京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (6): 118-125.DOI: 10.19491/j.issn.1001-9278.2025.06.020

• 综述 • 上一篇

涂著1,2( ), 马会霞1, 李澜鹏1, 周峰1, 魏志勇2(

), 马会霞1, 李澜鹏1, 周峰1, 魏志勇2( )

)

收稿日期:2024-07-15

出版日期:2025-06-26

发布日期:2025-06-20

通讯作者:

魏志勇,主要从事生物基可降解聚酯新材料的研究,zywei@dlut.edu.cn作者简介:涂著,博士,主要从事高分子物理结构与性能关系的研究,tuzhu.fshy@sinopec.com

基金资助:

TU Zhu1,2( ), MA Huixia1, LI Lanpeng1, ZHOU Feng1, WEI Zhiyong2(

), MA Huixia1, LI Lanpeng1, ZHOU Feng1, WEI Zhiyong2( )

)

Received:2024-07-15

Online:2025-06-26

Published:2025-06-20

Contact:

WEI Zhiyong

E-mail:tuzhu.fshy@sinopec.com;zywei@dlut.edu.cn

摘要:

以可生物降解聚酯塑料在海洋环境中的降解性能研究为出发点,总结了目前部分被报道的典型可海水降解聚酯材料,并从降解材料种类和降解机理的角度讨论了可降解聚酯材料在海水中的降解行为差异及相应的材料改性方法。最后,基于可海水降解聚酯材料的设计以及存在的挑战,提出了相应的建议与思考。

中图分类号:

涂著, 马会霞, 李澜鹏, 周峰, 魏志勇. 可海水降解聚酯塑料的研究进展[J]. 中国塑料, 2025, 39(6): 118-125.

TU Zhu, MA Huixia, LI Lanpeng, ZHOU Feng, WEI Zhiyong. Research progress in seawater⁃degradable polyester plastics[J]. China Plastics, 2025, 39(6): 118-125.

| 1 | Ghayebzadeh M, Aslani H, Taghipour H, et al. Estimation of plastic waste inputs from land into the Caspian Sea: A significant unseen marine pollution[J]. Marine Pollution Bulletin, 2020, 151: 110871. |

| 2 | Geyer R, Jambeck J R, Law K L. Production, use, and fate of all plastics ever made[J]. Science Advances, 2017, 3(7): 1⁃5. |

| 3 | From pollution to solution⁃A global assessment of marien litter and plastic pollution[]J/OL. . |

| 4 | 金林宇 何思远, 李 丹, 等. 可降解材料现状及其在海洋领域的研究进展[J]. 包装工程, 2020, 41(19): 108⁃115. |

| JIN L Y, HE S Y, LI D, et al. Status of degradable materials and their progress in marine research[J]. Packaging Engineering, 2020, 41(19): 108⁃115. | |

| 5 | 邹文奇, 陈 通, 叶海木, 等. 可生物降解聚酯的制备及性能研究进展[J]. 化工学报, 2021, 72(12): 6216⁃6231. |

| ZOU W Q, CHEN T, YE H M, et al. Research progress on the preparation and properties of biodegradable polyester[J]. CIESC Journal, 2021, 72(12): 6 216⁃6 231. | |

| 6 | Andrady A L. Microplastics in the marine environment[J]. Marine Pollution Bulletin, 2011, 62(8): 1 596⁃1 605. |

| 7 | Samalens F, Thomas M, Claverie M, et al. Progresses and future prospects in biodegradation of marine biopolymers and emerging biopolymer⁃based materials for sustainable marine ecosystems[J]. Green Chemistry, 2022, 24(5): 1 762⁃1 779. |

| 8 | Wang G X, Huang D, Ji J H, et al. Seawater⁃degradable polymers ⁃ Fighting the marine plastic pollution[J]. Advanced Science, 2020, 8(1): 2001121. |

| 9 | 陈心宇, 李梦怡, 陈国强. 聚羟基脂肪酸酯PHA代谢工程研究30年[J]. 生物工程学报, 2021, 37(5): 1 794⁃1 811. |

| CHEN X Y, LI M Y, CHEN G Q. Thirty years of metabolic engineering for biosynthesis of polyhydroxyalkanoates[J]. Chinese Journal of Biotechnology, 2021, 37(5): 1 794⁃1 811. | |

| 10 | Tan D, Wang Y, Tong Y, et al. Grand challenges for industrializing polyhydroxyalkanoates (PHAs)[J]. Trends in Biotechnology, 2021, 39(9): 953⁃963. |

