京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2021, Vol. 35 ›› Issue (3): 151-160.DOI: 10.19491/j.issn.1001-9278.2021.03.020

• 综述 • 上一篇

祝问遥1,2, 邵伟光1, 王新华3, 李华1( ), 叶海木2, 蔡利海1

), 叶海木2, 蔡利海1

收稿日期:2020-07-19

出版日期:2021-03-26

发布日期:2021-03-22

ZHU Wenyao1,2, SHAO Weiguang1, WANG Xinhua3, LI Hua1( ), YE Haimu2, CAI Lihai1

), YE Haimu2, CAI Lihai1

Received:2020-07-19

Online:2021-03-26

Published:2021-03-22

Contact:

LI Hua

E-mail:lzmars@163.com

摘要:

分类总结了已有产业化耐高温电池隔膜材料的研究进展与制备工艺,着重介绍了采用不同涂覆材料与基体材料的传统与新型耐高温锂离子电池隔膜的耐热性能,并对耐高温锂离子电池隔膜材料进行了特点归纳与研究展望。

中图分类号:

祝问遥, 邵伟光, 王新华, 李华, 叶海木, 蔡利海. 耐高温锂离子电池隔膜材料应用现状及发展[J]. 中国塑料, 2021, 35(3): 151-160.

ZHU Wenyao, SHAO Weiguang, WANG Xinhua, LI Hua, YE Haimu, CAI Lihai. Application Status and Development of Heat Temperature⁃Resistant Separator Materials for Lithium⁃ion Batteries[J]. China Plastics, 2021, 35(3): 151-160.

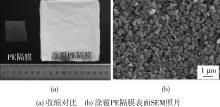

| 隔膜材料 | 耐热温度 | 制备工艺 | 特点 | 应用领域 | 生产厂商 |

|---|---|---|---|---|---|

| 聚烯烃 | 到达135 ℃闭孔,150 ℃完全熔毁 | 拉伸 | 耐热温度低,闭孔后有可能熔毁,但生产与加工工艺简单,成本低 | 商品电池 | Celgard(美国)、上海恩捷(中国) |

| 改性聚烯烃 | 142 ℃闭孔,170 ℃熔毁 | 涂覆 | 耐热温度较PE有略微提升,闭孔后不熔毁,生产加工工艺简单 | 商品电池 | 住友(日本)、 帝人(日本) |

| 玻璃纤维 | 400 ℃以上长期工作 | — | 耐热温度高,电能损耗率低,但价格过高 | 实验室电极性能测试 | Whatman(英国) |

| 芳纶 | 250 ℃以上长期工作,410 ℃熔融 | 涂布、热压、 静电纺丝 | 力学性能、耐热性能、电解液湿润性高,生产效率低,价格较PE昂贵 | 动力电池 | Dupont(美国)、东燃(日本) |

| 聚酰亚胺 | 600 ℃热分解,无熔融 | 静电纺丝 | 力学性能、耐热性能、电解液湿润性高,生产效率低,价格较PE昂贵 | 动力电池 | Dupont(美国) |

| 聚对苯二甲酸乙二醇酯 | 210 ℃下长期工作 | 热压、涂布 | 耐热性能良好,尺寸稳定,生产工艺简单 | 动力电池 | Degussa(德国) |

| 聚醚醚酮 | 370 ℃下低收缩率 | 静电纺丝 | 力学性能、耐热性能高生产工艺复杂 | 动力电池 | — |

| 隔膜材料 | 耐热温度 | 制备工艺 | 特点 | 应用领域 | 生产厂商 |

|---|---|---|---|---|---|

| 聚烯烃 | 到达135 ℃闭孔,150 ℃完全熔毁 | 拉伸 | 耐热温度低,闭孔后有可能熔毁,但生产与加工工艺简单,成本低 | 商品电池 | Celgard(美国)、上海恩捷(中国) |

| 改性聚烯烃 | 142 ℃闭孔,170 ℃熔毁 | 涂覆 | 耐热温度较PE有略微提升,闭孔后不熔毁,生产加工工艺简单 | 商品电池 | 住友(日本)、 帝人(日本) |

