京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2022, Vol. 36 ›› Issue (4): 190-197.DOI: 10.19491/j.issn.1001-9278.2022.04.026

• Review • Previous Articles

PENG Bo, XIAO Yunbin, GU Jiabao, CHEN Zijun, TANG Yanhuang, ZHU Gang( ), XU Huanxiang(

), XU Huanxiang( )

)

Received:2021-10-18

Online:2022-04-26

Published:2022-04-24

CLC Number:

PENG Bo, XIAO Yunbin, GU Jiabao, CHEN Zijun, TANG Yanhuang, ZHU Gang, XU Huanxiang. Research progress in preparation and properties of polymer/graphene composites[J]. China Plastics, 2022, 36(4): 190-197.

| 1 | NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films [J]. Science, 2004, 306(5696): 666⁃669. |

| 2 | BALANDIN A A, GHOSH S, BAO W Z, et al. Superior thermal conductivity of single⁃layer graphene [J]. Nano Lett, 2008, 8(3): 902⁃907. |

| 3 | LEE C, WEI X D, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene [J]. Science, 2008, 321(5887): 385⁃388. |

| 4 | Lian H, Li S, Liu K, et al. Study on modified graphene/butyl rubber nanocomposites. I. preparation and characterization [J]. Polymer Engineering,2011, 51(11): 2 254⁃2 260. |

| 5 | KIM H, MACOSKO C W J P. Processing⁃property relationships of polycarbonate/graphene composites [J]. 2009, 50(15): 3 797⁃3 809. |

| 6 | ZHAN Y, WU J, XIA H, et al. Dispersion and exfoliation of graphene in rubber by an ultrasonically⁃assisted latex mixing and in situ reduction process [J]. Engineering,2011, 296(7): 590⁃602. |

| 7 | XIN W, YUAN H, LEI S, et al. In situ polymerization of graphene nanosheets and polyurethane with enhanced mechanical and thermal properties [J]. 2011, 21(21): 4 222⁃4 227. |