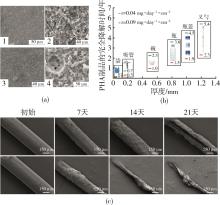

| 11 | Volova T G, Boyandin A N, Vasiliev A D, et al. Biodegradation of polyhydroxyalkanoates (PHAs) in tropical coastal waters and identification of PHA⁃degrading bacteria[J]. Polymer Degradation and Stability, 2010, 95(12): 2 350⁃2 359. |

| 12 | Volova T G, Boyandin A N, Vasil’ev A D, et al. Biodegradation of polyhydroxyalkanoates (PHAs) in the South China Sea and identification of PHA⁃degrading bacteria[J]. Microbiology, 2011, 80(2): 252⁃260. |

| 13 | Deroiné M, Le Duigou A, Corre Y M, et al. Seawater accelerated ageing of poly(3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate)[J]. Polymer Degradation and Stability, 2014, 105: 237⁃247. |

| 14 | Dilkes⁃Hoffman L S, Lant P A, Laycock B, et al. The rate of biodegradation of PHA bioplastics in the marine environment: A meta⁃study[J]. Marine Pollution Bulletin, 2019, 142: 15⁃24. |

| 15 | Omura T, Komiyama K, Maehara A, et al. Elastic marine biodegradable fibers produced from poly[(R)⁃3⁃hydroxybutylate⁃co-4⁃hydroxybutylate] and evaluation of their biodegradability[J]. ACS Applied Polymer Materials, 2021, 3(12): 6 479⁃6 487. |

| 16 | Marín A, Feijoo P, de Llanos R, et al. Microbiological characterization of the biofilms colonizing bioplastics in natural marine conditions: A comparison between PHBV and PLA[J]. Microorganisms, 2023, 11(6):1 461. |

| 17 | Gabirondo E, Sangroniz A, Etxeberria A, et al. Poly(hydroxy acids) derived from the self⁃condensation of hydroxy acids: from polymerization to end⁃of⁃life options[J]. Polymer Chemistry, 2020, 11(30): 4 861⁃4 874. |