| 玻璃纤维 | 400 ℃以上长期工作 | — | 耐热温度高,电能损耗率低,但价格过高 | 实验室电极性能测试 | Whatman(英国) |

| 芳纶 | 250 ℃以上长期工作,410 ℃熔融 | 涂布、热压、 静电纺丝 | 力学性能、耐热性能、电解液湿润性高,生产效率低,价格较PE昂贵 | 动力电池 | Dupont(美国)、东燃(日本) |

| 聚酰亚胺 | 600 ℃热分解,无熔融 | 静电纺丝 | 力学性能、耐热性能、电解液湿润性高,生产效率低,价格较PE昂贵 | 动力电池 | Dupont(美国) |

| 聚对苯二甲酸乙二醇酯 | 210 ℃下长期工作 | 热压、涂布 | 耐热性能良好,尺寸稳定,生产工艺简单 | 动力电池 | Degussa(德国) |

| 聚醚醚酮 | 370 ℃下低收缩率 | 静电纺丝 | 力学性能、耐热性能高生产工艺复杂 | 动力电池 | — |

| 1 | HWANG K, KWON B, BYUN H. Preparation of PVDF Nanofiber Membranes by Electrospinning and Their Use as Secondary Battery Separators[J]. Journal of Membrane Science, 2011, 378(1/2):111⁃116. |

| 2 | ZHANG J, LIU Z, KONG Q, et al. Renewable and Superior Thermal⁃Resistant Cellulose⁃Based Composite Nonwoven as Lithium⁃ion Battery Separator[J]. ACS Applied Materials & Interfaces, 2013, 5(1):128⁃134. |

| 3 | 曹胜先. 锂离子电池隔膜研究与发展现状[J]. 塑料科技, 2013, 41(8):94⁃97. |

| CAO S X. Research and Development of Lithium⁃ion Battery Separators[J]. Plastics Science and Technology, 2013, 41(8):94⁃97. | |

| 4 | 洪柳婷, 王 莉, 叶海木,等. 聚烯烃锂离子电池隔膜的研究进展[J]. 高分子通报, 2017(6):59⁃67. |

| HONG L T,WANG L, YE H M,et al. Research Progress on Separators of Polyolefin Lithium Ion Battery[J]. Chinese Polymer Bulletin, 2017(6):59⁃67. | |

| 5 | 刘崇刚, 谭玲生, 史鹏飞. 锂离子电池的安全特性分析[J]. 电池工业, 2008, 13(2):78⁃81. |

| LIU C G, TAN L S, SHI P F. Study on The Safety Performance of Li⁃ion Batteries[J]. Chinese Battery Industry, 2008, 13(2):78⁃81. | |

| 6 | 李 贺, 于申军, 陈志奎,等. 锂离子电池内部短路失效的反应机理研究[J]. 电化学, 2010, 16(2):185⁃190. |

| LI H, YU S J, CHEN Z K, et al. Study on the Reaction Mechanism of Short Circuit Failure of Lithium Ion Battery[J]. Journal of Electrochemistry, 2010, 16(2):185⁃190. | |

| 7 | ZHENG H, QU Q, ZHANG L, et al. Hard Carbon a Promising Lithium⁃ion Battery Anode for High Temperature Applications with Ionic Electrolyte[J]. RSC Advances, 2012, 2(11):4 904. |

| 8 | ARUMUGAM D, KALAIGNAN G P. Electrochemical Characterizations of Surface Modified LiMn2O4 Cathode Materials for High Temperature Lithium Battery Applications[J]. Thin Solid Films, 2011, 520(1):338⁃343. |

| 9 | WANG J, WANG Y,GUO Y Z, et al. Electrochemical Characterization of AlPO4 Coated LiNi1/3Co1/3Mn1/3O2 Cathode Materials for High Temperature Lithium Battery Application[J]. Rare Metals, 2014:1⁃6. |

| 10 | ROBERTSON A D, WEST A R, RITCHIE A G. Review of Crystalline Lithium⁃ion Conductors Suitable For High Temperature Battery Applications[J]. Solid State Ionics, Diffusion & Reactions, 1997, 104(1⁃2):1⁃11. |

