京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2020, Vol. 34 ›› Issue (10): 100-109.DOI: 10.19491/j.issn.1001-9278.2020.10.017

收稿日期:2020-08-03

出版日期:2020-10-26

发布日期:2020-10-26

基金资助:

WEI Shiyi, TANG Yuntao, CHAI Chenze, ZHANG Yuxia( ), ZHOU Hongfu

), ZHOU Hongfu

Received:2020-08-03

Online:2020-10-26

Published:2020-10-26

Contact:

ZHANG Yuxia

E-mail:zhangyux@th.btbu.edu.cn

摘要:

综述了改性聚乳酸(PLA)开孔材料的研究进展,包括可生物降解PLA共混体系、PLA填充体系和PLA共聚体系等;阐释了不同PLA体系开孔材料的制备工艺、开孔性能(泡孔形态、尺寸及其分布、开孔率等)与力学性能等;介绍了PLA开孔材料的特性及应用。

中图分类号:

魏诗艺, 唐韵韬, 柴晨泽, 张玉霞, 周洪福. 聚乳酸开孔材料研究进展[J]. 中国塑料, 2020, 34(10): 100-109.

WEI Shiyi, TANG Yuntao, CHAI Chenze, ZHANG Yuxia, ZHOU Hongfu. Research Progress in Poly(lactic acid) Open⁃Cell Materials[J]. China Plastics, 2020, 34(10): 100-109.

| 1 | 陈 振, 张增志, 丛中卉, 等. 开孔型聚合物发泡材料的研究及应用进展[J]. 材料工程, 2020, 48(03): 1⁃9. |

| CHEN Z, ZHANG Z Z, CONG Z H, et al. Research and Application Progress of Open⁃cell Polymeric Foams[J]. Journal of Materials Engineering, 2020, 48(03): 1⁃9. | |

| 2 | ZHANG C, LI J, HU Z, et al. Correlation between the Acoustic and Porous Cell Morphology of Polyurethane Foam: Effect of Interconnected Porosity[J]. Materials & Design, 2012, 41: 319⁃325. |

| 3 | MI H Y, JING X, LIU Y, et al. Highly Durable Superhydrophobic Polymer Foams Fabricated by Extrusion and Supercritical CO2 Foaming for Selective Oil Absorption[J]. ACS Applied Materials & Interfaces, 2019, 11(7): 7 479⁃7 487. |

| 4 | LOPEZ⁃PERIAGO A M, VEGA A, SUBRA P, et al. Supercritical CO2 Processing of Polymers for the Production of Materials with Applications in Tissue Engineering and Drug Delivery[J]. Journal of Materials Science, 2008, 43(6): 1 939⁃1 947. |

| 5 | MILOVANOVIC S, MARKOVIC D, MRAKOVIC A, et al. Supercritical CO2⁃assisted Production of PLA and PLGA Foams for Controlled Thymol Release[J]. Materials Science and Engineering: C, 2019, 99: 394⁃404. |

| 6 | 黄英珠. 超临界流体技术制备聚丙烯开孔发泡材料的研究[D]. 北京: 北京化工大学, 2009. |

| 7 | ENAYATI M S, FAMILI M H N, JANANI H. Production of Polystyrene Open⁃celled Microcellular Foam in Batch Process by Supercritical CO2[J]. Iran. J. Polym. Sci. Technol.(In Persian), 2010, 23: 223⁃234. |

| 8 | 曾月莲, 刘秀生, 兰家勇, 等. 聚氨酯开孔硬质泡沫降噪性能的研究[J]. 聚氨酯工业, 2008(01): 18⁃20. |

| ZENG Y L, LIU X S, LAN J Y, et al. Noise Reduction Properties of Rigid Polyurethane Open⁃Cell Foam[J]. Polyurethane Industry, 2008(01): 18⁃20. | |

| 9 | STANDAU T, ZHAO C, MURILLO CASTELLÓN S, et al. Chemical Modification and Foam Processing of Polylactide (PLA)[J]. Polymers, 2019, 11(2): 306. |

| 10 | LEE S H, KIM I Y, SONG W S. Biodegradation of Polylactic Acid (PLA) Fibers Using Different Enzymes[J]. Macromolecular Research, 2014, 22(6): 657⁃663. |

| 11 | SILVA D, KADURI M, POLEY M, et al. Biocompatibility, Biodegradation and Excretion of Polylactic Acid (PLA) in Medical Implants and Theranostic Systems[J]. Chemical Engineering Journal, 2018, 340: 9⁃14. |