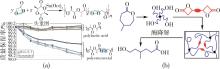

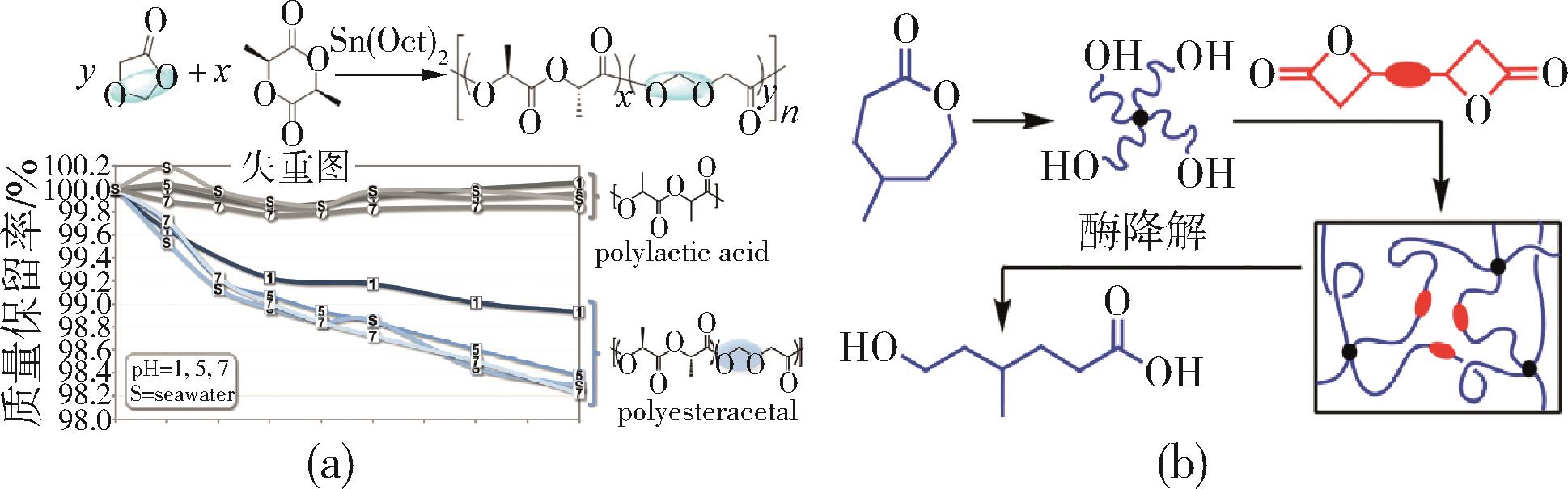

| 18 | 孙炳新, 揣成智, 韩春阳, 等. 水生环境下脂肪族聚酯生物降解性能研究进展[J]. 包装工程, 2012, 33(11): 129⁃134. |

| SUN B X, CHUAI C Z, HAN C Y, et al. Research progress in biodegradation of aliphatic polyesters under aquatic environment[J]. Packaging Engineering, 2012, 33(11): 129⁃134. | |

| 19 | Sekiguchi T, Saika A, Nomura K, et al. Biodegradation of aliphatic polyesters soaked in deep seawaters and isolation of poly(ɛ⁃caprolactone)⁃degrading bacteria[J]. Polymer Degradation and Stability, 2011, 96(7): 1 397⁃1 403. |

| 20 | Nakayama A, Yamano N, Kawasaki N. Biodegradation in seawater of aliphatic polyesters[J]. Polymer Degradation and Stability, 2019, 166: 290⁃299. |

| 21 | 王格侠, 黄 丹, 张 维, 等. 典型生物降解聚酯在海水中的降解性能[J]. 功能高分子学报, 2020, 33(5): 492⁃499. |

| WANG G X, HUANG D, ZHANG W, et al. Degradation performance of typical biodegradable polyesters in seawater[J]. Journal of Functional Polymers, 2020, 33(5): 492⁃499. | |

| 22 | Lu B, Wang G X, Huang D, et al. Comparison of PCL degradation in different aquatic environments: Effects of bacteria and inorganic salts[J]. Polymer Degradation and Stability, 2018, 150: 133⁃139. |

| 23 | Segawa T, Ito K, Hatayama M, et al. Visualization of changes in crystallinity and intermolecular hydrogen bonding of poly(ε⁃caprolactone) during marine degradation process by high⁃ and low⁃frequency three⁃dimensional raman mapping[J]. ACS Applied Polymer Materials, 2024, 6(11): 6 408⁃6 415. |

| 24 | Lee J, Kim S, Park S B, et al. Mimicking real⁃field degradation of biodegradable plastics in soil and marine environments: From product utility to end⁃of⁃life analysis[J]. Polymer Testing, 2024, 131: 108338. |

| 25 | Jem K J, Tan B. The development and challenges of poly (lactic acid) and poly (glycolic acid)[J]. Advanced Industrial and Engineering Polymer Research, 2020, 3(2): 60⁃70. |

| 26 | Samantaray P K, Little A, Haddleton D M, et al. Poly(glycolic acid) (PGA): a versatile building block expanding high performance and sustainable bioplastic applications[J]. Green Chemistry, 2020, 22(13): 4 055⁃4 081. |

| 27 | Murcia Valderrama M A, van Putten R J, Gruter G J M. The potential of oxalic – and glycolic acid based polyesters (review). Towards CO2 as a feedstock (Carbon Capture and Utilization – CCU)[J]. European Polymer Journal, 2019, 119: 445⁃468. |

| 28 | 马 超, 马兰荣, 魏 辽, 等. 聚乙醇酸材料的加工改性及其水下降解特性的研究进展[J]. 中国塑料, 2022, 36(9): 74⁃84. |

| MA C, MA L R, WEI L, et al. A review of modification processing and water⁃soluble degradation ability of polyglycolic acid material[J]. China Plastics, 2022, 36(9): 74⁃84. | |