| 11 | 张 焱, 董浩宇, 刘杲珺,等. 动力锂离子电池复合隔膜研究进展[J]. 中国塑料, 2018, 32(5):15⁃27. |

| ZHANG Y, DONG H Y, LIU G J, et al. Research Progress in Composite Separators For Power Lithium Ion Battery[J]. China Plastics, 2018, 32(5):15⁃27. | |

| 12 | JIANG W, LIU Z, KONG Q, et al. A High Temperature Operating Nanofibrous Polyimide Separator in Li⁃ion Battery[J]. Solid State Ionics, 2013, 232:44⁃48. |

| 13 | 王海文, 怀永建, 潘文成,等. 不同工艺制备的锂离子电池用隔膜的热性能[J]. 电池, 2012, 42(1):30⁃32. |

| WANG H W, HUAI Y J, PAN W C, et al. Thermal Properties of Membranes for Lithium Ion Batteries Prepared by Different Processes[J]. Battery Bimonthly, 2012, 42(1):30⁃32. | |

| 14 | CHOI J W, AURBACH D. Promise and Reality of Post⁃Lithium⁃Ion Batteries with High Energy Densities[J]. Nature Reviews Materials, 2016, 1(4):1⁃16. |

| 15 | ARORA P, ZHANG Z. Battery Separators[J]. Chemical Reviews, 2004, 35(50):4 419⁃4 462. |

| 16 | 封志芳, 肖 勇, 温旭明,等. 锂离子电池隔膜技术研究进展[J]. 江西化工, 2019, 141(1):16⁃21. |

| FENG Z F, XIAO Y, WEN X M, et al. Research Progress of Separator Technology of Lithium Ion Battery[J]. Jiangxi Chemical Industry, 2019, 141(1):16⁃21. | |

| 17 | 宋建龙, 解华华, 刘 俊,等. 涂层改性锂离子电池隔膜研究进展[J]. 信息记录材料, 2015, 16(4):52⁃57. |

| SONG J L, XIE H H, LIU J, et al. Research Progress of Coating Modified Lithium Ion Battery Separators[J]. Information Recording Materials, 2015, 16(4):52⁃57. | |

| 18 | ZHANG X, JI L, TOPRAKCI O, et al. Electrospun Nanofiber⁃Based Anodes, Cathodes, and Separators for Advanced Lithium⁃Ion Batteries[J]. Polymer Reviews, 2011, 51(3):239⁃264. |

| 19 | AVDEEV I, MARTINSEN M, FRANCIS A. Rate⁃ and Temperature⁃Dependent Material Behavior of a Multilayer Polymer Battery Separator[J]. Journal of Materials Engineering and Performance, 2014, 23(1):315⁃325. |

| 20 | 莫名月, 陈红雨. 锂离子电池隔膜的研究进展[J]. 电源技术, 2011, 35(11):1 438⁃1 440. |

| MO M Y, CHEN H Y. Research Progress on Separator Materials for Lithium⁃ion Batteries[J]. Chinese Journal of Power Sources, 2011, 35(11):1 438⁃1 440. | |

| 21 | 黄友桥, 管道安. 锂离子电池隔膜材料的研究进展[J]. 船电技术, 2011, 31(1):26⁃29. |

| HUANG Y Q, GUAN D A. Recent Development of the Separator for Lithium Ion Battery[J]. Marine Electric Electronic Technology, 2011, 31(1):26⁃29. | |

| 22 | 君岛康太郎, 开米教充. 聚烯烃微多孔膜及其制造方法、以及电池用隔离件和电池:CN101313016 A[P]. 2011⁃09⁃28. |

| 23 | 菊地慎太郎, 泷田耕太郎. 聚烯烃多层微孔膜及其制造方法以及电池用隔离件:CN101296795 A[P]. 2008⁃10⁃29. |

| 24 | CHUNG Y S, YOO S H, KIM C K. Enhancement of Meltdown Temperature of the Polyethylene Lithium⁃Ion Battery Separator via Surface Coating with Polymers Having High Thermal Resistance[J]. Industrial & Engineering Chemistry Research, 2009, 48(9):4 346⁃4 351. |

| 25 | 温 敏, 巫晓鑫, 曾 钫,等. 锂电池隔膜母料用改性高密度聚乙烯的制备及性能研究[J]. 塑料工业, 2013, 41(9):118⁃121. |