| 12 | SHI H S, GAN Q, LIU X W, et al. Poly (glycerol sebacate)⁃modified Polylactic Acid Scaffolds with Improved Hydrophilicity, Mechanical Strength and Bioactivity for Bone Tissue Regeneration [J]. RSC Advances, 2015, 5(97): 79703⁃79714. |

| 13 | 朱惠光, 计 剑, 高长有, 等. 聚乳酸组织工程支架材料[J]. 功能高分子学报, 2001(04): 488⁃492. |

| ZHU H G, JI J, GAO C Y, et al. Poly (lactic acid) (PLA) as Tissue Engineering Scaffold[J]. Journal of Functional Polymers, 2001(04): 488⁃492. | |

| 14 | WANG S G, CUI W J, BEI J Z. Bulk and Surface Modifications of Polylactide[J]. Analytical and Bioanalytical Chemistry, 2005, 381(3): 547⁃556. |

| 15 | 肖 淼, 杨 其 ,蔡盛梅, 等. PCL增韧PLA共混材料的制备与性能研究[J]. 塑料工业, 2010, 38(06): 15⁃18. |

| XIAO M, YANG Q, CAI S M, et al. Preparation and Property Study of PCL Toughening PLA Materials[J]. China Plastics Industry, 2010, 38(06): 15⁃18. | |

| 16 | WANG L X, WANG D F, ZHOU Y P, et al. Fabrication of Open⁃porous PCL/PLA Tissue Engineering Scaffolds and the Relationship of Foaming Process, Morphology, and Mechanical Behavior[J]. Polymers for Advanced Technologies, 2019, 30(10): 2 539⁃2 548. |

| 17 | LV Z R, ZHAO N, WU Z M, et al. Fabrication of Novel Open⁃Cell Foams of Poly (ε⁃caprolactone)/poly (lactic acid) Blends for Tissue⁃engineering Scaffolds[J]. Industrial & Engineering Chemistry Research, 2018, 57(39): 12 951⁃12 958. |

| 18 | 张云飞, 黄安平, 张文学,等. PLA/PBAT复合材料研究进展[J]. 工程塑料应用, 2019, 47(01): 154⁃158. |

| ZHANG Y F, HUANG A P, ZHANG W X, et al. Research Progress of PLA/PBAT Composites[J]. Engineering Plastics Application, 2019, 47(01): 154⁃158. | |

| 19 | KANG Y, CHEN P, SHI X T, et al. Preparation of Open⁃porous Stereocomplex PLA/PBAT Scaffolds and Correlation Between Their Morphology, Mechanical Behavior, and Cell Compatibility[J]. RSC Advances, 2018, 8(23): 12 933⁃12 943. |

| 20 | 杨弯弯, 梁 奎, 陈绪煌, 等. 聚乳酸开孔型微孔材料的制备及开孔机理[J]. 高分子材料科学与工程, 2017, 33(11): 152⁃157. |

| YANG W W, LIANG K, CHEN X H, et al. Preparation of Polylactic Acid Opening Microporous Materials and Its Opening Mechanism[J]. Polymer Materials Science & Engineering, 2017, 33(11): 152⁃157. | |

| 21 | DENG Y, THOMAS N L. Blending Poly(butylene succinate) with Poly(lactic acid): Ductility and Phase Inversion Effects[J]. European Polymer Journal, 2015, 71: 534⁃546. |

