1-(1-α)1/2 | |

| 三维反应 | R3 | 1-(1-α)1/3 | |

| 随机成核与生长反应机理 | 成核生长(n=1.5) | A1.5 | [-ln(1-α)]2/3 |

| 成核生长(n=2) | A2 | [-ln(1-α)]1/2 | |

| 成核生长(n=3) | A3 | [-ln(1-α)]1/3 | |

| 成核生长(n=4) | A4 | [-ln(1-α)]1/4 | |

| 1 | Mirkarimi A S M R, Bensad A S, Chiaramont D. Conversion of mixed waste plastic into fuel for diesel engines through pyrolysis process: A review[J]. Applied Energy, 2022, 327:120040 |

| 2 | 王红秋, 付凯妹.新形势下我国废塑料回收利用产业现状与思考[J]. 塑料工业,2022,50(6):38⁃42 |

| WANG H Q, FU K M. Status quo and thinking of China's waste plastic recycling recycling industry under the new situation [J]. Plastics Industry, 2022,50(6): 38⁃42. | |

| 3 | 李超.废塑料循环或将成为白色污染“终结者”[J]. 石油石化绿色低碳,2022,7(3):1⁃5,16. |

| LI C. Recycling of waste plastics may become the "terminator" of white pollution[J]. Petroleum and Petrochemical Green and Low Carbon, 2022, 7(3): 1⁃5,16. | |

| 4 | 崔华松.挥发性有机物的污染现状及治理策略研究[J]. 清洗世界,2023,39(2):77⁃79. |

| CUI H S. Research on the pollution status and treatment strategies of volatile organic compounds[J]. Clean World, 2023,39(2): 77⁃79. | |

| 5 | YOUSEF Samy, EIMONTAS Justas, STRIUGAS Nerijus, et al. Pyrolysis kinetic behaviour, TG⁃FTIR, and GC/MS analysis of cigarette butts and their components[J]. Biomass Conversion and Biorefinery, 2021, 156:105⁃118. |

| 6 | DIAS Pablo, JAVIMCZIK Selene, BENEVIT Mariana, et al. Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules[J]. Waste Manag, 2017, 60:716⁃722. |

| 7 | Du Y F, Ju T Y, Yuan M, et al. Pyrolysis characteristics of excavated waste and generation mechanism of gas products[J]. SSRN Electronic Journal, 2022, 370:133489. |

| 8 | 邢语彤,张一唯,卢平. 粘胶纤维/杨木共水热炭的燃烧和热解特性[J/OL]. 环境工程, 2023: 1⁃10. |

| XING Y T, ZHANG Y W, LU P. Combustion and pyrolysis characteristics of viscose fiber/poplar wood co hydrothermal carbon[J/OL]. Environmental Engineering, 2023: 1⁃10 | |

| 9 | Reshad ALI, PANKA Tiwari, V.Goud VAIBHAV. Thermal and co⁃pyrolysis of rubber seed cake with waste polystyrene for bio⁃oil production[J]. Analytical and Applied Pyrolysis, 2019, 139:333⁃343. |

| 10 | DADI Suriapparao, KUMAR Dharavath, VINU Ravikrishnan. Microwave co⁃pyrolysis of PET bottle waste and rice husk: effect of plastic waste loading on product formation[J]. Sustainable Energy Technologies and Assessments,2021, 49:101781. |

| 11 | Zhou J J, Liu G J, Xu F F, et al. TG⁃FTIR and Py⁃GC/MS study of the pyrolysis mechanism and composition of volatiles from flash pyrolysis of PVC[J]. Energy Institute, 2020, 175:288⁃297. |

| 12 | 李丹. 废橡塑热解机理及多环芳烃生成机制研究[D]. 天津:天津大学, 2021. |

| 13 | YOUSELF Samy, IEVA Kiminaitė, JUSTAS Eimontas, et al. Recovery of phenol and acetic acid from glass fibre reinforced thermoplastic resin using catalytic pyrolysis process on ZSM-5 zeolite catalyst and its kinetic behaviour[J]. Thermochimica Acta, 2022, 715:179293. |

| 14 | Peng H M, Li P L, Yang Q. Pyrolysis of polyester and viscose fiber over ZSM-5: synergistic effect and distribution of products[J]. Journal of Thermal Analysis and Calorimetry, 2022, 147:12 535⁃12 545. |