| WEN M, WU X X, ZENG F, et al. Preparation and Performance of Cross⁃linking HDPE as Masterbatch for Lithium Battery Separator[J]. China Plastics Industry, 2013, 41(9):118⁃121. | |

| 26 | 程 跃, 陈 辉, 邓洪贵. 一种锂离子电池隔膜浆料及其制备方法和锂离子电池隔膜: CN 109585757 A[P]. 2019⁃04⁃05. |

| 27 | 程 跃, 张祖来, 苏晓明,等. 一种锂离子电池隔膜的制备方法: CN105552280A[P]. 2016⁃05⁃04 |

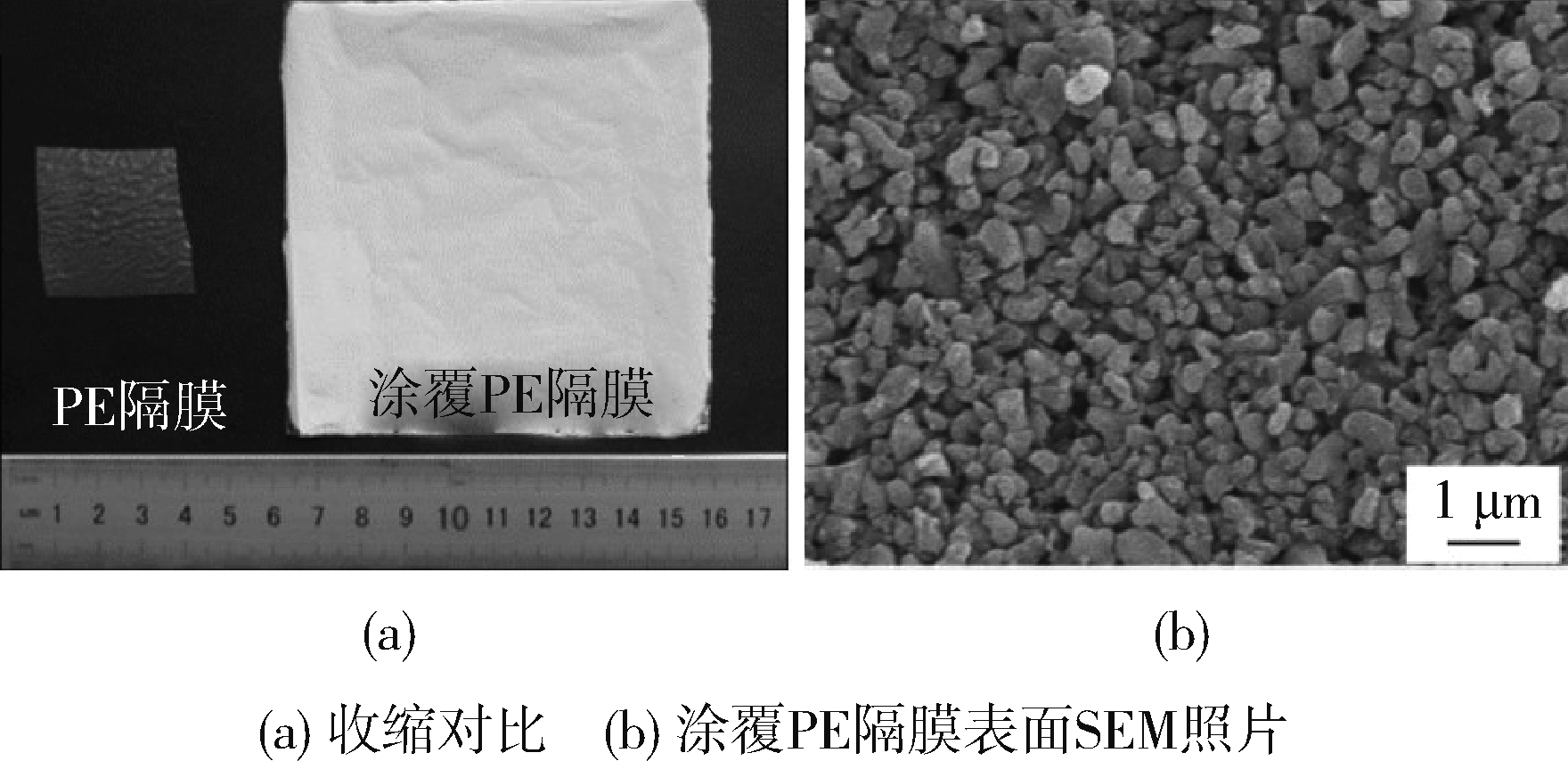

| 28 | 徐 健, 何林莉, 景希玮,等. 氧化铝/丙烯酸酯乳液改性聚乙烯隔膜的制备及性能[J]. 精细化工, 2019(7):1 321⁃1 325. |

| XU J, HE L L, JING X W, et al. Preparation and Properties of Al2O3/Acrylate Emulsion Modified Polyethylene Separators[J]. Fine Chemicals, 2019(7):1 321⁃1 325. | |

| 29 | LUI, CHRIS. Teijin Launches Fluorine⁃based Lithium⁃ion Battery Separators[N]. JCNN News Summaries⁃Japan Corporate News Network, 2012⁃02⁃07. |

| 30 | 樱井博志, 西川聪, 赤松哲也. 非水系二次电池用隔膜及非水系二次电池: CN109390533A[P]. 2019⁃02⁃26. |

| 31 | 住友化学锂离子电池隔膜产能将扩大2.3倍[J]. 信息记录材料, 2014(3):28. |

| 32 | 刘春娜. 锂电池隔膜行业发展动态[J]. 电源技术, 2015(4):657⁃658. |

| LIU C N. Development Trend of Lithium Battery Separator Industry[J]. Chinese Journal of Power Sources, 2015(4):657⁃658. | |

| 33 | 长谷川博彦, 西田裕纪, 筱原泰雄. 层叠多孔质膜及制造方法、非水电解液二次电池用隔膜、层叠电极片和非水电解液二次电池:CN109378428A[P]. 2019⁃02⁃22. |

| 34 | 尹艳红, 毛新欣, 曹朝霞,等. 相转化法制备陶瓷涂层改性锂离子电池隔膜[J]. 功能高分子学报, 2012, 25(2):69⁃74. |

| YIN Y H, MAO X X, CAO Z X, et al. Modification if Lithium Ion Battery Separator with Ceramic Coating Using Phase Invertion[J]. Journal of Functional Polymers, 2012, 25(2):69⁃74. | |