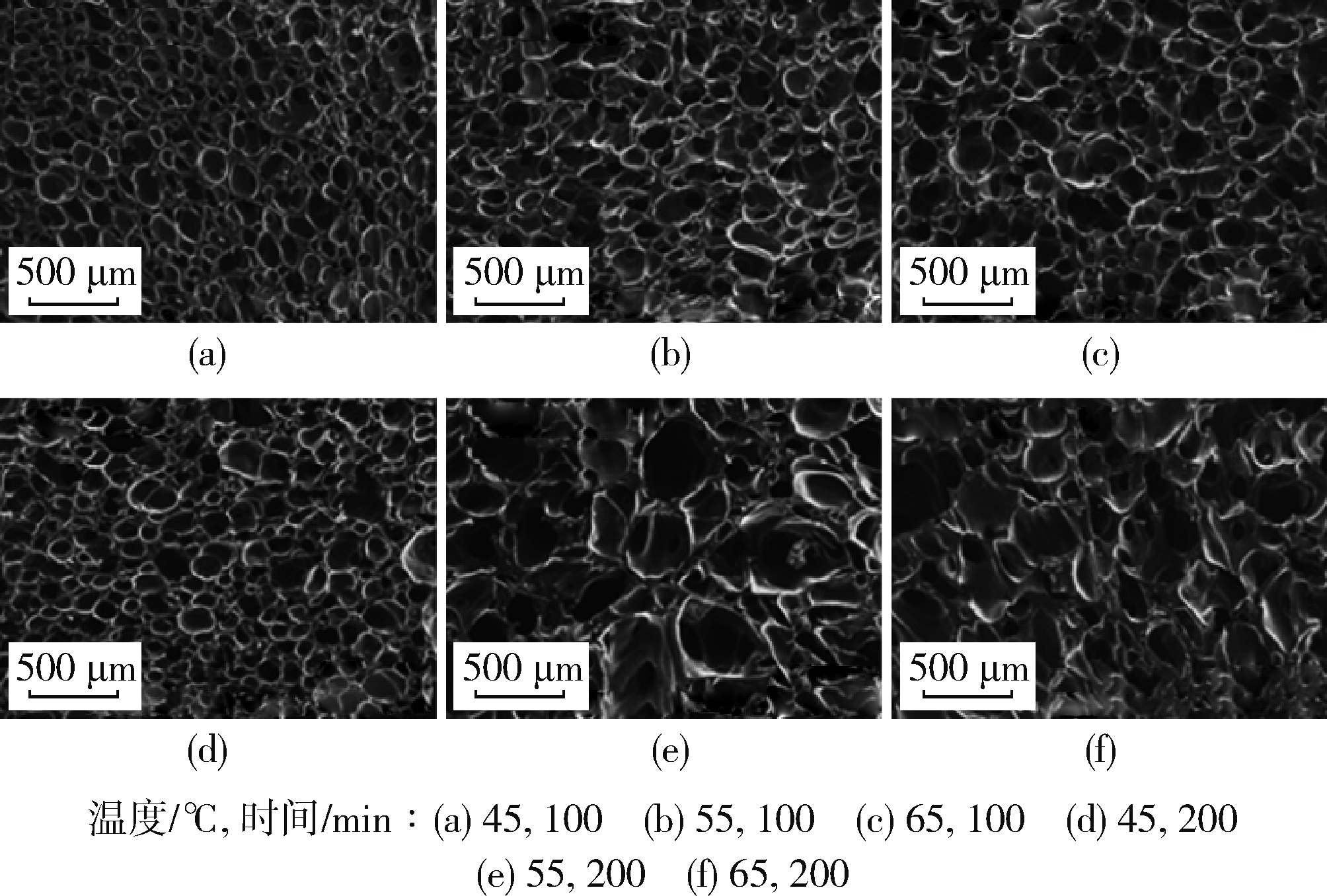

| 22 | SHI X T, WANG L, KANG Y, et al. Effect of Poly(butylenes succinate) on the Microcellular Foaming of Polylactide Using Supercritical Carbon Dioxide[J]. Journal of Polymer Research, 2018, 25(11): 229⁃240. |

| 23 | YU P, MI H Y, HUANG A, et al. Effect of Poly (butylenes succinate) on Poly (lactic acid) Foaming Behavior: Formation of Open Cell Structure[J]. Industrial & Engineering Chemistry Research, 2015, 54(23): 6 199⁃6 207. |

| 24 | 杨友斌, 吴启凡, 郑红娟. 不同处理剂对PLA/SiO2复合材料性能的影响[J]. 塑料工业, 2015, 43(11): 119⁃123. |

| YANG Y B, WU Q F, ZHEN H J. Effects of Different Modification Agents on Properties of PLA/SiO2 Composites[J]. China Plastics Industry, 2015, 43(11): 119⁃123. | |

| 25 | COLLINS N J, LEEKE G A, BRIDSON R H, et al. The Influence of Silica on Pore Diameter and Distribution in PLA Scaffolds Produced Using Supercritical CO2[J]. Journal of Materials Science: Materials in Medicine, 2008, 19(4): 1 497⁃1 502. |

| 26 | COLLINS N J, BRIDSON R H, LEEKE G A, et al. Particle Seeding Enhances Interconnectivity in Polymeric Scaffolds Foamed Using Supercritical CO2[J]. Acta Biomaterialia, 2010, 6(3): 1 055⁃1 060. |

