京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (9): 38-45.DOI: 10.19491/j.issn.1001-9278.2022.09.006

收稿日期:2022-05-18

出版日期:2022-09-26

发布日期:2022-09-26

作者简介:杨金(1982—),男,博士,高级工程师,从事聚合物复合材料的创新设计、成型和应用领域研究,470325362@qq.com

YANG Jin1( ), CHEN Pengran2, GAO Peixin2

), CHEN Pengran2, GAO Peixin2

Received:2022-05-18

Online:2022-09-26

Published:2022-09-26

摘要:

以对苯乙基桥链9,10⁃二氢⁃9⁃氧杂⁃10⁃磷杂菲⁃10⁃氧化物(DIDOPO)、聚甲基倍半硅氧烷(POSS)、膨胀石墨 (EG)为复配阻燃剂对环氧树脂(EP)泡沫进行阻燃改性,研究了复配阻燃剂对EP泡沫材料的阻燃效果和阻燃机理。结果表明,当DIDOPO/POSS=3∶1(质量比,下同)、DIDOPO/EG=1∶3时,复配阻燃体系的阻燃效果最佳;添加20 %(质量分数,下同) DIDOPO/POSS复配阻燃剂的加入可以使EP泡沫的UL 94测试达到V⁃0级; 添加20 %的 DIDOPO/EG复配体系可以使EP泡沫的极限氧指数(LOI)提高至30.8 %,UL 94测试达到V⁃0级;阻燃体系具有一定的抑烟效果。

中图分类号:

杨金, 陈鹏然, 高培鑫. DIDOPO与POSS/EG协同阻燃环氧树脂泡沫及机理研究[J]. 中国塑料, 2022, 36(9): 38-45.

YANG Jin, CHEN Pengran, GAO Peixin. Preparation and flame-retardant mechanism of epoxy foams synergistically modified with DIDOPO and POSS/EG[J]. China Plastics, 2022, 36(9): 38-45.