| 29 | 汪威雨. 聚乙交酯的水解性能及热稳定的研究[D]. 江苏: 江苏科技大学, 2019. |

| 30 | de Jonga S J, Arias E R, Rijkersb D T S, et al. New insights into the hydrolytic degradation of poly(lactic acid[J]. Polymer, 2001, 42: 2 795⁃2 802. |

| 31 | Woodard L N, Grunlan M A. Hydrolytic degradation and erosion of polyester biomaterials[J]. ACS Macro Letters, 2018, 7(8): 976⁃982. |

| 32 | 郭 正, 张佩华. 编织加工对聚羟基乙酸纤维降解性能的影响[J]. 东华大学学报, 2009, 35(5): 521⁃536. |

| GUO Z, ZHANG P H. Influence of braiding process on the performance of polyglycolic acid fibers during degradation in vitro[J]. Journal of donghua university(natural science), 2009, 35(5): 521⁃536. | |

| 33 | Nguyen H T H, Qi P, Rostagno M, et al. The quest for high glass transition temperature bioplastics[J]. Journal of Materials Chemistry A, 2018, 6(20): 9 298⁃9 331. |

| 34 | Carothers W H, Arvin J A, Dorough G E. Studies on polymerization and ring formation. V: Glycol esters of oxalic acid[J]. Journal of the American Chemical Society, 1930, 52: 3 292⁃3 300. |

| 35 | Garcia J J, Miller S A. Polyoxalates from biorenewable diols via oxalate metathesis polymerization[J]. Polymer Chemistry, 2014, 5(3): 955⁃961. |

| 36 | Tu Z, Lu Y, Zhang Y, et al. Development of poly(n⁃alkylene oxalate)s towards a new kind of seawater degradable plastics[J]. Materials Today Sustainability, 2023, 22: 100378. |

| 37 | Tu Z, Lu Y, Sang L, et al. Kilogram⁃scale preparation of poly(ethylene oxalate) toward marine⁃degradable plastics[J]. Macromolecules, 2023, 56:3 149⁃3 159. |

| 38 | 李秀峥, 白富栋, 孙启梅, 等. 乳酸⁃乙醇酸共聚物(PLGA)制备方法研究进展[J]. 当代化工, 2024, 53(3): 676⁃686. |

| LI X Z, BAI F D, SUN Q M, et al. Research progress in preparation methods of lactic acid⁃glycolic acid copolymer (PLGA)[J]. Contemporary chemical industry, 2024, 53(3): 676⁃686. | |