| 27 | YIN Y Y, ZHAO L N, JIANG X, et al. Poly (lactic acid)⁃based biocomposites reinforced with modified cellulose nanocrystals[J]. Cellulose, 2017, 24(11): 4 773⁃4 784. |

| 28 | BORKOTOKY S S, DHAR P, KATIYAR V. Biodegradable Poly (lactic acid)/cellulose Nanocrystals (CNCs) Composite Microcellular Foam: Effect of Nanofillers on Foam Cellular Morphology, Thermal and Wettability Behavior[J]. International Journal of Biological Macromolecules, 2018, 106: 433⁃446. |

| 29 | LUO W H, CHENG L H, YUAN C X, et al. Preparation, Characterization and Evaluation of Cellulose Nanocrystal/poly (lactic acid) in situ Nanocomposite Scaffolds for Tissue Engineering[J]. International Journal of Biological Macromolecules, 2019, 134: 469⁃479. |

| 30 | 余旺旺, 李卫红, 张 静, 等. PLA/nano⁃SiO2/HA三元复合生物材料的力学及体外降解性能研究[J]. 塑料科技, 2019, 47(10): 83⁃87. |

| YU W W, LI W H, ZHANG J, et al. Study on Mechanical and In⁃vitro Degradation Properties of PLA/nano⁃SiO2/HA Ternary Composite Biomaterials[J]. Plastics Science and Technology, 2019, 47(10): 83⁃87. | |

| 31 | TENG X R, REN J, GU S Y. Preparation and Characterization of Porous PDLLA/HA Composite Foams by Supercritical Carbon Dioxide Technology[J]. Journal of Biomedical Materials Research Part B: Applied Biomaterials: An Official Journal of The Society for Biomaterials, The Japanese Society for Biomaterials, and The Australian Society for Biomaterials and the Korean Society for Biomaterials, 2007, 81(1): 185⁃193. |

| 32 | WANG X H, SHI S, GUO G, et al. Preparation and Characterization of a Porous Scaffold Based on Poly(D, L⁃lactide) and N⁃hydroxyapatite by Phase Separation[J]. Journal of Biomaterials Science, Polymer Edition, 2011, 22(14): 1 917⁃1 929. |

| 33 | 葛建华, 王迎军, 陈晓峰, 等. 生物活性玻璃/PLA⁃PEG⁃PLA/聚乳酸组织工程支架在SBF溶液中的降解和矿化[J]. 复合材料学报, 2013, 30(06): 96⁃100. |

| GE J H, WANG Y J, CHEN X F, et al. Degradable Performance and Bio⁃Mineralization Function of Bioglass/PLA⁃PEG⁃PLA/poly (Lactic acid) Tissue Engineering Scaffold in SBF[J]. Acta Materiae Compositae Sinica, 2013, 30(06): 96⁃100. | |

| 34 | ZHANG K, WANG Y B, HILLMYER M A, et al. Processing and Properties of Porous Poly (L⁃lactide)/bioactive Glass Composites[J]. Biomaterials, 2004, 25(13): 2 489⁃2 500. |

| 35 | 马丽娟, 邓久鹏, 尹浩月, 等. 真空冷冻干燥法制备聚乳酸/生物玻璃支架及性能研究[J]. 中国组织工程研究, 2019, 23(30): 4 793⁃4 798. |

| MA L J, DENG J P, YIN H Y, et al. Preparation of Polylactic Acid/ bioactive Glass Composite Material by Vacuum Freeze⁃drying Technique and Study on Its Performance[J]. Chinese Journal of Tissue Engineering Research, 2019, 23(30): 4 793⁃4 798. | |