| 15 | 赵菲菲, 冯自松, 陈金海. 生活垃圾焚烧发电厂二噁英近零排放技术研究[J]. 环境科学与管理, 2016, 41(4):78⁃81. |

| ZHAO F F, FENG Z S, CHEN J H. Study on near⁃zero dioxin emission technology in domestic waste incineration power plant[J]. Environmental Science and Management, 2016, 41(4):78⁃81. | |

| 16 | 范春龙, 钱立新, 丁龙, 等. 废铜漆包线热解烟气中二噁英的排放特性与减排机理[J/OL]. 中国环境科学, 2023. |

| FAN C L, QIAN L X, DING L, et al. Emission characteristics and emission reduction mechanism of dioxins in pyrolysis flue gas of scrap copper enameled wire[J/OL]. China Environmental Science, 2023:19674. | |

| 17 | 邓悠娴. PVC热处理脱氯抑制二噁英生成技术[D]. 兰州:兰州大学, 2021. |

| 18 | 陈春燕, 谢煜婷. 有机固废气化装置及污染治理实施的研究[J]. 资源节约与环保, 2022, 8:84⁃87. |

| CHEN C Y, XIE Y T. Research on organic solid waste gasification device and pollution control implementation[J]. Resource Conservation and Environmental Protection, 2022, 8:84⁃87. | |

| 19 | Paladino Ombretta, Moranda Arianna. Human health risk assessment of a pilot⁃plant for catalytic pyrolysis of mixed waste plastics for fuel production[J]. Hazard Mater,2021, 405:124222. |

| 20 | 谢启源, 陈丹丹, 丁延伟. 热重分析技术及其在高分子表征中的应用[J]. 高分子学报, 2022,53(2):193⁃ 210. |

| XIE Q Y, CHEN D D, DING Y W. Thermogravimetric analysis technology and its application in polymer characterization[J]. Journal of Polymer Science, 2022, 53 (2): 193⁃210. | |

| 21 | 赵凤杰,刘剑.煤的热重分析技术及其应用[J].辽宁工程技术大学学报,2005,(S2):25⁃27. |

| ZHAO F J, LIU J. Thermogravimetric analysis technology and its application of coal[J]. Journal of Liaoning University of Engineering and Technology, 2005, (S2): 25⁃27. | |

| 22 | 成青.热重分析技术及其在高分子材料领域的应用[J].广东化工,2008,35(12):50⁃52,81. |

| CHENG Q. Thermogravimetric analysis technology and its application in the field of polymer materials[J]. Guangdong Chemical Industry, 2008, 35 (12): 50⁃52,81. | |

| 23 | Chen R Y, Xu X K, Lu S X, et al. Pyrolysis study of waste phenolic fibre⁃reinforced plastic by thermogravimetry/Fourier transform infrared/mass spectrometry analysis[J]. Energy Conversion and Management, 2018, 165(1):555⁃566. |

| 24 | Wu X J, BOURBIGOT S, LI K Y, et al. Co⁃pyrolysis characteristics and flammability of polylactic acid and acrylonitrile⁃butadiene⁃styrene plastic blend using TG, temperature⁃dependent FTIR, Py⁃GC/MS and cone calorimeter analyses[J]. Fire Safety Journal, 2022, 128:103543. |

| 25 | Tang X J, Cheng Z H, Liu J Y, et al. Dynamic pyrolysis behaviors, products, and mechanisms of waste rubber and polyurethane bicycle tires[J]. Hazardous Materials, 2021, 402(1):123516. |

| 26 | ACHYUT Panda, SATYANARAYAN Patnaik, SACHIN Kumar. Pyrolysis kinetics of keyboard plastic waste using thermogravimetric analyser to assess its energy potential[J]. Environmental Engineering and Landscape Management, 2022, 30: 259⁃267. |

| 27 | 刘全义, 马凯庆, 朱倩, 等.民航客机货舱侧壁板材料的热解特性[J].塑料工业,2023,51(1):108⁃112,136. |

| LIU Q Y, MA K Q, ZHU Q, et al. Pyrolysis characteristics of cargo side panel materials of airliner[J]. Plastics Industry, 2023,51(1): 108⁃112,136 | |