| 样品名称 | TTI/s | Td/s | PHRR/kW·m-2 | THR·TML/MJ·m-2·g-1 | CY/% | LOI/% |

|---|---|---|---|---|---|---|

| EP | 60 | 397 | 991.50 | 3.04 | 2.3 | 21.0 |

| EP 泡沫 | 13 | 492 | 444.36 | 2.93 | 3.4 | 18.4 |

| 样品名称 | TTI/s | Td/s | PHRR/kW·m-2 | THR·TML/MJ·m-2·g-1 | CY/% | LOI/% |

|---|---|---|---|---|---|---|

| EP | 60 | 397 | 991.50 | 3.04 | 2.3 | 21.0 |

| EP 泡沫 | 13 | 492 | 444.36 | 2.93 | 3.4 | 18.4 |

| 样品名称 | LOI/% | UL 94 | |

|---|---|---|---|

| t1/t2a | 等级 | ||

| EP/DIDOPO10b (未发泡) | 26.0 | 6.21/1.20 | V⁃0 |

| EP/DIDOPO5 | 20.0 | —c | NRd |

| EP/DIDOPO10 | 20.6 | — | NR |

| EP/DIDOPO15 | 22.0 | 15.33/- | NR |

| EP/DIDOPO20 | 22.6 | 8.31/17.49 | V⁃1 |

| EP/DIDOPO25 | 23.7 | 4.36/12.28 | V⁃1 |

| 样品名称 | LOI/% | UL 94 | |

|---|---|---|---|

| t1/t2a | 等级 | ||

| EP/DIDOPO10b (未发泡) | 26.0 | 6.21/1.20 | V⁃0 |

| EP/DIDOPO5 | 20.0 | —c | NRd |

| EP/DIDOPO10 | 20.6 | — | NR |

| EP/DIDOPO15 | 22.0 | 15.33/- | NR |

| EP/DIDOPO20 | 22.6 | 8.31/17.49 | V⁃1 |

| EP/DIDOPO25 | 23.7 | 4.36/12.28 | V⁃1 |

| 样品名称 | LOI/% | UL 94 | |

|---|---|---|---|

| t1/t2 | 等级 | ||

| EP/DIDOPO16/POSS4 | 22.6 | 11.15/2.37 | V⁃1 |

| EP/DIDOPO15/POSS5 | 22.8 | 7.15/1.37 | V⁃0 |

| EP/DIDOPO10/POSS10 | 22.6 | 12.78/7.84 | V⁃1 |

| EP/DIDOPO5/POSS15 | 22.8 | - | NR |

| EP/POSS20 | 20.4 | - | NR |

| EP/DIDOPO11.25/POSS3.75 | 21.8 | 17.35/8.76 | V⁃1 |

| EP/DIDOPO18.75/POSS6.25 | 25.0 | 2.51/0 | V⁃0 |

| 样品名称 | LOI/% | UL 94 | |

|---|---|---|---|

| t1/t2 | 等级 | ||

| EP/DIDOPO16/POSS4 | 22.6 | 11.15/2.37 | V⁃1 |

