京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (7): 121-129.DOI: 10.19491/j.issn.1001-9278.2025.07.018

收稿日期:2024-07-10

出版日期:2025-07-26

发布日期:2025-07-22

通讯作者:

翁云宣(1972-),男,教授,研究方向为生物基材料及环境友好高分子材料,wyxuan@th.btbu.edu.cn作者简介:孙颖(1991-),女,实验员,研究方向为食品接触材料,btbusunying@163.com

基金资助:

SUN Ying1,2( ), BAI Lin1, WANG Rong3, WENG Yunxuan1,2(

), BAI Lin1, WANG Rong3, WENG Yunxuan1,2( )

)

Received:2024-07-10

Online:2025-07-26

Published:2025-07-22

Contact:

WENG Yunxuan

E-mail:btbusunying@163.com;wyxuan@th.btbu.edu.cn

摘要:

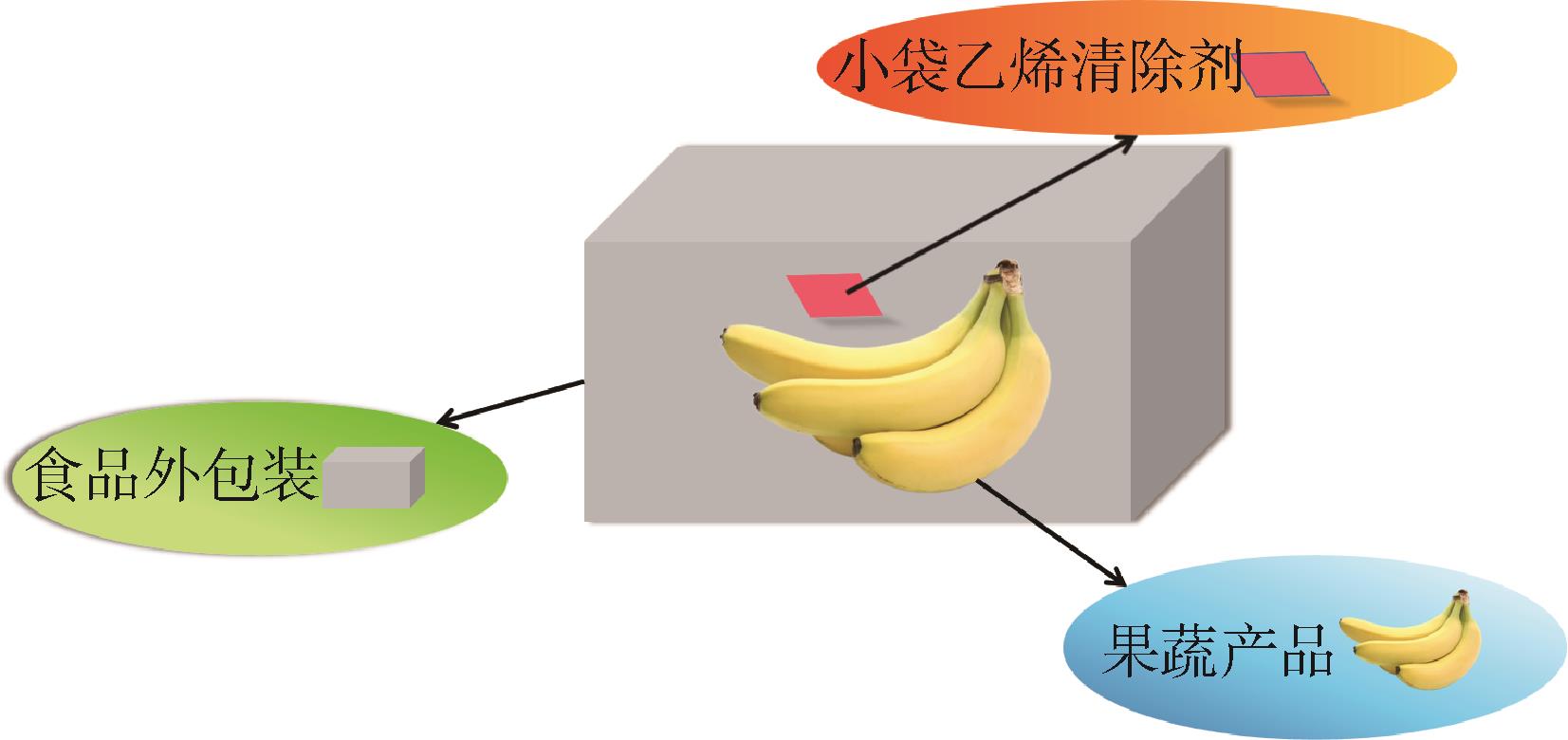

果蔬自身富含人体必需的营养物质,一直以来受到人们的青睐。然而果蔬采后由于其自身还会继续进行呼吸作用、蒸腾作用,在运输及保存过程中还会面临机械损伤和微生物污染的威胁,这些使得果蔬不易保存,极易腐烂变质,这造成了果蔬的极大浪费。果蔬保鲜便成了延长果蔬货架期、解决果蔬浪费的关键策略。在“双碳”目标及“限塑令”的大背景下,生物降解材料作为食品包装基材,实现食品保鲜的同时,还可缓解环境压力,因此成为了研究者们的研究热点。本文首先介绍了气调保鲜技术的原理,其次综述了可生物降解基材的分类以及它们所制备的包装形式与气调保鲜技术结合对果蔬保鲜的应用进展,最后对果蔬保鲜的未来发展前景进行了展望,以期为果蔬保鲜技术的进一步开发及实际应用提供理论参考。

中图分类号:

孙颖, 白林, 王蓉, 翁云宣. 基于生物聚酯材料的气调保鲜技术在果蔬质量安全领域的应用进展[J]. 中国塑料, 2025, 39(7): 121-129.