| 35 | 崔巍巍, 孟庆朋, 王振宇,等. 大倍率高耐热聚醚酰亚胺⁃聚偏氟乙烯芯壳纳米纤维锂离子电池隔膜[J]. 复合材料学报, 2019, 36(1):75⁃82. |

| CUI W W, MENG Q P, WANG Z Y, et al. A High Rate and Heat⁃resistant Polyether Imide⁃polyvinylidene Fluoride Core⁃shell Nanofiber Separator for Lithium⁃ion Battery[J]. Acta Materiae Compositae Sinica, 2019, 36(1):75⁃82. | |

| 36 | GONG W, GU J, RUAN S, et al. A High⁃strength Electrospun PPESK Fibrous Membrane for Lithium⁃ion Battery Separator[J]. Polymer Bulletin, 2019, 76(10):5 451⁃5 462. |

| 37 | 新材料在线.2020年锂电池隔膜行业研究报告[R/OL] [2020⁃07⁃18] ?id=575 605. |

| 38 | GUIDOTTI R A, REINHARDT F W. Evaluation of Fiber Separators for Use in Thermal Batteries[R]. Office of Scientific & Technical Information Technical Reports, 1999. |

| 39 | JIA H, STOCK C, KLOEPSCH R, et al. Facile Synthesis and Lithium Storage Properties of a Porous NiSi2/Si/carbon Composite Anode Material for Lithium⁃ion Batteries[J]. ACS Applied Materials & Interfaces, 2015, 7(3):1508. |

| 40 | ARAVINDAN V, KUMAR P S,SUNDARAMURTHY J, et al. Electrospun NiO Nanofibers as High Performance Anode Material for Li⁃ion Batteries[J]. Journal of Power Sources, 2013, 227(4):284⁃290. |

| 41 | WU Y, WANG F, LI X, et al. Fabrication of a Graphene Oxide/nanoscale Aramid Fiber Composite Membrane with Improved Hydrophilicity and Mechanical Strength via a Fast⁃drying Method Using Absolute Ethanol as Proton Donor[J]. Journal of Materials Science, 2018, 53(24): 16 383⁃16 392. |