| EP/DIDOPO15/POSS5 | 22.8 | 7.15/1.37 | V⁃0 |

| EP/DIDOPO10/POSS10 | 22.6 | 12.78/7.84 | V⁃1 |

| EP/DIDOPO5/POSS15 | 22.8 | - | NR |

| EP/POSS20 | 20.4 | - | NR |

| EP/DIDOPO11.25/POSS3.75 | 21.8 | 17.35/8.76 | V⁃1 |

| EP/DIDOPO18.75/POSS6.25 | 25.0 | 2.51/0 | V⁃0 |

| 样品名称 | LOI/% | UL 94 | |

|---|---|---|---|

| t1/t2 | 等级 | ||

| EP/DIDOPO15/EG5 | 24.8 | 8.62/NR | NR |

| EP/DIDOPO10/EG10 | 28.8 | 1.61/2.10 | V⁃0 |

| EP/DIDOPO5/EG15 | 30.8 | 1.29/6.65 | V⁃0 |

| EP/DIDOPO6.25/EG18.75 | 28.4 | 5.67/- | NR |

| EP/DIDOPO3.75/EG11.25 | 27.0 | 4.16/18.71 | V⁃1 |

| EP/EG20 | 27.2 | - | NR |

| 样品名称 | LOI/% | UL 94 | |

|---|---|---|---|

| t1/t2 | 等级 | ||

| EP/DIDOPO15/EG5 | 24.8 | 8.62/NR | NR |

| EP/DIDOPO10/EG10 | 28.8 | 1.61/2.10 | V⁃0 |

| EP/DIDOPO5/EG15 | 30.8 | 1.29/6.65 | V⁃0 |

| EP/DIDOPO6.25/EG18.75 | 28.4 | 5.67/- | NR |

| EP/DIDOPO3.75/EG11.25 | 27.0 | 4.16/18.71 | V⁃1 |

| EP/EG20 | 27.2 | - | NR |

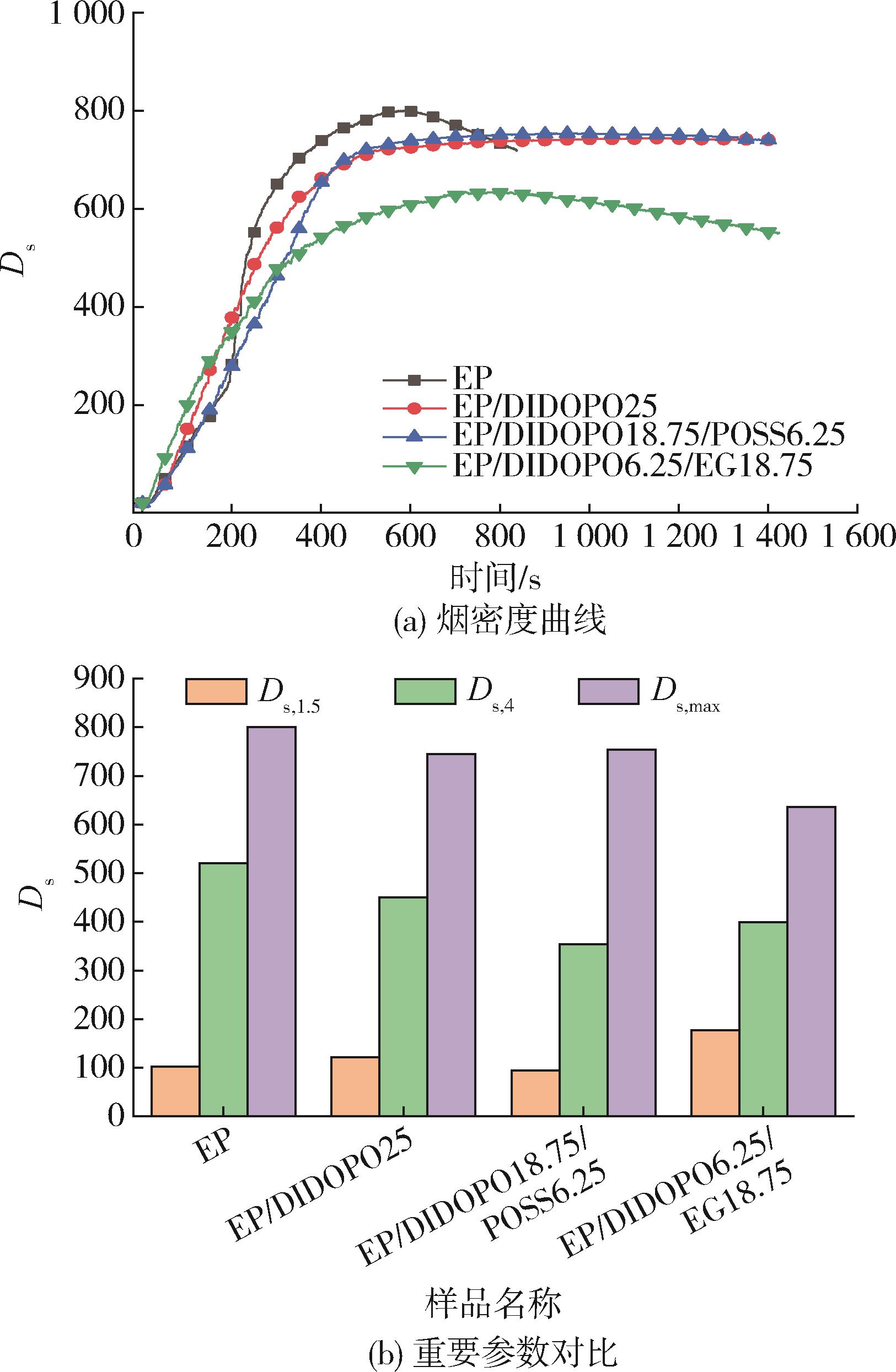

| 样品名称 | TTI/s | Td/s | PHRR/kW·m-2 | THR/MJ·m-2 | THR·TML/MJ·m-2·g-1 | TSR/m2·m2 | CY/% |

|---|---|---|---|---|---|---|---|

| EP | 13 | 492 | 444.36 | 149.85 | 2.93 | 4282 | 3.4 |

| EP/DIDOPO25 | 40 | 603 | 285.58 | 113.86 | 1.75 | 10834 | 8.2 |

| EP/DIDOPO18.75/POSS6.25 | 18 | 633 | 241.09 | 112.34 | 1.86 | 8685 | 16.1 |

| EP/DIDOPO6.25/EG18.75 | 11 | 884 | 66.48 | 81.80 | 2.50 | 393 | 56.5 |

| EP/DIDOPO5/EG15 | 15 | 1823 | 181.05 | 99.05 | 3.18 | 1013 | 53.3 |

| 样品名称 | TTI/s | Td/s | PHRR/kW·m-2 | THR/MJ·m-2 | THR·TML/MJ·m-2·g-1 | TSR/m2·m2 | CY/% |