SUN Ying, BAI Lin, WANG Rong, WENG Yunxuan. Application progress of modified atmosphere packaging technology based on biopolyester materials in field of fruit/vegetable quality and safety[J]. China Plastics, 2025, 39(7): 121-129.

| 保鲜技术 | 优点 | 缺点 |

|---|---|---|

| 低温保鲜 | 低温下可以抑制微生物活性,降低果蔬呼吸强度,延缓果实衰老 | 温度过低会造成果实“冻伤” |

| 气调保鲜 | 对包装内部气体比例进行调节,降低果蔬呼吸速率,延长果蔬货架期 | 过高浓度的二氧化碳和过低浓度的氧气能促进果蔬代谢失常而使组织受到伤害,发生褐变、异味或腐烂。 |

| 辐照保鲜 | 消灭果蔬表面微生物,不会破坏果蔬外部形状,能够保持果实原有的营养成分以及颜色、味道 | 辐射会对食物的营养质量产生不利影响,高能辐射会分解破坏维生素和矿物质的营养物质。辐照处理单元中的辐射可能对工人有害。 |

| 防腐剂保鲜 | 减缓果蔬后熟过程,降低果实的呼吸速率,具有操作简单、使用成本低、设备投资小 | 防腐剂的存在会威胁人类身体健康,具有一定的食品安全隐患 |

| 保鲜技术 | 优点 | 缺点 |

|---|---|---|

| 低温保鲜 | 低温下可以抑制微生物活性,降低果蔬呼吸强度,延缓果实衰老 | 温度过低会造成果实“冻伤” |

| 气调保鲜 | 对包装内部气体比例进行调节,降低果蔬呼吸速率,延长果蔬货架期 | 过高浓度的二氧化碳和过低浓度的氧气能促进果蔬代谢失常而使组织受到伤害,发生褐变、异味或腐烂。 |

| 辐照保鲜 | 消灭果蔬表面微生物,不会破坏果蔬外部形状,能够保持果实原有的营养成分以及颜色、味道 | 辐射会对食物的营养质量产生不利影响,高能辐射会分解破坏维生素和矿物质的营养物质。辐照处理单元中的辐射可能对工人有害。 |