| 28 | 田霖, 胡建杭, 刘慧利. 基于热重⁃红外联用技术分析油酸的热解特性及动力学分析[J]. 化工进展, 2020, 39(S2):152⁃161. |

| TIAN L, HU J H, LIU H L. Analysis of the pyrolysis characteristics and kinetics of oleic acid based on thermogravimetric infrared spectroscopy[J]. Progress in Chemical Industry, 2020, 39 (S2): 152⁃161. | |

| 29 | WANIGONO Fassinou, LAURENT Van de steene, Toure Siaka, et al. Pyrolysis of Pinus pinaster in a two⁃stage gasifier: Influence of processing parameters and thermal cracking of tar[J]. Fuel Processing Technology, 2009, 90(1):75⁃90. |

| 30 | Ma S J, Long H N, He L M, et al. Effects of pressure and residence time on limonene production in waste tires pyrolysis process[J]. Analytical and Applied Pyrolysis, 2020,151:104899. |

| 31 | LELE Aditya Dilip, JU Yiguang. Assessment of the impact of reactor residence time distribution on non⁃equilibrium product selectivity of polypropylene pyrolysis using reactive molecular dynamics simulations[J]. Fuel, 2023, 338:127328. |

| 32 | KULAS Daniel, ZOLGHADR Ali, SHONNARD David. Micropyrolysis of polyethylene and polypropylene prior to bioconversion: the effect of reactor temperature and vapor residence time on product distribution[J]. ACS Sustainable Chemistry & Engineering. 2021, 9:14 443⁃14 450. |

| 33 | Yue C Y, Gao P P, Tang L F, et al. Effects of N2/CO2 atmosphere on the pyrolysis characteristics for municipal solid waste pellets[J]. Fuel, 2022, 315:123233. |

| 34 | Yan M, Zhou X, Zhang S C, et al. Municipal solid waste pyrolysis under circulated pyrolytic gas atmosphere[J]. Material Cycles and Waste Management, 2021: 23. |

| 35 | GRZYWACZ Przemysław, CZERSKI Grzegorz, GANCZARCZYK Wojciech. Effect of pyrolysis atmosphere on the gasification of waste tire char[J]. Energies, 2021, 15: 35. |

| 36 | 李亚玲,张伟民. 乳酸/己内酯共聚物的差示扫描量热分析[J]. 北京印刷学院学报, 2006, 4(13):39⁃41. |

| LI Y L, ZHANG W M. Differential scanning calorimetric analysis of lactic acid/caprolactone copolymer[J]. Beijing Institute of Graphic Arts, 2006, 4(13):39⁃41. | |

| 37 | 逄翠翠, 谢平平, 张文杰, 等. 浅谈差示扫描量热法应用[C]//中国润滑技术论坛(2018)暨中国汽车工程学会汽车燃料与润滑油分会第十八届年会论文专辑. 苏州: China Academic Journal Electronic Publishing House,2018:415⁃418. |

| 38 | Qin L B, Han J, Zhao B, et al. Thermal degradation of medical plastic waste by in⁃situ FTIR, TG⁃MS and TG⁃GC/MS coupled analyses[J]. Journal of Analytical and Applied Pyrolysis, 2018, 136:132⁃145. |

| 39 | 贺金娴. 差热分析在塑料工业中的应用[J]. 江苏化工, 1983, (2):56⁃62. |

| HE J X. Application of differential thermal analysis in plastics industry[J]. Jiangsu Chemical Industry, 1983, (2):56⁃62. | |

| 40 | 马洪亭, 王芳超, 杨国利, 等. 三种典型医疗废物热解过程的差热分析[J]. 化工进展,2012, 31(4):933⁃937. |

| MA H T, WANG F C, YANG G L, et al. Differential thermal analysis of pyrolysis processes of three typical medical wastes[J]. Chemical Industry and Engineering Progress, 2012, 31(4):933⁃937. | |

| 41 | 杨丹. 差热分析法在聚酯监测中的应用[J]. 聚酯工业, 2019, 32(3):25⁃27. |

| YANG D. Application of differential thermal analysis method in polyester monitoring[J]. Polyester Industry, 2019, 32(3):25⁃27. | |

| 42 | 李茜茜, 冯俊小. 有机固废热解动力学的研究进展[J]. 环境工程, 2022, 40(10):215⁃223. |

| LI Q X, FENG J X. Research progress on pyrolysis kinetics of organic solid waste[J]. Environmental Engineering, 2022, 40(10):215⁃223. | |