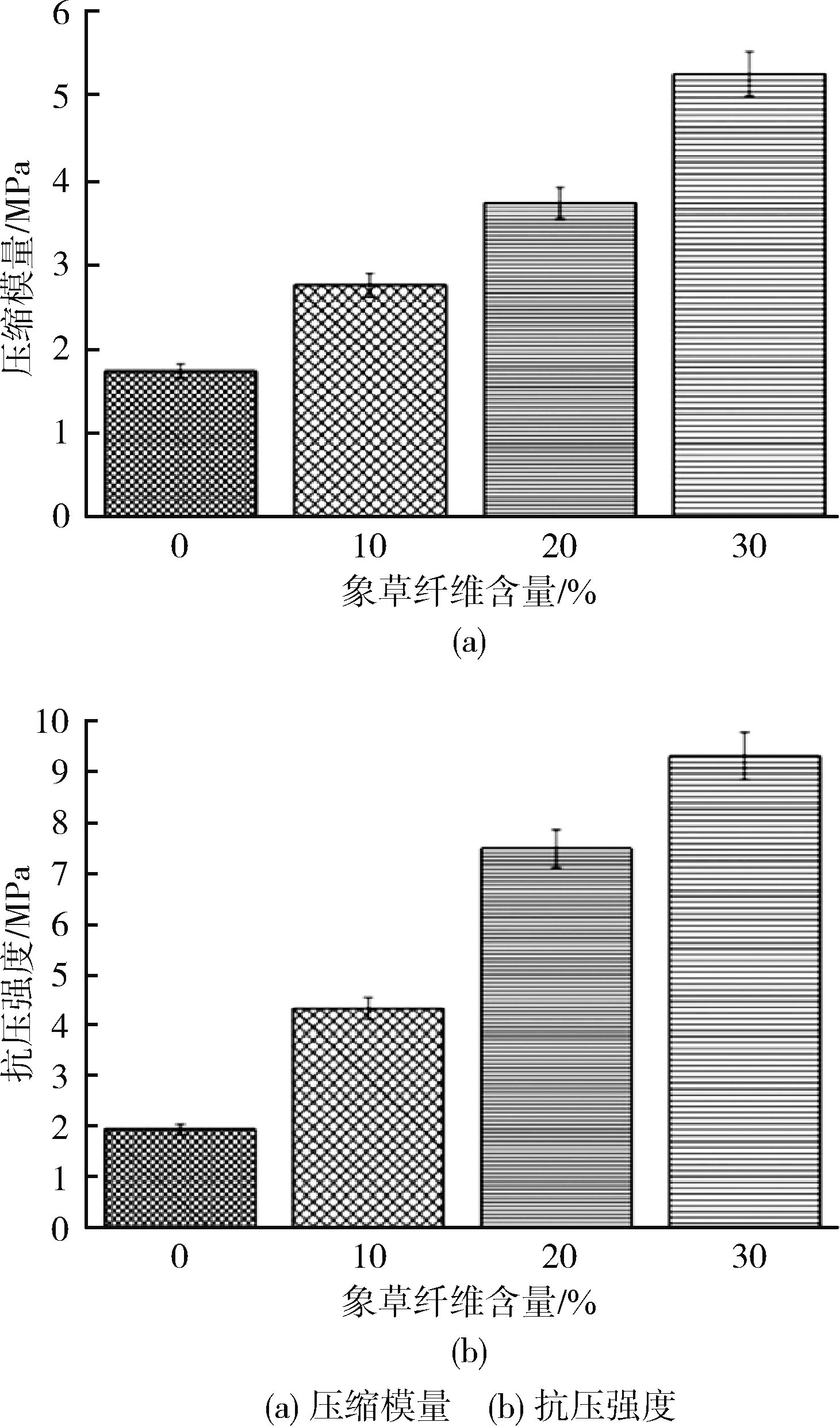

| 36 | JA M H, MAJID M S A, AFENDI M, et al. Mechanical Properties of Napier Grass Fibre/polyester Composites[J]. Composite Structures, 2016, 136: 1⁃10. |

| 37 | REVATI R, MAJID M S A, RIDZUAN M J M, et al. Mechanical, Thermal and Morphological Characterisation of 3D Porous Pennisetum Purpureum/PLA Biocomposites Scaffold[J]. Materials Science and Engineering: C, 2017, 75: 752⁃759. |

| 38 | REVATI R, MAJID M S A, RIDZUAN M J M, et al. In Vitro Degradation of a 3D Porous Pennisetum purpureum/PLA Biocomposite Scaffold[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 74: 383⁃391. |

| 39 | 徐文峰, 廖晓玲. 碳纤维/聚乳酸/壳聚糖三元多孔复合支架材料的制备及评价[J]. 材料导报, 2010, 24(24): 114⁃117. |

| XU W F, LIAO X L. Preparation and Evaluation of Porous 3D CF/PLA/CS Composites Scaffold[J]. Materials Review, 2010, 24(24): 114⁃117. | |

| 40 | 汪学军, 楼 涛, 宋国君. 聚乳酸/壳聚糖纤维复合支架的制备与性能[J]. 中国组织工程研究与临床康复, 2010, 14(42): 7 854⁃7 856. |

| WANG X J, LOU T, SONG G J. Preparation and Characterization of Poly⁃L⁃lactic Acid/chitosan Fibers Composite Scaffold[J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2010, 14(42): 7 854⁃7 856. | |