| 防腐剂保鲜 | 减缓果蔬后熟过程,降低果实的呼吸速率,具有操作简单、使用成本低、设备投资小 | 防腐剂的存在会威胁人类身体健康,具有一定的食品安全隐患 |

| 类别 | 气体比例 | 包装基材 | 果蔬种类 | 保鲜效果 | 参考文献 |

|---|---|---|---|---|---|

| 主动气调 | 5 %O2、5 %CO2 | 聚乳酸(PLA) | 鲜切油桃 | 有效降低了果实失重率,延长了鲜切油桃的货架期 | [ |

| 15 %~17 %O2、2 %~5 %CO2 | - | 黄瓜 | 微穿孔包装将黄瓜的保质期延长了至少22天,并将黄瓜保质期延长了5天以上 | [ | |

| 1.2 %~1.9 % O2、5.13 %~5.2 % CO2、 | PLA | 芒果 | 延缓了果肉的黄变和生化特性,在低温下保持了芒果的硬度、水分含量以及品质,延长保质期至30 d | [ | |

| 13 %O2、4 %~6 %CO2 | PCL | 番茄 | 延长了在冷藏温度下储存的番茄的保质期、延缓了其颜色变化,降低了番茄的营养成分流失和腐烂率 | [ | |

| 被动气调 | 2 %~3 %O2、7 %~8 %CO2 | PLA | 鲜切甜瓜 | 甜瓜的货架期延长至11天 | [ |

| - | 淀粉 | 蓝莓 | 延长蓝莓货架期至15天,保持了蓝莓的营养价值 | [ | |

| 3 %~5 %O2、5 %~7 %CO2 | PLA | 草莓 | 短时间达到理想气体比例,减少草莓营养物质的流失和质量损失 | [ | |

| 3.7 %O2、4.3 %CO2 | PLA | 樱桃番茄 | 气调薄膜的成本降低一半,延长樱桃番茄的保鲜期至28天 | [ | |

| 0.48 %~0.66 %O2、5.98 % ~6.53 %CO2 | PBAT | 沙葱 | 保持沙葱的维生素C含量、叶绿素含量及其形态、色泽,具有较高水平的市场可接受度 | [ | |

| 3 %~5 %O2、1.8 %~3.8 %CO2 | PBAT/聚丁二酸丁二醇酯(PBS) | 樱桃番茄 | CO2和O2的浓度始终稳定在适宜保鲜樱桃番茄的气氛范围内, 有效地抑制了樱桃番茄的腐败变质, 维持了其较好的感官品质和营养价值 | [ |

| 类别 | 气体比例 | 包装基材 | 果蔬种类 | 保鲜效果 | 参考文献 |

|---|---|---|---|---|---|

| 主动气调 | 5 %O2、5 %CO2 | 聚乳酸(PLA) | 鲜切油桃 | 有效降低了果实失重率,延长了鲜切油桃的货架期 | [ |

| 15 %~17 %O2、2 %~5 %CO2 | - | 黄瓜 | 微穿孔包装将黄瓜的保质期延长了至少22天,并将黄瓜保质期延长了5天以上 | [ | |

| 1.2 %~1.9 % O2、5.13 %~5.2 % CO2、 | PLA | 芒果 | 延缓了果肉的黄变和生化特性,在低温下保持了芒果的硬度、水分含量以及品质,延长保质期至30 d | [ | |

| 13 %O2、4 %~6 %CO2 | PCL | 番茄 | 延长了在冷藏温度下储存的番茄的保质期、延缓了其颜色变化,降低了番茄的营养成分流失和腐烂率 | [ | |