| 43 | KREMER Irma, TOMIC Tihomir, KATANCIC Zvonimir, et al. Catalytic pyrolysis and kinetic study of real⁃world waste plastics: multi⁃layered and mixed resin types of plastics[J]. Clean Technologies and Environmental Policy, 2022, 24:10. |

| 44 | PRABHAKAR Ashok, SADHUKHAN Anup Kumar, GUPTA Parthapratim. Study of pyrolysis kinetics of coal fines using model free method[J]. Materials Today: Proceedings, 2022, 68(4):910⁃915. |

| 45 | Hu Y D, Liu J, Li X M, et al. Assessment of the pyrolysis kinetics and mechanism of vegetable⁃tanned leathers[J]. Analytical and Applied Pyrolysis, 2022, 164: 105502 |

| 46 | 骆强, 曲芳, 姚志鹏, 等.典型航空电缆的热解动力学研究[J].华南师范大学学报(自然科学版), 2021, 53(5):30⁃36. |

| LUO Q, QU F, YAO Z P, et al.Pyrolysis kinetics study of typical aviation cables[J]. South China Normal University (Natural Science Edition), 2021, 53(5):30⁃36. | |

| 47 | 刘盈孜. 聚酰亚胺热解机理的研究[D]. 北京:北京化工大学,2021. |

| 48 | Ding Z Y, Chen H S, Liu J Y, et al. Pyrolysis dynamics of two medical plastic wastes: drivers, behaviors, evolved gases, reaction mechanisms, and pathways[J]. Hazardous Materials, 2020, 402: 123472. |

| 49 | MENARES Tamara, HERRERA Jorge, ROMERO Romina, et al. Arteaga⁃pérez,waste tires pyrolysis kinetics and reaction mechanisms explained by TGA and Py⁃GC/MS under kinetically⁃controlled regime[J]. Waste Management, 2020, 102: 21⁃29. |

| 50 | Chen J W, Ma X Q, Yu Z S, et al. A study on catalytic co⁃pyrolysis of kitchen waste with tire waste over ZSM-5 using TG⁃FTIR and Py⁃GC/MS[J]. Bioresource Technology, 2019, 289: 12585. |

| 51 | SINGH Gajendra, VERMA Anil, ALMAS Sadiya, et al. Pyrolysis kinetic study of waste milk packets using thermogravimetric analysis and product characterization[J]. Journal of Material Cycles and Waste Management, 2019: 21. |

| 52 | Yao Z T, Yu S Q, Su W P, et al. Kinetic studies on the pyrolysis of plastic waste using a combination of modelfitting and model⁃free methods[J]. Waste Management & Research, 2020, 38: 77⁃85. |

| 53 | Pallab DAS, TIWARI Pankaj. Thermal degradation kinetics of plastics and model selection[J]. Thermochim Acta, 2017, 654: 191⁃202. |

| 54 | ABOULKAS A, El Harfi K, El Bouadili A. Thermal degradation behaviors of polyethylene and polypropylene[J]. Thermochimica Acta, 2010, 51:1 363⁃1 369. |

| 55 | 张公妍, 张延松, 陈昆, 等.模式拟合法和无模式函数法对月桂酸热解行为及机理的研究[J]. 日用化学工业, 2021, 51(04): 265⁃271. |

| ZHANG G Y, ZHANG Y S, CHEN K, et al. Study on behavior and mechanism of lauric acid pyrolysis by mode fitting and mode afree function method[J]. Daily Chemical Industry, 2021, 51(4): 265⁃271. | |

| 56 | Shan T L, Bian H G, Wang K S, et al.Study on pyrolysis characteristics and kinetics of mixed waste plastics under different atmospheres[J]. Thermochimica Acta, 2023, 722, 179467. |

| 57 | Chen Z W, Liu L H, Wang H, et al. Pyrolysis Characteristics and non⁃isothermal kinetics of integrated circuits[J]. Materials, 2022, 13(4 460): 10. |

| 58 | SAHA D, SINHA A, PATTANAYAK S . et al. Pyrolysis kinetics and thermodynamic parameters of plastic grocery bag based on thermogravimetric data using iso⁃conversional methods[J]. International Journal of Environmental Science and Technology, 2022, 19:391⁃406. |