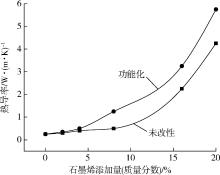

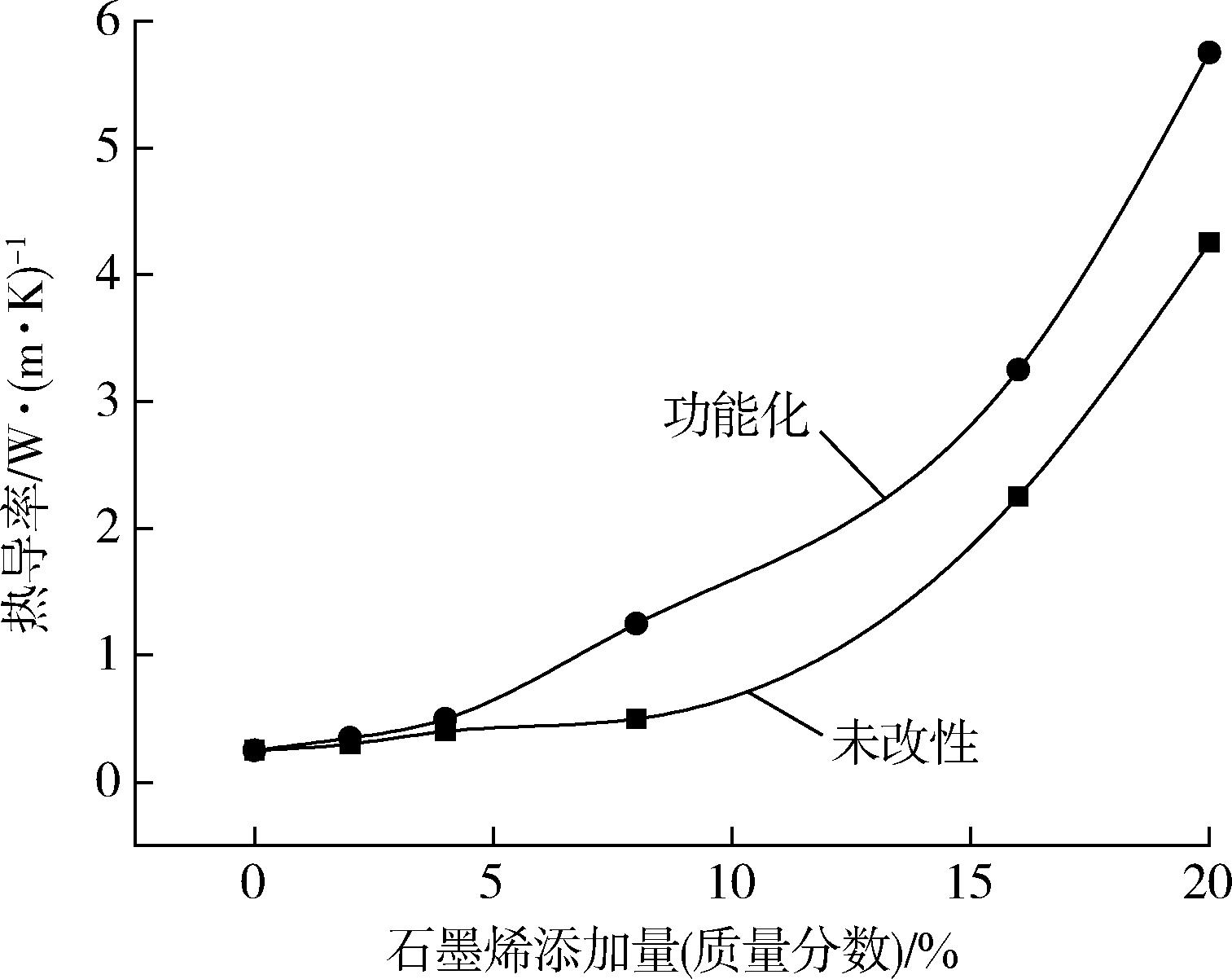

| 8 | KUILLA T, BHADRA S, YAO D H, et al. Recent advances in graphene based polymer composites [J]. Prog Polym Sci, 2010, 35(11): 1 350⁃1 375. |

| 9 | LI Y C, LI C Q, ZHAO S, et al. Facile fabrication of highly conductive and robust three⁃dimensional graphene/silver nanowires bicontinuous skeletons for electromagnetic interference shielding silicone rubber nanocomposites [J]. Compos Part A⁃Appl S, 2019, 119: 101⁃110. |

| 10 | SUN X Y, LIU X, SHEN X, et al. Graphene foam/carbon nanotube/poly(dimethyl siloxane) composites for exceptional microwave shielding [J]. Compos Part A⁃Appl S, 2016, 85: 199⁃206. |

| 11 | AO D Y, TANG Y L, XU X F, et al. Highly conductive pdms composite mechanically enhanced with 3D⁃graphene network for high⁃performance emi shielding application [J]. Nanomaterials⁃Basel, 2020, 10(4): 181⁃187. |

| 12 | TANG Z H, LIU X, HU Y M, et al. A slurry compounding route to disperse graphene oxide in rubber [J]. Mater Lett, 2017, 191: 93⁃96. |

| 13 | TIWARI A J D, GRADWORKS T. Graphene⁃based composite materials [J]. Nature,2011, 442(2): 282⁃286. |

| 14 | PHAM V H, DANG T T, HUR S H, et al. Highly conductive poly (methyl methacrylate)(pmma)⁃reduced graphene oxide composite prepared by self⁃assembly of pmma latex and graphene oxide through electrostatic interaction [J]. ACS Applied Materials & Interfaces, 2012, 4(5): 2 630⁃2 636. |

| 15 | STEURER P, WISSERT R, THOMANN R, et al. Functionalized graphenes and thermoplastic nanocomposites based upon expanded graphite oxide [J]. Macromolecular Rapid Communications, 2010, 30(4/5): 316⁃327. |

| 16 | ZONGPING C, WENCAI R, LIBO G, et al. Three⁃dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition [J]. Nature Materials, 2011, 10(6): 424. |