| 被动气调 | 2 %~3 %O2、7 %~8 %CO2 | PLA | 鲜切甜瓜 | 甜瓜的货架期延长至11天 | [ |

| - | 淀粉 | 蓝莓 | 延长蓝莓货架期至15天,保持了蓝莓的营养价值 | [ | |

| 3 %~5 %O2、5 %~7 %CO2 | PLA | 草莓 | 短时间达到理想气体比例,减少草莓营养物质的流失和质量损失 | [ | |

| 3.7 %O2、4.3 %CO2 | PLA | 樱桃番茄 | 气调薄膜的成本降低一半,延长樱桃番茄的保鲜期至28天 | [ | |

| 0.48 %~0.66 %O2、5.98 % ~6.53 %CO2 | PBAT | 沙葱 | 保持沙葱的维生素C含量、叶绿素含量及其形态、色泽,具有较高水平的市场可接受度 | [ | |

| 3 %~5 %O2、1.8 %~3.8 %CO2 | PBAT/聚丁二酸丁二醇酯(PBS) | 樱桃番茄 | CO2和O2的浓度始终稳定在适宜保鲜樱桃番茄的气氛范围内, 有效地抑制了樱桃番茄的腐败变质, 维持了其较好的感官品质和营养价值 | [ |

| [1] | GOGO E O, OPIYO A M, HASSENBERG K, et al. Postharvest UV⁃C treatment for extending shelf life and improving nutritional quality of African indigenous leafy vegetables[J]. Postharvest Biology and Technology, 2017,129:107⁃117. |

| [2] | 马修钰, 王建清, 王玉峰,等. 果蔬保鲜方法概述[J]. 中国果菜, 2016,36(6):4⁃9. |

| MA X Y, WANG J Q, WANG Y F, et al. Overview of preservation methods for fruits and vegetables[J]. Chinese Fruit and Vegetable, 2016,36 (6): 4⁃9. | |

| [3] | 黄佳丽, 庞 燕, 王忠伟. “双碳”目标下的果蔬产品冷链协调优化[J]. 中南林业科技大学学报, 2023,43(3):187⁃196. |

| HUANG J L, PANG Y, WANG Z W. Coordination and optimization of the cold chain system of fruit and vegetable products under dual carbon target[J]. Journal of Central South University of Forestry & Technology, 2023,43(3):187⁃196. | |

| [4] | 张 鹏, 朱文月, 李江阔, 等. 微环境气体调控在果蔬保鲜中的研究进展[J]. 包装工程, 2020. 41(1):1⁃10+239. |

| ZHANG P, ZHU W Y, LI J K, et al. Research progress on microenvironmental gas regulation in fruit and vegetable preservation[J]. Packaging Engineering, 2020,41 (1): 1⁃10+239. | |

| [5] | GOVE J M, WHITNEY J L, MCMANUS M A, et al. Prey⁃size plastics are invading larval fish nurseries[J]. PNAS, 2019,116(48):24 143⁃24 149. |

| [6] | NIAN LINYU, WANG MENGJUN, SUN XIAOYANG, et al. Biodegradable active packaging: components, preparation, and applications in the preservation of postharvest perishable fruits and vegetables[J]. Critical Reviews in Food Science and Nutrition, 2024,64(8):2 304⁃2 339. |

| [7] | 程 昊, 陈 龙, 徐振林, 等. 天然可降解材料的研究进展[J]. 食品安全质量检测学报, 2023,14(11):205⁃213. |

| CHENG H, CHEN L, XU Z L, et al. Research progress in natural degradable materials[J]. Journal of Food Safety and Quality Testing, 2023,14 (11): 205⁃213. | |

| [8] | CHEN W Z, MA S B, WANG Q K, et al. Fortification of edible films with bioactive agents: a review of their formation, properties, and application in food preservation[J]. Critical Reviews in Food Science and Nutrition, 2022,62(18):5 029⁃5 055. |

| [9] | CAZON P, VELAZQUEZ G, RAMIREZ J A, et al. Polysaccharide⁃based films and coatings for food packaging: a review[J]. Food Hydrocolloids, 2017,68:136⁃148. |