| 59 | Chen X Y, Cai D, Yang Y M, et al. Pyrolysis kinetics of bio⁃based polyurethane: Evaluating the kinetic parameters, thermodynamic parameters, and complementary product gas analysis using TG/FTIR and TG/GC⁃MS[J]. Renewable Energy, 2023, 205:490⁃498. |

| 60 | Park Ki⁃Bum, Kim Joo⁃Sik. Pyrolysis products from various types of plastics using TG⁃FTIR at different reaction temperatures[J]. Journal of Analytical and Applied Pyrolysis, 2023, 171:105983, |

| 61 | Sun Y N, Zhang H N, Zhang F, et al. Pyrolysis properties and kinetics of photocured waste from photopolymerization⁃based 3D printing: A TG⁃FTIR/GC⁃MS study[J]. Waste Management, 2022, 150:151⁃160. |

| 62 | 田原宇, 吕永康, 谢克昌. PVC的热解/红外(Py/FTIR)研究[J]. 燃料化学学报, 2002, 6:569⁃572. |

| TIAN Y Y, LV Y K, XIE K C. Pyrolysis and infrared (Py/FTIR) study of PVC[J]. Journal of fuel Chemistry, 2002, 6:569⁃572. | |

| 63 | 罗希韬, 王志奇, 武景丽, 等. 基于热重红外联用分析的PE、PS、PVC热解机理研究[J]. 燃料化学学报, 2012, 40(9): 1 147⁃1 152. |

| LUO X T, WANG Z Q, WU J L, et al. Study on pyrolysis mechanism of PE, PS and PVC based on thermogravimetric infrared analysis[J]. Journal of Fuel Chemistry and Technology, 2012, 40(9): 1 147⁃1 152. | |

| 64 | 吕全伟, 林顺洪, 柏继松, 等. 热重⁃红外联用(TG⁃FTIR)分析含油污泥⁃废轮胎混合热解特性[J]. 化工进展, 2017, 36(12): 4 692⁃4 699. |

| LV Q W, LIN S H, Bai J S, et al. Analysis of pyrolysis characteristics of oily sludge⁃waste tire mixture by TG⁃FTIR[J]. Chemical Industry and Engineering Progress, 2017, 36(12): 4 692⁃4 699. | |

| 65 | BATUER Adili, LONG Jisheng, DU Hailiang, et al. Multi⁃products oriented co⁃pyrolysis of papers, plastics, and textiles in MSW and the synergistic effects[J]. Journal of Analytical and Applied Pyrolysis, 2022, 163:105478. |

| 66 | 赫树开, 曾晓哲, 齐汝宾, 等. 基于FTIR的高压电器用T型电缆插头热解行为研究[J]. 绝缘材料, 2021, 54(4):91⁃94. |

| HE S K, ZENG X Z, QI R B, et al. Study on pyrolysis behavior of T⁃type cable plug for high⁃voltage electrical apparatus based on FTIR[J]. Insulating Materials, 2021, 54(4):91⁃94. | |

| 67 | REINERTE Sanita, AVOTINA Liga, ZARINS Arturs, et al. TG/DTA⁃FTIR as a method for analysis of tall oil based rigid polyurethane foam decomposition gaseous products in a low oxygen environment[J]. Polymer Degradation and Stability, 2020, 180: 109313. |

| 68 | SEBASTIAN Alarcon Salinas, PETER Kusch, GERD Knupp, et al. Characterization and quantification of poly(acrylonitrile⁃co⁃1,3⁃butadiene⁃co⁃styrene)/polyamide 6 (ABS/PA6) blends using pyrolysis⁃gas chromatography (Py⁃GC) with different detector systems[J]. Journal of Analytical & Applied Pyrolysis, 2016, 122(11):452⁃457. |

| 69 | 于惠梅, 张青红, 齐玲均, 等.热分析⁃质谱联用中逸出气体的脉冲热分析定量方法[J]. 中国科学:化学, 2010, 40(9): 1 402⁃1 408. |

| YU H M, ZHANG Q H, QI L J, et al. Quantitative method for impulsive thermal analysis of escaped gas in thermal analysis⁃mass spectrometry[J]. Science China Chemistry, 2010, 40(9): 1 402⁃1 408. | |