| 42 | 杨 兵, 惠岚峰. 特种芳纶纤维在造纸中的应用[J]. 中华纸业, 2019(4):6⁃10. |

| YANG B, HUI L F. Application of Aramid Fiber in Specialty Paper Production[J]. China Pulp Paper Industry, 2019(4):6⁃10. | |

| 43 | 前瞻产业研究院. 2019年中国芳纶产品行业竞争格局与发展前景分析⁃中国间位芳纶市场未来发展可期[R/OL] [2020⁃07⁃09] . |

| 44 | 丁海兵. 对位芳纶国内外市场需求与产业化现状[J]. 合成纤维工业, 2013, 36(4):49⁃51. |

| DING H B. The Market Demand and Industrialization Status of Aramid Fiber at Home and Abroad[J]. China Synthetic Fiber Industry, 2013, 36(4):49⁃51. | |

| 45 | ZHANG J, KONG Q, LIU Z, et al. A Highly Safe and Inflame Retarding Aramid Lithium Ion Battery Separator by a Papermaking Process[J]. Solid State Ionics, 2013, 245: 49⁃55. |

| 46 | 陆赵情,张美云,王志杰,等. 芳纶纸基复合材料研究进展及关键技术[J]. 宇航材料工艺, 2006(6):5⁃8. |

| LU Z Q, ZHANG M Y, WANG Z J, et al. Progress and Technological Key of High Performance Aramid Paper Reinforced Composites[J]. Aerospace Materials Technology, 2006(6):5⁃8. | |

| 47 | 沢本敦司, 西原健太, 佃明光. 芳香族聚酰胺多孔膜、电池用隔膜及电池:CN104053714A[P]. 2014⁃09⁃07. |

| 48 | ZHANG J, KONG Q, LIU Z, et al. A Highly Safe and Inflame Retarding Aramid Lithium Ion Battery Separator by a Papermaking Process[J]. Solid State Ionics, 2013, 245:49⁃55. |

| 49 | LI J, TIAN W, YAN H, et al. Preparation and Performance of Aramid Nanofiber Membrane for Separator of Lithium Ion Battery[J]. Journal of Applied Polymer Science, 2016, 133(30):43623. |

| 50 | 何小芳, 韩雪鹏, 秦 刚,等. 聚酰亚胺(PI)锂离子电池隔膜材料的研究进展[J]. 塑料工业, 2016, 44(1):1⁃4. |

| HE X F, HAN X P, QIN G, et al. Research Progress of Polyimide Diaphragm Material for Lithium Ion Battery[J]. China Plastics Industry, 2016, 44(1):1⁃4. | |

| 51 | 安 平. 聚酰亚胺锂离子电池隔膜的制备及其性能研究[D]. 西安:陕西科技大学,2015. |

| 52 | 闫薪竹, 关士友. 锂离子电池用聚酰亚胺黏结剂和隔膜的制备及相关性能的研究[J]. 塑料工业, 2016, 44(8):125⁃128. |

| YAN X Z, GUAN S Y. Preparation and Properties of Polyimide Binder and Separator for Lithium Ion Battery[J]. China Plastics Industry, 2016, 44(8):125⁃128. | |

| 53 | 智研咨询.2017年全球聚酰亚胺行业产量统计分析[DB/OL][2020⁃07⁃09] . |

| 54 | 新材料在线.2019年聚酰亚胺(PI)行业研究报告[R/OL] [2020⁃07⁃09]?id=561861&ptype=1. |

| 55 | HUANG Z M, ZHANG Y Z, KOTAKI M, RAMAKRISHNA S. A Review on Polymer Nanofibers by Electrospinning and Their Applications in Nanocomposites[J]. Composites Science and Technology, 2003, 63(15): 2 223⁃2 253. |

| 56 | XUE J, WU T, DAI Y, et al. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications[J]. Chemical Reviews, 2019, 119(8): 5 298⁃5 415. |

| 57 | KIM Y, WU X, OH J H. Fabrication of Triboelectric Nanogenerators Based on Electrospun Polyimide Nanofibers Membrane[J]. Scientific Reports, 2020, 10(1): 1⁃9. |