| 41 | 崔文瑾, 贝建中, 王身国. 聚丙交酯及其共聚物的研究进展[J]. 高分子通报, 2005(5): 16⁃23+30. |

| CUI W J, BEI J Z, WANG S G. Research Development of Polylactide and its Copolymers[J]. Polymer Bulletin, 2005(5): 16⁃23+30. | |

| 42 | JUNG Y, PARK M S, LEE J W, et al. Cartilage Regeneration with Highly⁃elastic three⁃dimensional Scaffolds Prepared from Biodegradable Poly(l⁃lactide⁃co⁃ɛ⁃ caprolactone)[J]. Biomaterials, 2008, 29(35): 4 630⁃4 636. |

| 43 | KIM S H, JUNG Y, KIM S H. A Biocompatible Tissue Scaffold Produced by Supercritical Fluid Processing for Cartilage Tissue Engineering[J]. Tissue Engineering Part C: Methods, 2013, 19(3): 181⁃188. |

| 44 | 迟长龙, 王延伟, 杨秀琴, 等. PLA/PEG复合材料结晶行为研究[J]. 塑料科技, 2015, 43(02): 38⁃41. |

| CHI C L, WANG Y W, YANG X Q, et al. Study on Crystallization Behavior of PLA/PEG Composite System[J]. Plastics Science and Technology, 2015, 43(02): 38⁃41. | |

| 45 | EGRI S, ECZACıOGLU N. Sequential VEGF and BMP⁃2 Releasing PLA⁃PEG⁃PLA Scaffolds for Bone Tissue Engineering: I. Design and in Vitro Tests[J]. Artificial Cells, Nanomedicine, and Biotechnology, 2017, 45(2): 321⁃329. |

| 46 | WANG N, ZANG Y J, REN G Z, et al. Fabrication and Properties of Porous Scaffolds of PLA⁃PEG Biocomposite for Bone Tissue Engineering[J]. Materials Science Forum, 2014, 789: 130⁃135. |

| 47 | 吴双全, 张佩华, 郭 正. 不同比例PGA/PLA编织线的体外降解性能[J]. 东华大学学报(自然科学版), 2009, 35(03): 274⁃278+303. |

| WU S C, ZHANG P H, GUO Z. The Properties of Braided Yarns with Different PGA/PLA Proportions in Vitro Degradation[J]. Journal of Donghua University(Natural Science), 2009, 35(03): 274⁃278+303. | |

| 48 | LEUNG L, CHAN C, BAEK S, et al. Comparison of Morphology and Mechanical Properties of PLGA Bioscaffolds[J]. Biomedical Materials, 2008, 3(2): 025006. |

| 49 | 赵 莉, 何晨光, 高永娟, 等. PLGA的不同组成对支架材料性能的影响研究[J]. 中国生物工程杂志, 2008(05): 22⁃28. |

| ZHAO L, HE C G, GAO Y J, et al. Study on Influence of Copolymer Compositions of PLGA on Properties of Scaffolds[J]. China Biotechnology, 2008(05): 22⁃28. | |

| 50 | 李妍凝, 刘智峰, 包锦标, 等. 超临界流体技术制备聚合物开孔发泡材料的研究进展[J]. 材料导报, 2015, 29(17): 15⁃21. |

| LI Y N, LIU Z F, BAO J B, et al. Review on the Progress of Open⁃cell Polymeric Foams[J]. Materials Review, 2015, 29(17): 15⁃21. | |

| 51 | GARLOTTA D. A Literature Review of Poly(lactic acid)[J]. Journal of Polymers and the Environment, 2001, 9(2): 63⁃84. |

| 52 | 罗 剑, 张兰军, 李星平. 多孔材料在公路吸声降噪上的应用与探讨[J]. 山西建筑, 2008(27): 192⁃193. |

| LUO J, ZHANG L J, LI X P. The Application and Discussion of Cellular Material in Highway Noise Reduction[J]. Shanxi Architecture, 2008(27): 192⁃193. | |

| 53 | 李海涛, 朱 锡, 石 勇, 等. 多孔性吸声材料的研究进展[J]. 材料科学与工程学报, 2004(06): 934⁃938. |

| LI H T, ZHU X, SHI Y, et al. Developments of Porous Sound⁃absorbing Materials[J]. Journal of Materials Science and Engineering, 2004(06): 934⁃938. | |