| 70 | 李卫青, 贾德民, 傅伟文, 等. 采用热重和裂解气相色谱⁃质谱分析方法剖析轮胎硫化胶[J]. 弹性体, 2002,1:52⁃57. |

| LI W Q, JIA D M, FU W W, et al. Analysis of tire vulcanized rubber by thermogravimetric and pyrolysis gas chromatography⁃mass spectrometry[J]. Elastomers, 2002, 1:52⁃57. | |

| 71 | 郭振戈. 基于py⁃gc/ms及原位红外纤维素热解机理研究[D].广州: 华南理工大学, 2016. |

| 72 | 潘永红, 王万卷, 余巧玲, 等. 基于热重分析和热裂解气相色谱⁃质谱联用法的液晶聚合物热裂解成分检测[J]. 塑料科技, 2016, 44(1): 90⁃93. |

| PAN Y H, WANG W J, YU Q L, et al. Determination of pyrolysis components of liquid crystal polymers based on thermogravimetric analysis and pyrolysis gas chromatography⁃mass spectrometry[J]. Plastic Science and Tec⁃hnology, 2016, 44(1): 90⁃93. | |

| 73 | Li B Y, Wang X L, Xia Z D, et al. Co⁃pyrolysis of waste polyester enameled wires and polyvinyl chloride: Evolved products and pyrolysis mechanism analysis[J]. Journal of Analytical and Applied Pyrolysis, 2022, 169: 105816. |

| 74 | MENARES Tapia Tamara, HERRERA Jorge, ROMERO Romina, et al. Waste tires pyrolysis kinetics and reaction mechanisms explained by TGA and Py⁃GC/MS under kinetically⁃controlled regime[J]. Waste management, 2019, 102:21⁃29. |

| 75 | Xu F F, Wang B, Yang D, et al. TG⁃FTIR and Py⁃GC/MS study on pyrolysis mechanism and products distribution of waste bicycle tire[J]. Energy Conversion and Management, 2018, 175:288⁃297. |

| 76 | Supriyanto, Ylitervo Päivi, Richards Tobias. Gaseous products from primary reactions of fast plastic pyrolysis[J].Journal of Analytical and Applied Pyrolysis, 2021, 158:105248. |

| 77 | Straka Pavel, Bičáková Olga, Šupová Monika. Slow pyrolysis of waste polyethylene terephthalate yielding paraldehyde, ethylene glycol, benzoic acid and clean fuel[J]. Polymer Degradation and Stability, 2022, 198:109900. |

| 78 | Zhou J J, Liu G J, Wang S B, et al.TG⁃FTIR and Py⁃GC/MS study of the pyrolysis mechanism and composition of volatiles from flash pyrolysis of PVC[J]. Journal of the Energy Institute, 2020, 93:2 362⁃2 370. |

| 79 | Peng Y J, Wang Y P, Ke L Y. A review on catalytic pyrolysis of plastic wastes to high⁃value products[J]. Energy Conversion and Management, 2022, 254:115243. |

| 80 | Zhang Y T, Fu Z G, Wang W, et al. Kinetics, product evolution, and mechanism for the pyrolysis of typical plastic waste[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(1): 91⁃103. |

| 81 | Xie W, Su J, Zhang X K, et al. Investigating kinetic behavior and reaction mechanism on autothermal pyrolysis of polyethylene plastic[J]. Energy, 2023, 269:126817. |

| 82 | Oenema Jogchum, Liu Haoran, Nathalie De Coensel, et al. Review on the pyrolysis products and thermal decomposition mechanisms of polyurethanes[J].Journal of Analytical and Applied Pyrolysis, 2023, 168:105723. |

| 83 | Chen G Y, Liu T C, Luan P P,et al. Distribution, migration, and removal of N⁃containing products during polyurethane pyrolysis: A review[J]. Journal of Hazardous Materials, 2023, 453:131406. |

| 84 | Yang J, Wu Y F, Zhu J L, et al. Insight into the pyrolysis behavior of polyvinyl chloride using in situ pyrolysis time⁃of⁃flight mass spectrometry: Aromatization mechanism and Cl evolution[J]. Fuel, 2023, 331:125994. |

| 85 | 孙锴. 废塑料催化热解制备芳香烃的研究[D]. 杭州:浙江大学, 2021. |

| 86 | Cunliffe A M, Williams P T. Composition of oils derived from the batch pyrolysis of tyres[J]. Journal of Analytical and Applied Pyrolysis, 1998, 44(2):131⁃152. |