| 58 | 王姝瑛, 李 敏, 龚光明,等. 静电纺丝制备具有浸润性梯度的聚酰亚胺纳米纤维膜[J]. 高等学校化学学报, 2012, 33(5): 1 090⁃1 094. |

| WANG S Y, LI M, GONG G M, et, al. Preparation of Polyimide Nanofiber Membrane with Gradient Wettability by Electrospinning [J]. Chemical Journal of Chinese Universities, 2012, 33(5): 1 090⁃1 094. | |

| 59 | 伯 章. 杜邦公司开发锂离子电池用聚酰亚胺隔膜[J]. 国外塑料, 2010, 28(9):67. |

| 60 | 丹尼斯T J,马祖尔S. 具有酰胺化表面的聚酰亚胺纳米纤维网及制备方法:CN103261502A[P]. 2016⁃01⁃13. |

| 61 | ZHAN J, TIAN G, QI S, et al. Fabrication and Mechanism Study of CuO Layers on Double Surfaces of Polyimide Substrate Using Surface Modification[J]. Composites Science and Technology, 2012, 72(9):1 020⁃1 026. |

| 62 | MIAO Y E, ZHU G N, Hou H, et al. Electrospun Polyimide Nanofiber⁃based Nonwoven Separators for Lithium⁃ion Batteries[J]. Journal of Power Sources, 2013, 226:82⁃86. |

| 63 | HAO J, LEI G, LI Z, et al. A Novel Polyethylene Terephthalate Nonwoven Separator Based on Electrospinning Technique for Lithium Ion Battery[J]. Journal of Membrane Science, 2013, 428:11⁃16. |

| 64 | 2018年中国非织造布市场发展现状及趋势分析[R/OL] [2020⁃07⁃09] . |

| 65 | XIA L, ZHANG Q, ZHUANG X, et al. Hot⁃pressed Wet⁃laid Polyethylene Terephthalate Nonwoven as Support for Separation Membranes[J]. Polymers, 2019, 11(10): 1 547. |

| 66 | KURIYAMA I, SHIRAKASHI K. Thermal Shrinkage Behavior of the Heated Polyethylene Terephthalate Fibers [J]. Sen'i Gakkaishi, 1964, 20(6): 347⁃355. |

| 67 | 王振华, 彭代冲, 孙克宁. 锂离子电池隔膜材料研究进展[J]. 化工学报, 2018, 69(1):282⁃294. |

| WANG Z H, PENG D C, SUN K N. Research Progress of Separator Materials for Lithium Ion Batteries[J]. CIESC Jorunal, 2018, 69(1):282⁃294. | |

| 68 | HENNIGE V, HYING C, HOERPEL G. Electrical Separator, Method for Making Same and Use Thereof in High⁃power Lithium Cells: US20050255769A1[P].2005⁃11⁃17. |

| 69 | ZHAO Z, WANG D, YU L, et al. Preparation and Property of High Heat⁃Resistant Ceramic Composited PET Separator[C]//Proceedings of SAE⁃China Congress 2014:Selected Papers:2014. |

| 70 | YE H M, ZHU W Y, LIU P, et al. Fabrication of Shrinkage⁃free Poly (Ether Ether Ketone) Nanofibrous Mat and Its Use For Flexible and Thermally⁃recycled MOF Composites[J]. Materials Today Communications, 2020, 23: 100862. |

| 71 | PATEL P, HULL T R, MCCABE R W, et al. Mechanism of Thermal Decomposition of Poly (Ether Ether Ketone)(PEEK) from a Review of Decomposition Studies[J]. Polymer Degradation and Stability, 2010, 95(5): 709⁃718. |

| 72 | SHUKLA D, NEGI Y S, UPPADHYAYA J S, et al. Synthesis and Modification of Poly (Ether Ether Ketone) and Their Properties: a Review[J]. Polymer Reviews, 2012, 52(2): 189⁃228. |

| 73 | 张 丽. 聚醚醚酮市场分析及发展趋势[J]. 化工新型材料, 2020, 48(5): 1⁃6. |

| ZHANG L. Analysis and Development Trend of PEEK Market[J]. New Chemical Materials, 2020, 48(5): 1⁃6. | |