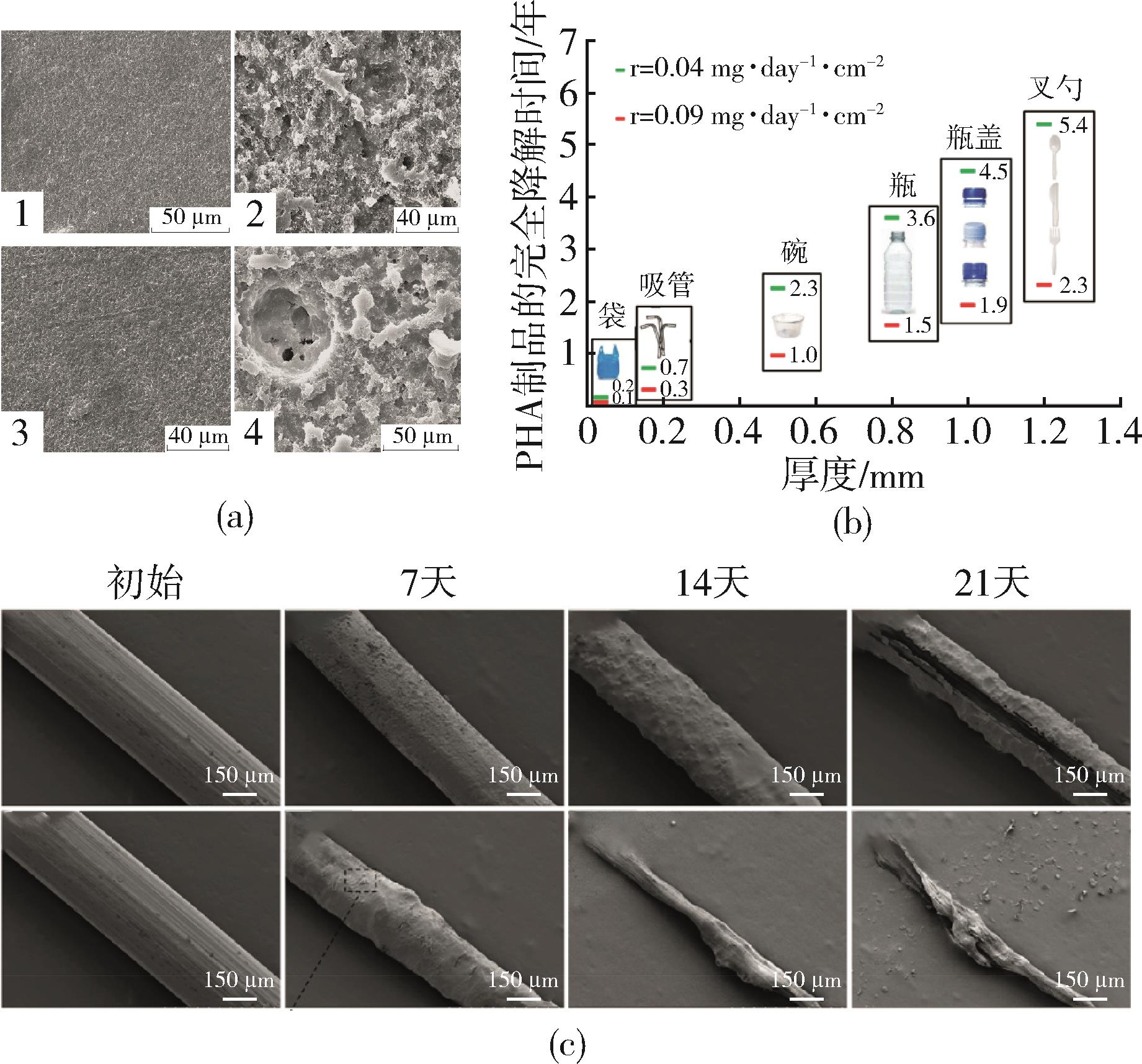

| 39 | Bagheri A R, Laforsch C, Greiner A, et al. Fate of so⁃called biodegradable polymers in seawater and freshwater[J]. Global Challenges, 2017, 1(4): 1700048. |

| 40 | Hu H, Li J, Tian Y, et al. Experimental and theoretical study on glycolic acid provided fast bio/seawater⁃degradable poly(butylene succinate⁃co⁃glycolate)[J]. ACS Sustainable Chemical & Engineering, 2021, 9(10): 3 850⁃3 859. |

| 41 | Arhant M, Le Gall M, Le Gac P Y, et al. Impact of hydrolytic degradation on mechanical properties of PET ⁃ Towards an understanding of microplastics formation[J]. Polymer Degradation and Stability, 2019, 161: 175⁃182. |

| 42 | Liu T Y, Xu P Y, Dan H, et al. Enhanced degradation of poly(ethylene terephthalate) by the addition of lactic acid / glycolic acid: composting degradation, seawater degradation behavior and comparison of degradation mechanism[J]. Journal of Hazardous Materials, 2023, 446: 130670. |

| 43 | Hu H, Zhang R, Wang J, et al. A mild method to prepare high molecular weight poly(butylene furandicarboxylate⁃co⁃glycolate) copolyesters: effects of the glycolate content on thermal, mechanical, and barrier properties and biodegradability[J]. Green Chemistry, 2019, 21(11): 3 013⁃3 022. |

| 44 | Ding Y, Huang D, Ai T, et al. Bio⁃based poly(butylene furandicarboxylate⁃co⁃glycolate) copolyesters: Synthesis, properties, and hydrolysis in different aquatic environments for water degradation application[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(3): 1 254⁃1 263. |

| 45 | Luan Q, Hu H, Jiang X, et al. Melt polycondensation of poly(butylene oxalate⁃co⁃succinate) with great potential in curbing marine plastic pollution[J]. Journal of Hazardous Materials, 2023, 457: 131801. |