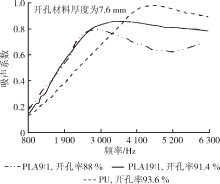

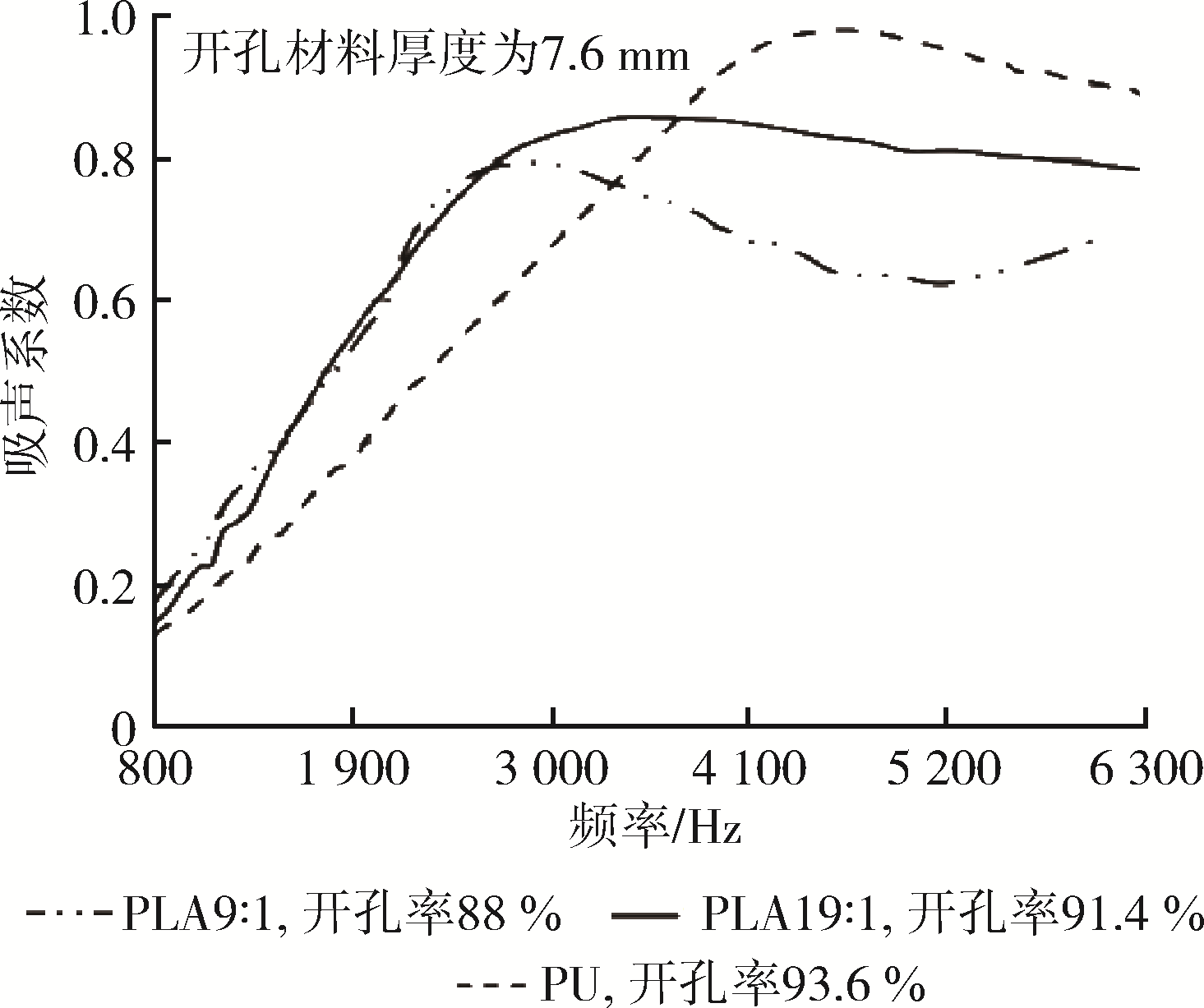

| 54 | GHAFFARI MOSANENZADEH S, NAGUIB H E, PARK C B, et al. Effect of Biopolymer Blends on Physical and Acoustical Properties of Biocomposite Foams[J]. Journal of Polymer Science Part B: Polymer Physics, 2014, 52(15): 1 002⁃1 013. |

| 55 | MOSANENZADEH S G, NAGUIB H E, PARK C B, et al. Development, Characterization, and Modeling of Environmentally Friendly Open⁃cell Acoustic Foams[J]. Polymer Engineering & Science, 2013, 53(9): 1 979⁃1 989. |