| 74 | DEVAUX J,DELIMOY D, DAOUST D, et al. On the Molecular Weight Determination of a Poly (Aryl⁃ether⁃ether⁃ketone)(PEEK)[J]. Polymer, 1985, 26(13): 1 994⁃2 000. |

| 75 | LOVINGER A J, DAVIS D D. Solution Crystallization of Poly (Ether Ether Ketone)[J]. Macromolecules, 1986, 19(7): 1 861⁃1 867. |

| 76 | SHAM C K, GUERRA G, KARASZ F E, et al. Blends of Two Poly (Aryl Ether Ketones)[J]. Polymer, 1988, 29(6): 1 016⁃1 020. |

| 77 | XU J, ZHANG Z, XIONG X, et al. A New Solvent for Poly (Ether Ether Ketone)[J]. Polymer, 1992, 33(20): 4 432⁃4 434. |

| [1] | 冯凯, 李永青, 马秀清, 韩颖. 聚甲醛增韧改性的研究进展及应用[J]. 中国塑料, 2022, 36(7): 157-164. |

| [2] | 陈轲, 刘鸣飞, 赵彪, 潘凯. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154. |

| [3] | 邓天翔, 许利娜, 李守海, 张燕, 姚娜, 贾普友, 丁海阳, 李梅. PVC接枝改性及交联改性方法研究进展[J]. 中国塑料, 2022, 36(5): 140-148. |

| [4] | 王镕琛, 张恒, 孙焕惟, 段书霞, 秦子轩, 李晗, 朱斐超, 张一风. 医疗卫生用聚乳酸非织造材料的制备及其亲水改性研究进展[J]. 中国塑料, 2022, 36(5): 158-166. |

| [5] | 赵新新, 金晓冬, 施妍, 孙诗兵, 吕锋, 田英良, 赵志永. 基于紫外⁃臭氧辐照的挤塑聚苯乙烯表面改性研究[J]. 中国塑料, 2022, 36(5): 8-13. |

| [6] | 陈文静, 杨小龙, 韩顺涛, 韩颖, 马秀清. 聚丙烯腈材料改性方法及研究进展[J]. 中国塑料, 2022, 36(4): 158-165. |

| [7] | 董露茜, 徐芳, 翁云宣. 聚乙醇酸改性及其应用研究进展[J]. 中国塑料, 2022, 36(4): 166-174. |

| [8] | 李素圆, 刘会鹏, 龚舜, 黄国桃, 李玉才, 吴鑫, 邓建平, 潘凯. 热塑性聚酰胺弹性体改性EVA复合发泡材料的制备及性能表征[J]. 中国塑料, 2022, 36(4): 6-14. |

| [9] | 马嘉森, 薛永兵, 郭旗, 刘振民. 废旧塑料改性剂改性沥青的研究进展[J]. 中国塑料, 2022, 36(2): 131-138. |

| [10] | 仇洪波. 基于仿生学的木材超疏水表面改性研究进展[J]. 中国塑料, 2022, 36(2): 182-196. |

| [11] | 李永青, 杨小龙, 陈文静, 闫晓堃, 马秀清. 改性剂及高密度聚乙烯插层和剥离蒙脱石的分子动力学模拟[J]. 中国塑料, 2022, 36(2): 67-74. |

| [12] | 金福锦, 郝雨楠, 焦红文, 赵宏宇. 建筑绝热用石墨改性挤塑聚苯乙烯泡沫板的应用及标准解读[J]. 中国塑料, 2021, 35(9): 109-115. |

| [13] | 孙国华, 张信, 武德珍, 侯连龙. 高性能聚酰亚胺复合材料的研究进展[J]. 中国塑料, 2021, 35(9): 147-155. |

| [14] | 陆伟鑫, 陆冲, 王斌, 胡晶, 吴菁菁, 周秦鹏. 环氧改性剂对PA6/EVOH共混物性能的影响[J]. 中国塑料, 2021, 35(9): 8-14. |

| [15] | 黎帅, 龙春光, 闵建新, 周卓. 基于改性PET的极限PV值测试及摩擦学性能比较研究[J]. 中国塑料, 2021, 35(9): 87-94. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2