| 87 | Banar M, Akyıldız V, Özkan A, et al. Characterization of pyrolytic oil obtained from pyrolysis of TDF (Tire Derived Fuel)[J]. Energy Conversion and Management, 2012, 62: 22⁃30. |

| 88 | 刘晓静, 吴玉锋, 李彬, 等. 废线路板典型利用处置技术污染防控研究进展[J]. 有色金属(冶炼部分), 2021,(10):71⁃80. |

| LIU X J, WU Y F, LI B, et al. Research progress on pollution prevention and control of typical utilization and disposal technology of waste circuit boards[J]. Nonferrous Metals(Smelting Part), 2021, (10):71⁃80. |

| [1] | 马秀清, 劳志超, 李明谦, 韩顺涛, 胡楠. 螺杆构型对PLA/PTW共混物性能影响的研究[J]. 中国塑料, 2023, 37(11): 127-134. |

| [2] | 吕冲, 朱雯雯, 史正雪, 加英姿, 江学良, 游峰, 黄李纲, 姚楚, 刘仿军. 高降噪聚合物基复合材料的制备及声学性能研究进展[J]. 中国塑料, 2023, 37(11): 170-177. |

| [3] | 马俊丞, 徐双平, 王馨甜, 贾宏葛, 张明宇, 蘧延庆. 生物基材料在碘吸附中的研究进展[J]. 中国塑料, 2023, 37(11): 178-191. |

| [4] | 赵合瑾, 万贤, 路佳慧, 张红雨, 郭宝华. 相变储能材料在建筑领域的发展和应用[J]. 中国塑料, 2023, 37(11): 46-61. |

| [5] | 李田华, 白林, 孙颖. 4种方法测定聚烯烃管材和管件中的炭黑含量[J]. 中国塑料, 2023, 37(11): 95-100. |

| [6] | 李红伟, 章勇锋, 齐武军, 阮刚勇, 阮沥波, 方宇超. 聚乙烯管道及其增强复合管道在实际工程应用中的问题[J]. 中国塑料, 2023, 37(8): 69-78. |

| [7] | 杨天学, 杨哲, 张军平, 王铭, 龚天成, 张婷, 侯佳奇, 席北斗. 国内外可降解膜研究热点及趋势对比分析[J]. 中国塑料, 2023, 37(1): 119-132. |

| [8] | 杨旭, 方健, 覃敏, 于雷. 壳聚糖/结冷胶双层膜制备工艺优化及表征[J]. 中国塑料, 2022, 36(11): 14-23. |

| [9] | 杨波, 杨圳, 曾辰, 王志刚, 翟伟, 曹福想. 基于循环载荷试验的聚乙烯管材寿命预测研究[J]. 中国塑料, 2022, 36(9): 63-69. |

| [10] | 李岩, 唐晓旭, 张伟杰, 黄瑞鹏, 张杉. 基于应变硬化模量方法评价聚乙烯管材耐慢速裂纹增长性能研究进展[J]. 中国塑料, 2022, 36(9): 148-159. |

| [11] | 林健辉, 卢嘉慧, 吴欣颖, 范雪滢, 邓桂荣, 高亮, 梅承芳, 杨永刚. 受控堆肥条件下可降解材料最终需氧生物分解能力测定的不确定度评定研究[J]. 中国塑料, 2022, 36(9): 140-147. |

| [12] | 何安淇, 黄剑, 张莹, 孙华丽, 项爱民, 徐海云. 喷水灭火氯化聚氯乙烯管道的压力设计基础及国内外标准比较[J]. 中国塑料, 2022, 36(9): 131-139. |

| [13] | 张兵. 无规共聚聚丙烯管材氧化诱导时间测试探究[J]. 中国塑料, 2022, 36(8): 107-109. |

| [14] | 刘义, 王叶, 孙伟, 曲国兴, 许霞, 杨少林, 袁宁. 红外光谱法测定聚丙烯中透明成核剂含量研究[J]. 中国塑料, 2022, 36(8): 115-118. |

| [15] | 张鑫, 全淑苗. 基于中国政策的废旧农膜回收再利用现状研究[J]. 中国塑料, 2022, 36(7): 136-142. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2