| 46 | Tu Z, Wang L, Lu Y, et al. Rapid marine degradable poly(butylene oxalate) by introducing promotion building blocks[J]. Journal of Hazardous Materials, 2024, 462: 132791. |

| 47 | Wang Y, Davey C J E, van der Maas K, et al. Biodegradability of novel high Tg poly(isosorbide⁃co-1,6⁃hexanediol) oxalate polyester in soil and marine environments[J]. Science of the Total Environment, 2022, 815: 152781. |

| 48 | Luan Q, Hu H, Ouyang X, et al. New modifications of PBAT by a small amount of oxalic acid: Fast crystallization and enhanced degradation in all natural environments[J]. Journal of Hazardous Materials, 2024, 465: 133475. |

| 49 | Wang L, Tu Z, Liang J, et al. Poly(butylene oxalate⁃co⁃terephthalate): A PBAT⁃like but rapid hydrolytic degradation plastic[J]. Journal of Hazardous Materials, 2024, 471: 134349. |

| 50 | Liu T Y, Huang D, Xu P Y, et al. Biobased seawater⁃degradable poly(butylene succinate⁃L⁃lactide) copolyesters: Exploration of degradation performance and degradation mechanism in natural seawater[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(10): 3 191⁃3 202. |

| 51 | Tian Y, Hu H, Chen C, et al. Enhanced seawater degradation through copolymerization with diglycolic acid: Synthesis, microstructure, degradation mechanism and modification for antibacterial packaging[J]. Chemical Engineering Journal, 2022, 447: 137535. |

| 52 | Hu H, Tian Y, Wang J, et al. Enhanced degradation and gas barrier of PBAT through composition design of aliphatic units[J]. Polymer Degradation and Stability, 2022, 195: 109795. |

| 53 | He M, Hsu Y I, Uyama H. Superior sequence⁃controlled poly(L⁃lactide)⁃based bioplastic with tunable seawater biodegradation[J]. Journal of Hazardous Materials, 2024, 474: 134819. |

| 54 | Martin R T, Camargo L P, Miller S A. Marine⁃degradable polylactic acid[J]. Green Chemistry, 2014, 16(4): 1 768⁃1 773. |

| 55 | De Hoe G X, Zumstein M T, Tiegs B J, et al. Sustainable polyester elastomers from lactones: Synthesis, properties, and enzymatic hydrolyzability[J]. Journal of the American Chemical Society, 2018, 140(3): 963⁃973. |

| 56 | Guzman⁃Sielicka A, Janik H, Sielicki P. Proposal of new starch⁃blends composition quickly degradable in marine environment[J]. Journal of Polymers and the Environment, 2012, 21(3): 802⁃806. |

| 57 | Rutkowska M, Heimowska A, Krasowska K, et al. Biodegradability of polyethylene starch blends in sea water[J]. Polish Journal of Environmental Studies, 2002, 11(3): 267⁃271. |

| 58 | Guzman⁃Sielicka A, Janik H, Sielicki P. Degradation of polycaprolactone modified with TPS or CaCO3 in biotic/abiotic seawater[J]. Journal of Polymers and the Environment, 2011, 20(2): 353⁃360. |

| 59 | Wang X W, Wang G X, Huang D, et al. Degradability comparison of poly(butylene adipate terephthalate) and its composites filled with starch and calcium carbonate in different aquatic environments[J]. Journal of Applied Polymer Science, 2019, 136(2): 46916. |

| 60 | Huang Q, Kimura S, Iwata T. Thermal embedding of humicola insolens cutinase: A strategy for improving polyester biodegradation in seawater[J]. Biomacromolecules, 2023, 24(12): 5 836⁃5 846. |

| 61 | Huang D, Hu Z D, Ding Y, et al. Seawater degradable PVA/PCL blends with water⁃soluble polyvinyl alcohol as degradation accelerator[J]. Polymer Degradation and Stability, 2019, 163: 195⁃205. |

| 62 | Lu B, Zhen Z C, Liu T Y, et al. Rapid seawater⁃degradable PBSG/PVA blends: Easy water solubility and easy hydrolysis dual⁃promoting degradation[J]. Journal of Applied Polymer Science, 2022, 140(7): 53474. |