| 17 | LIU Y T, XIE X M, YE X Y J C. High⁃concentration organic solutions of poly(styrene⁃⁃butadiene⁃⁃styrene)⁃modified graphene sheets exfoliated from graphite [J]. Carbon,2011, 49(11): 3 529⁃3 537. |

| 18 | VADUKUMPULLY S, PAUL J, MAHANTA N, et al. Flexible conductive graphene/poly (vinyl chloride) composite thin films with high mechanical strength and thermal stability [J]. Carbon,2011, 49(1): 198⁃205. |

| 19 | KIM H, MIURA Y, MACOSKO C W J Co M. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity [J]. Chemistry of Materials, 2010, 22(11): 3 441⁃3 450. |

| 20 | SONG N, CAO D L, LUO X, et al. Highly thermally conductive polypropylene/graphene composites for thermal management [J]. Compos Part a⁃Appls, 2020:135. |

| 21 | GANGULI S, ROY A K, ANDERSON D P. Improved thermal conductivity for chemically functionalized exfoliated graphite/epoxy composites [J]. Carbon, 2008, 46(5): 806⁃817. |

| 22 | POTTS J R, SHANKAR O, MURALI S, et al. Latex and two⁃roll mill processing of thermally⁃exfoliated graphite oxide/natural rubber nanocomposites [J]. Composites Science and Technology, 2013, 74(4): 166⁃172. |

| 23 | YANG J, TIAN M, JIA Q X, et al. Improved mechanical and functional properties of elastomer/graphite nanocomposites prepared by latex compounding [J]. Acta Materialia, 2007, 55(18): 6 372⁃6 382. |

| 24 | VECA L M, MEZIANI M J, WEI W, et al. Carbon nanosheets for polymeric nanocomposites with high thermal conductivity [J]. Advanced Materials, 2010, 21(21): 2 088⁃2 092. |

| 25 | GHOSE S, WATSON K, DELOZIER D, et al. Thermal conductivity of ultem (trademark)/carbon nanofiller blends [J]. High Performance Polymers, 2006, 18(6): 961⁃977. |

| 26 | YU A, RAMESH P, SUN X, et al. Enhanced thermal conductivity in a hybrid graphite nanoplatelet⁃carbon nanotube filler for epoxy composites [J]. Advanced Materials, 2010, 20(24): 4 740⁃4 744. |

| 27 | SALAVAGIONE H J, MARTÍNEZ G, GÓMEZ M A. Synthesis of poly (vinyl alcohol)/reduced graphite oxide nanocomposites with improved thermal and electrical properties [J]. Journal of Materials Chemistry, 2009, 19(28): 5 027⁃5 032. |

| 28 | YU J, HUANG X, WU C, et al. Insulation E. Permittivity, thermal conductivity and thermal stability of poly(vinylidene fluoride)/graphene nanocomposites [J]. IEEE Transactions on Dielectrics and Electrical Insulation,2011, 18(2): 478⁃484. |

| 29 | COMPTON O C, SOYOUNG K, CYNTHIA P, et al.Crumpled graphene nanosheets as highly effective barrier property enhancers [J]. Advanced Materials,2010, 22(42): 4 759⁃4 763. |

| 30 | OZBAS B, O'NEILL C D, REGISTER R A, et al. Multifunctional elastomer nanocomposites with functionalized graphene single sheets [J]. Journal of Polymer Science Part B: Polymer Physics, 2012, 50(13): 910⁃916. |

| 31 | TAKASHI K, FANGMING D, DOUGLAS J F, et al. Nanoparticle networks reduce the flammability of polymer nanocomposites [J]. Nature Materials, 2005, 4(12): 928. |

| 32 | HIGGINBOTHAM A L, LOMEDA J R, MORGAN A B, et al. Graphite oxide flame⁃retardant polymer nanocomposites [J]. ACS Applied Materials & Interfaces, 2009, 1(10): 2 256⁃2 261. |