| [10] | AGARWAL S, SINGHAL S, GODIYA C B, et al. Prospects and applications of starch based biopolymers[J]. International Journal of Environmental Analytical Chemistry, 2023, 103(18): 6 907⁃6 926. |

| [11] | ZOU Y Y, YUAN C, CUI B, et al. Formation of high amylose corn starch/konjac glucomannan composite film with improved mechanical and barrier properties[J]. Carbohydrate Polymers, 2021,251:117039. |

| [12] | GOUDARZI V, SHAHABI⁃GHAHFARROKHI I, BABAEI⁃GHAZVINI A. Preparation of ecofriendly UV⁃protective food packaging material by starch/TiO2 bio⁃nanocomposite: Characterization[J]. International Journal of Biological Macromolecules, 2017,95:306⁃313. |

| [13] | HUANG X, ZHOU X, DAI Q Y, et al. Antibacterial, antioxidation, UV⁃blocking, and biodegradable soy protein isolate food packaging film with mangosteen peel extract and ZnO nanoparticles[J]. Nanomaterials, 2021,11(12): 3 337. |

| [14] | MOHAMED SAA, EL⁃SAKHAWY M, EL⁃SAKHAWY MAM. Polysaccharides, protein and lipid⁃based natural edible films in food packaging: a review[J]. Carbohydrate Polymers, 2020,238: 116178. |

| [15] | AMIN U, KHAN MU, MAJEED Y, et al. Potentials of polysaccharides, lipids and proteins in biodegradable food packaging applications[J]. International Journal of Biological Macromolecules, 2021,183:2 184⁃2 198. |

| [16] | NIAN L Y, WANG M J, WANG F F, et al. Multifunctional material Cer@MHKUST-1 with efficient preservation capability[J]. Chemical Engineering Journal, 2022,433: 133267. |

| [17] | YUAN Y, HE N, XUE Q R, et al. Shellac: a promising natural polymer in the food industry[J]. Trends in Food Science and Technology, 2021,109:139⁃153. |

| [18] | SORADECH S, NUNTHANID J, LIMMATVAPIRAT S, et al. Utilization of shellac and gelatin composite film for coating to extend the shelf life of banana[J]. Food Control, 2017,73:1 310⁃1 317. |

| [19] | 胡预龙, 张如强, 李文俊, 等 生物可降解食品包装材料的研究进展 [J]. 精细化工, 2025,42(6):1 211⁃1 220. |

| HU Y L, ZHANG R Q, LI W J, et al. Research progress on biodegradable food packaging materials[J]. Fine Chemicals, 2025,42(6):1 211⁃1 220. | |

| [20] | RUSKOVA M, SISKOVA A O, MOSNACKOVA K, et al. Biodegradable active packaging enriched with essential oils for enhancing the shelf life of strawberries[J]. Antioxidants, 2023,12(3): 755. |

| [21] | 吴雨纯, 袁璐璐, 常广谦, 等. 木质素/PBAT复合材料的性能提升与应用研究进展[J]. 中国造纸, 2024,43(4): 10⁃24. |

| WU Y C, YUAN L L, CHANG G Q, et al. Progress in the performance improvement and applications of lignin/PBAT compo⁃sites[J]. China Pulp & Paper, 2024,43(4): 10⁃24. | |

| [22] | ZHANG C H, CHEN F P, MENG W, et al. Polyurethane prepolymer⁃modified high⁃content starch⁃PBAT films[J]. Carbohydrate Polymers, 2021,253: 117 168. |

| [23] | PHOTHISARATTANA D, WONGPHAN P, PROMHUAD K, et al. Biodegradable poly(butylene adipate⁃co⁃terephthalate) and thermoplastic starch⁃Blended TiO2 nanocomposite blown films as functional active packaging of fresh fruit[J]. Polymers, 2021,13(23): 4 192. |

| [24] | NGUYEN S V, LEE B K. PVA/CNC/TiO2 nanocomposite for food⁃packaging: improved mechanical, UV/water vapor barrier, and antimicrobial properties[J]. Carbohydrate Polymers, 2022,298: 120064. |