| 63 | Yoshikawa S, Katayama T, Kogure M, et al. Biodegradable resin composition, US 0184415[P].2013⁃07⁃18. |

| 64 | Tu Z, Wang B, Lu Y, et al. Incorporation of Large⁃Scale Prepared Poly(ethylene oxalate) into Biodegradable Poly(butylene adipate⁃co⁃terephthalate) Blown Films with Enhanced Mechanical and Barrier Performance[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(26): 9 833⁃9 845. |

| [1] | 冯硕, 周舒毅, 焦洋, 胡淼, 张若轩, 靳玉娟. 端环氧型超支化聚酯对聚乳酸/滑石粉复合材料性能的影响研究[J]. 中国塑料, 2025, 39(5): 36-42. |

| [2] | 谢世爽, 吴亮, 黄峰, 荣鑫, 湛玉舟, 李旭娟, 许向彬. 全生物降解膜在烤烟种植中的适应性及其对微生物多样性的影响[J]. 中国塑料, 2025, 39(3): 90-94. |

| [3] | 王兴国, 吕明福, 黄逸伦, 郭鹏, 高达利, 张师军. 聚乙醇酸高温降解性能研究及其调控方法[J]. 中国塑料, 2024, 38(8): 13-19. |

| [4] | 朱光泽, 夏志东, 周炜, 王晓露, 吴玉锋, 郭福. 聚酯漆包线漆与其热解产物的共热解行为研究[J]. 中国塑料, 2024, 38(8): 53-61. |

| [5] | 王珅, 刘宣伯, 张艳芳, 贾雪飞, 祝桂香, 张龙贵. 生物可降解无纺布材料研究进展[J]. 中国塑料, 2024, 38(7): 86-92. |

| [6] | 骆佳伟, 周炳, 王洪学, 贾钦. 扩链条件对聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯/滑石粉共混物性能的影响[J]. 中国塑料, 2024, 38(6): 1-11. |

| [7] | 李航, 杜玲枝, 吴晓林, 冯巧, 李桂丽. 酚醛⁃不饱和聚酯树脂石墨双极板复合材料研究[J]. 中国塑料, 2024, 38(10): 5-9. |

| [8] | 王泽辉, 王振军, 王笑风, 杨博, 李帅. 配方组成对聚氨酯注浆材料抗压强度影响的研究[J]. 中国塑料, 2023, 37(2): 7-14. |

| [9] | 张建忠, 方杨, 张旺斌, 黄腾, 俞友明, 戴进峰, 宋平安. 阻燃不饱和聚酯研究进展[J]. 中国塑料, 2023, 37(12): 115-123. |

| [10] | 杨洋, 韩宇, 翁云宣, 宋鑫宇, 黄志刚, 张彩丽. 环氧大豆油⁃癸二酸低分子量聚酯对PVC增塑性能的研究[J]. 中国塑料, 2023, 37(11): 87-94. |

| [11] | 刘昊育, 辛菲, 杜家盈, 樊晓玲. 无卤阻燃聚酯复合材料研究进展[J]. 中国塑料, 2023, 37(1): 133-143. |

| [12] | 黄嘉伟, 韩小龙, 吴悠, 靳玉娟, 王朝. 生物基工程聚酯弹性体对聚(3⁃羟基丁酸酯⁃co⁃3⁃羟基戊酸酯)的增韧改性研究[J]. 中国塑料, 2022, 36(9): 24-31. |

| [13] | 林健辉, 卢嘉慧, 吴欣颖, 范雪滢, 邓桂荣, 高亮, 梅承芳, 杨永刚. 受控堆肥条件下可降解材料最终需氧生物分解能力测定的不确定度评定研究[J]. 中国塑料, 2022, 36(9): 140-147. |

| [14] | 吴雄杰, 朱东波, 孙江波, 高龙美, 储雨, 程劲松, 谢爱迪. 聚乙烯/纳米硫酸钙粉体复合软包装应用性能研究[J]. 中国塑料, 2022, 36(6): 10-15. |

| [15] | 邵琳颖, 郗悦玮, 翁云宣. 可降解聚乳酸复合材料研究进展[J]. 中国塑料, 2022, 36(6): 155-164. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2