| 33 | KALAITZIDOU K, HIROYUKI D, LAWRENCE T J C. Multifunctional polypropylene composites produced by incorporation of exfoliated graphite nanoplatelets [J]. Carbon, 2007, 45(7): 1 446⁃1 452. |

| [1] | ZHU Zixuan, LIU Haifen, FAN Jiazhao, LI Huafeng, WANG Lixin. Research progress of adhesive materials and co⁃extrusion adhesion technology for photovoltaic backsheet [J]. China Plastics, 2022, 36(7): 174-186. |

| [2] | SONG Yinbao, YANG Jianjun, LI Chuanmin. Study on properties and manufacturing precision of PDMS/SiC functionally gradient composites [J]. China Plastics, 2022, 36(7): 30-36. |

| [3] | LIU Yi, SUN Wei, QU Guoxing, WANG Ye, YUAN Ning, YANG Shaolin, XU Xia, CHANG Xiaoyi, ZHANG Yufei. Structure and performance analysis of transparent polypropylene special material for thin⁃wall injection molding [J]. China Plastics, 2022, 36(7): 37-43. |

| [4] | GUO Yuwen, ZENG Bei, GAO Xing, WANG Pan, REN Lianhai. Effect of PET microplastics on performance of co⁃digestion of sewage sludges and food wastes [J]. China Plastics, 2022, 36(7): 51-60. |

| [5] | SONG Jin, XU Hang, ZOU Wei, WANG Hong, ZHANG Chen. Preparation and adsorption properties of surface⁃functionalized polyacrylate porous beads for Cu2+ [J]. China Plastics, 2022, 36(7): 8-13. |

| [6] | LI Kaize, XIN Yong. Properties of thermoplastic polyurethane composites modified with carbon nanotubes [J]. China Plastics, 2022, 36(6): 1-5. |

| [7] | WU Xiongjie, ZHU Dongbo, SUN Jiangbo, GAO Longmei, CHU Yu, CHENG Jinsong, XIE Aidi. Study on application performance of polyethylene/CaSO4 nanoparticle composite flexible packaging [J]. China Plastics, 2022, 36(6): 10-15. |

| [8] | SHAO Linying, XI Yuewei, WENG Yunxuan. Research progress in degradation characteristics of poly(lactic acid) composites [J]. China Plastics, 2022, 36(6): 155-164. |

| [9] | YANG Xiaolong, CHEN Wenjing, LI Yongqing, YAN Xiaokun, WANG Xiulei, XIE Pengcheng, MA Xiuqing. Research progress in polymer/graphene conductive composites [J]. China Plastics, 2022, 36(6): 165-173. |

| [10] | SUN Wenbo, XIN Chunling, HE Yadong, ZHAI Yujiao, YAN Baorui. Influence of micro⁃foaming injection molding process on cell structure of glass⁃fiber⁃reinforced PBT products [J]. China Plastics, 2022, 36(5): 1-7. |

| [11] | SUN Qi, GAO Xing, CUI Xuemei, LIAN Huiqin, CUI Xiuguo, WANG Xiaodong. Research progress in development and applications of black phosphorene for flame retardancy of polymers [J]. China Plastics, 2022, 36(5): 133-139. |

| [12] | WEI Liao. Research progress in application of water⁃soluble polymer materials for oil and gas field fracturing [J]. China Plastics, 2022, 36(5): 149-157. |

| [13] | WANG Ke, LONG Chunguang. Mechanical and tribological properties of ultra⁃high molecular weight polyethylene/sepiolite fiber composites [J]. China Plastics, 2022, 36(5): 19-23. |

| [14] | CHEN Sheng, LIANG Yingchao, WU Fangjuan, FANG Hui, FAN Xinfeng, CHEN Hui, WANG Yonggang. Preparation and interfacial modification of polyamide 6/bidirectional warp⁃knitted glass fiber composites [J]. China Plastics, 2022, 36(5): 24-28. |

| [15] | TIAN Chifeng, ZHANG Hongshen. Study on friction charge and high⁃voltage electrostatic separation of automotive polymer particles based on multi⁃fin friction bucket [J]. China Plastics, 2022, 36(5): 75-80. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||