| [25] | 何 伟. 果蔬气调保鲜技术及其在冷链物流中的应用研究进展[J]. 食品与机械, 2020,36(9):228⁃232. |

| HE W. Research progress on modified atmosphere preservation technology for fruits and vegetables and its application in cold chain logistics[J]. Food and Machinery, 2020,36 (9): 228⁃232. | |

| [26] | 郭风军, 张长峰, 姜沛宏, 等. 果蔬保鲜包装技术及其研究进展[J]. 保鲜与加工, 2019, 19(6):197⁃203+210. |

| GUO F J, ZHANG C F, JIANG P H, et al. Fruit and vegetable preservation packaging technology and its research progress[J]. Preservation and Processing, 2019,19 (6): 197⁃203+210. | |

| [27] | 潘玉军, 付秋莹. 气调包装延长果蔬贮存期的研究进展[J]. 今日印刷, 2018(10):61⁃64. |

| PAN Y J, FU Q Y. Research progress on extending the storage life of fruits and vegetables through modified atmosphere packaging[J]. Printed Today, 2018 (10): 61⁃64. | |

| [28] | MAGHENZANi M, CHIABRANDO V, GIACALONE G. The effect of different MAP on quality retention of fresh⁃cut nectarines[J]. International Food Research Journal, 2016,23(5):1 872⁃1 878. |

| [29] | OWOYEMI A, PORAT R, RODOV V. Effects of compostable packaging and perforation rates on cucumber quality during extended shelf life and simulated farm⁃to⁃fork supply⁃chain conditions[J]. Foods, 2021,10(2): 471. |

| [30] | YUANYUE WU, KAIJUN XIAO, LIANG ZHU, et al. Preparation and application of equilibrium modified atmosphere packaging membranes with polylactic acid and polymers of intrinsic microporosity[J]. Food Packaging and Shelf Life, 2023,37: 101063. |

| [31] | YUN X Y, QI X J, ZHANG Y Q, et al. Application of SiO (x) ⁃coated poly (epsilon⁃caprolactone) film for preservation of cherry tomato[J]. Polymers and Polymer Composites, 2020,28(5):309⁃319. |

| [32] | MORGADO CMA, SALLANON H, MATTIUZ BH, et al. Heat treatment and active packaging to improve the storage of fresh⁃cut melons (Cucumis melo L.)[J]. Fruits, 2016, 71(1):9⁃15. |

| [33] | GIUGGIOLI N R, GIRGENTI V, PEANO C. Qualitative performance and consumer acceptability of starch films for the blueberry modified atmosphere packaging storage[J]. Polish Journal of Food and Nutrition Sciences, 2017,67(2):129⁃136. |

| [34] | 赵文波. 聚乳酸/中空介孔二氧化硅微球复合膜的制备及其对草莓保鲜效果研究[D]. 内蒙古: 内蒙古农业大学, 2022. |

| [35] | 刘 博. 柔性聚乳酸薄膜的制备及其在樱桃番茄气调保鲜中的应用[D]. 内蒙古:内蒙古农业大学, 2022. |

| [36] | 卜红宇. PBAT基气调呼吸膜对沙葱的保鲜效果及保鲜机理研究[D]. 内蒙古:内蒙古农业大学, 2021. |

| [37] | 刘孟禹, 钱玉娇, 张敏欢, 等. 改性PBS薄膜对樱桃番茄的自发气调保鲜效果[J]. 食品工业, 2019,40(8): 169⁃174. |

| LIU M Y, QIAN Y J, ZHANG M H, et al. The spontaneous controlled atmosphere preservation effect of modified PBS film on cherry tomatoes[J]. Food Industry, 2019,40 (8): 169⁃174. | |

| [38] | PEANO C, GIUGGIOLI NR, GIRGENTI V. Effects of innovative packaging materials on apricot fruits (cv Tom Cot (R))[J]. Fruits, 2014,69(3):247⁃258. |