| 56 | XUE Z X, SUN Z X, CAO Y Z, et al. Superoleophilic and Superhydrophobic Biodegradable Material with Porous Structures for Oil Absorption and Oil–water Separation[J]. Rsc Advances, 2013, 3(45): 23 432⁃23 437. |

| 57 | ZHANG W, LIU M, LIU Y Y, et al. 3D Porous Poly (L⁃lactic acid) Foams Composed of Nanofibers, Nanofibrous Microsheaves and Microspheres and Their Application in Oil–water Separation[J]. Journal of Materials Chemistry A, 2015, 3(26): 14 054⁃14 062. |

| 58 | Li B, Ma X W, Zhao G Q, et al. Green Fabrication Method of Layered and Open⁃cell Polylactide Foams for Oil⁃sorption via Pre⁃Crystallization and Supercritical CO2⁃induced melting[J]. The Journal of Supercritical Fluids, 2020, 162. |

| 59 | YIN G Z, ZHAO D L, ZHANG L W, et al. Highly Porous 3D PLLA Materials Composed of Nanosheets, Fibrous Nanosheets, or Nanofibrous Networks: Preparation and the Potential Application in Oil–water Separation[J]. Chemical Engineering Journal, 2016, 302: 1⁃11. |

| [1] | 冯凯, 李永青, 马秀清, 韩颖. 聚甲醛增韧改性的研究进展及应用[J]. 中国塑料, 2022, 36(7): 157-164. |

| [2] | 沈雪梅, 朱小龙, 胡燕超, 宋任远, 张现峰, 李席. 静电喷雾法制备聚乳酸/布洛芬微球及其性能研究[J]. 中国塑料, 2022, 36(7): 61-67. |

| [3] | 周舒毅, 朱敏, 刘忆颖, 曹舒惠, 蔡启轩, 聂慧, 张玉霞, 周洪福. 高分子止血材料研究进展[J]. 中国塑料, 2022, 36(7): 74-84. |

| [4] | 陈轲, 刘鸣飞, 赵彪, 潘凯. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154. |

| [5] | 邵琳颖, 郗悦玮, 翁云宣. 可降解聚乳酸复合材料研究进展[J]. 中国塑料, 2022, 36(6): 155-164. |

| [6] | 邓天翔, 许利娜, 李守海, 张燕, 姚娜, 贾普友, 丁海阳, 李梅. PVC接枝改性及交联改性方法研究进展[J]. 中国塑料, 2022, 36(5): 140-148. |

| [7] | 王镕琛, 张恒, 孙焕惟, 段书霞, 秦子轩, 李晗, 朱斐超, 张一风. 医疗卫生用聚乳酸非织造材料的制备及其亲水改性研究进展[J]. 中国塑料, 2022, 36(5): 158-166. |

| [8] | 赵新新, 金晓冬, 施妍, 孙诗兵, 吕锋, 田英良, 赵志永. 基于紫外⁃臭氧辐照的挤塑聚苯乙烯表面改性研究[J]. 中国塑料, 2022, 36(5): 8-13. |

| [9] | 李梦琪, 陈雅君. 纳米材料阻燃聚乳酸的研究进展[J]. 中国塑料, 2022, 36(4): 102-114. |

| [10] | 陈文静, 杨小龙, 韩顺涛, 韩颖, 马秀清. 聚丙烯腈材料改性方法及研究进展[J]. 中国塑料, 2022, 36(4): 158-165. |

| [11] | 董露茜, 徐芳, 翁云宣. 聚乙醇酸改性及其应用研究进展[J]. 中国塑料, 2022, 36(4): 166-174. |

| [12] | 李素圆, 刘会鹏, 龚舜, 黄国桃, 李玉才, 吴鑫, 邓建平, 潘凯. 热塑性聚酰胺弹性体改性EVA复合发泡材料的制备及性能表征[J]. 中国塑料, 2022, 36(4): 6-14. |

| [13] | 马嘉森, 薛永兵, 郭旗, 刘振民. 废旧塑料改性剂改性沥青的研究进展[J]. 中国塑料, 2022, 36(2): 131-138. |

| [14] | 刘延宽, 顾子琛, 王志平. 连续纤维增强热塑性预浸料制备工艺与发展趋势[J]. 中国塑料, 2022, 36(2): 172-181. |

| [15] | 仇洪波. 基于仿生学的木材超疏水表面改性研究进展[J]. 中国塑料, 2022, 36(2): 182-196. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2