| [39] | KIM D, SEO J. A review: breathable films for packaging applications[J]. Trends in Food Science and Technology, 2018,76:15⁃27. |

| [40] | GIANNOULIS A, MISTRIOTIS A, BRIASSOULIS D. 3D numerical simulations as optimization tool for the design of novel EMAP systems[J]. Computers and Electronics in Agriculture, 2017,143:119⁃129. |

| [41] | ZHOU Z Q, MA J J, LI K, et al. A plant leaf⁃mimetic membrane with controllable gas permeation for efficient preservation of perishable products[J]. ACS Nano, 2021,15(5):8 742⁃8 752. |

| [42] | HELLAND H S, LEUFVEN A, BENGTSSON G B, et al. Storage of fresh⁃cut swede and turnip in modified atmosphere: effects on vitamin C, sugars, glucosinolates and sensory attributes[J]. Postharvest Biology and Technology, 2016,111:150⁃160. |

| [43] | SARFRAZ J, HANSEN A A, HAUGEN J E, et al. Biodegradable active packaging as an alternative to conventional packaging: a case study with chicken fillets[J]. Foods, 2021,10(5): 1 126. |

| [44] | CHEN M L, YAN X R, CHENG M, et al. Preparation, characterization and application of poly(lactic acid)/corn starch/eucalyptus leaf essential oil microencapsulated active bilayer degradable film[J]. International Journal of Biological Macromolecules, 2022,195:264⁃273. |

| [45] | ADAY M S, CANER C. The shelf life extension of fresh strawberries using an oxygen absorber in the biobased package[J]. Lwt⁃Food Science Technology, 2013,52(2):102⁃109. |

| [46] | LEE D S. Carbon dioxide absorbers for food packaging applications[J]. Trends in Food Science and Technology, 2016,57:146⁃155. |

| [47] | 马玉婷, 王瑞环. 水果保鲜技术研究进展[J]. 山东化工, 2020, 49(20):48⁃49. |

| MA Y T, WANG R H. Research progress in fruit preservation technology[J]. Shandong Chemical Industry, 2020,49 (20):48⁃49. | |

| [48] | 千春录, 林 晨, 殷健东, 等. 1⁃MCP和自发气调对猕猴桃果实贮藏品质和色素的影响[J]. 江苏农业科学, 2018,46(13):189⁃192. |

| QIAN C L, LIN C, YIN J D, et al. The effects of 1⁃MCP and spontaneous controlled atmosphere on the storage quality and pigments of kiwifruit[J]. Agricultural Science, 2018 46(13): 189⁃192. | |

| [49] | MATIACEVICH S, ACEVEDO N, LÓPEZ D. Characterization of edible active coating based on alginate⁃thyme oil⁃propionic acid for the preservation of fresh chicken breast fillets[J]. Journal of Food Processing and Preservation, 2015,39(6):2 792⁃2 801. |

| [50] | FALGUERA V, QUINTERO J P, JIMÉNEZ A, et al. Edible films and coatings: structures, active functions and trends in their use[J]. Trends in Food Science & Technology, 2011,22(6):292⁃303. |

| [51] | JU J, XIE Y F, GUO Y H, et al. Application of edible coating with essential oil in food preservation[J]. Critical Reviews in Food Science and Nutrition, 2019,59(15):2 467⁃2 480. |

| [52] | PEREZ D A, GOMEZ J M, CASTELLANOS D A. Combined modified atmosphere packaging and guar gum edible coatings to preserve blackberry (Rubus glaucusBenth)[J]. Food Science and Technology International, 2021,27(4):353⁃365. |

| [53] | 濮艳清. 鲜切果蔬高品质短期保鲜包装工艺研究[D]. 无锡:江南大学,2020 . |

| [54] | LU LU, XIAOYING LI, JUN H E, et al. Effect of modified atmosphere packaging on the preservation quality of fresh wolfberry[J]. Food Industry, 2021(7):168⁃172. |

| [55] | KAWINCHAYA SAIKAEW, WILAILAK SIRIPORNADULSIL, SURASAK SIRIPORNADULSIL. Calcium chloride and chitosan coatings combined with modified atmosphere packaging extend the shelf life and maintain the quality of frozen mango slices[J]. International Journal of Food Science & Technology, 2023,58(3):1 162⁃1 175. |

| [1] | 冯硕, 林小淇, 朱艳丽, 高维常, 翁云宣, 张彩丽. 生物降解塑料PBAT的化学回收与生命周期评价:现状、挑战与前景[J]. 中国塑料, 2025, 39(7): 102-111. |

| [2] | 杨晴, 蔡加锋, 顾卫华, 彭圣娟, 赵静, 白建峰. 生物降解法对塑料废物可持续管理的研究进展[J]. 中国塑料, 2025, 39(5): 88-94. |

| [3] | 荣鑫, 李向鹏, 吴亮, 李旭娟, 许向彬. 生物降解膜在重庆涪陵地区烟草种植中的应用研究[J]. 中国塑料, 2025, 39(4): 64-68. |

| [4] | 储星宇, 方芳, 徐润泽, 王苏娜, 操家顺. 聚羟基脂肪酸酯在不同条件下的生物降解研究进展[J]. 中国塑料, 2025, 39(4): 84-91. |

| [5] | 谢世爽, 吴亮, 黄峰, 荣鑫, 湛玉舟, 李旭娟, 许向彬. 全生物降解膜在烤烟种植中的适应性及其对微生物多样性的影响[J]. 中国塑料, 2025, 39(3): 90-94. |

| [6] | 高成涛, 胥秋, 张黎, 李剑, 黄维, 陈劲松, 刘楠, 何声宝, 陈思瑶, 潘首慧. 无机纳米粒子在可生物降解复合材料中的应用进展[J]. 中国塑料, 2025, 39(1): 85-91. |

| [7] | 陈卓, 胡婕, 马超, 李晓慧, 班甜甜, 刘小翠. 贵州地形及气候条件下生物降解地膜对白菜产量、土壤环境和经济效益的影响[J]. 中国塑料, 2025, 39(1): 97-103. |

| [8] | 崔豹, 杨建军, 吴庆云, 吴明元, 张建安, 刘久逸. 聚乳酸复合材料共混改性研究及应用进展[J]. 中国塑料, 2024, 38(9): 129-136. |

| [9] | 殷茂峰, 王晓珂, 孙国华, 张信, 李鹏鹏, 马劲松, 肖军, 侯连龙. 红外光谱快速检测生物降解聚酯的研究[J]. 中国塑料, 2024, 38(9): 94-100. |

| [10] | 骆佳伟, 周炳, 王洪学, 贾钦. 扩链条件对聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯/滑石粉共混物性能的影响[J]. 中国塑料, 2024, 38(6): 1-11. |

| [11] | 孟凡悦, 文悦, 李琛, 高珊. 生物基塑料包装需氧生物降解研究进展[J]. 中国塑料, 2024, 38(4): 109-115. |

| [12] | 郭志豪, 冯涛, 李字义, 王晶, 王冰, 王艺翰, 曹博为. 塑料降解测试中塑料混合物湿度的变化规律[J]. 中国塑料, 2024, 38(3): 94-100. |

| [13] | 王梓丞, 杨彪. 生物降解阻隔材料的研究进展[J]. 中国塑料, 2023, 37(12): 124-134. |

| [14] | 孙文潇, 杨帆, 侯梦宗, 贺丹丹, 吴慧, 刘强, 张宏. 环境中的微塑料污染及降解[J]. 中国塑料, 2023, 37(11): 117-126. |

| [15] | 马志蕊, 尹甜, 蒋志魁, 杨璠, 祝孟珂, 杨洋, 韩宇, 翁云宣, 张彩丽. PBS及其复合膜的制备及应用研究进展[J]. 中国塑料, 2023, 37(10): 24-33. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2