|---|---|---|---|---|---|---|---|

| EP | 13 | 492 | 444.36 | 149.85 | 2.93 | 4282 | 3.4 |

| EP/DIDOPO25 | 40 | 603 | 285.58 | 113.86 | 1.75 | 10834 | 8.2 |

| EP/DIDOPO18.75/POSS6.25 | 18 | 633 | 241.09 | 112.34 | 1.86 | 8685 | 16.1 |

| EP/DIDOPO6.25/EG18.75 | 11 | 884 | 66.48 | 81.80 | 2.50 | 393 | 56.5 |

| EP/DIDOPO5/EG15 | 15 | 1823 | 181.05 | 99.05 | 3.18 | 1013 | 53.3 |

| 1 | 马玉峰. 轻质阻燃酚醛泡沫材料的制备与构效关系研究[D].北京:中国林业科学研究院, 2013. |

| 2 | 王国振. 酚醛树脂泡沫的增韧及阻燃改性研究[D].昌吉:昌吉学院, 2016. |

| 3 | ZHU Z M, XU Y J, LIAO W, et al. Highly flame retardant expanded polystyrene foams from phosphorus⁃nitrogen⁃silicon synergistic adhesives[J]. Industrial & Engineering Chemistry Research, 2017, 56(16): 4 649⁃4 658. |

| 4 | 纪文斐. 无卤阻燃聚苯乙烯泡沫的制备和阻燃机理研究[D]. 北京:北京化工大学, 2019. |

| 5 | WANG C, WU Y C, LI Y C, et al. Flame⁃retardant rigid polyurethane foam with a phosphorus⁃nitrogen single intumescent flame retardant[J]. Polymers for Advanced Technologies, 2018, 29(1): 668⁃676. |

| 6 | 薛竹林, 王亚凤, 闫莉,等. 反应型含磷多元醇/APP复配阻燃聚氨酯泡沫的制备及性能[J].塑料科技, 2019, 47(5): 31⁃36. |

| XUE Z L, WANG Y F, YAN L, et al. Preparation and properties of reactive phosphorus containing polyol/app flame retardant polyurethane foam[J]. Plastics Science and Technology, 2019, 47(5): 31⁃36. | |

| 7 | 姜存华. 阻燃高分子材料的研究进展及其在工程领域的应用[J].化工设计通讯,2020, 46(8): 101,109. |

| JIANG C H. Research progress of flame retardant polymer materials and its application in engineering[J]. Chemical Engineering Design Communications,2020, 46(8): 101,109. | |

| 8 | LIU Q Y, WANG D H, LI Z K, et al. Recent developments in the flame⁃retardant system of epoxy resin[J]. Materials, 2020, 13(9): 2145. |

| 9 | 周亚东. 高分子材料阻燃改性研究进展[J].广州化工,2013, 41(3): 18⁃20. |

| ZHOU Y D. The research progress in flame retardant of polymer materials[J]. Guangzhou Chemical Industry,2013, 41(3): 18⁃20. | |

| 10 | DUQUESNE S, LE BRAS M, BOURBIGOT S, et al. Expandable graphite: a fire retardant additive for polyurethane coatings[J]. Fire and Materials, 2003, 27(3): 103⁃117. |

| 11 | LAACHACHI A, BURGER N, APAYDIN K, et al. Is expanded graphite acting as flame retardant in epoxy resin?[J]. Polymer Degradation and Stability, 2015, 117: 22⁃29. |

| 12 | WANG Z Y, HAN E, KE W. Influence of expandable graphite on fire resistance and water resistance of flame⁃retardant coatings[J]. Corrosion Science, 2007, 49(5): 2 237⁃2 253. |

| 13 | HUO S Q, SONG P A, YU B, et al. Phosphorus⁃containing flame retardant epoxy thermosets: recent advances and future perspectives[J]. Progress in Polymer Science, 2021, 114:101366. |

| 14 | YAN W, YU J, ZHANG M Q, et al. Flame⁃retardant effect of a phenethyl⁃bridged DOPO derivative and layered double hydroxides for epoxy resin[J]. Rsc Advances, 2017, 7(73): 46 236⁃46 245. |

| 15 | YAN W, YU J, ZHANG M Q, et al. Enhanced flame retardancy of epoxy resin containing a phenethyl⁃bridged DOPO derivative/montmorillonite compound[J]. Journal of Fire Sciences, 2018, 36(1): 47⁃62. |

| 16 | WANG X, HU Y A, SONG L, et al. Thermal degradation behaviors of epoxy resin/POSS hybrids and phosphorus⁃silicon synergism of flame retardancy[J]. Journal of Polymer Science Part B⁃Polymer Physics, 2010, 48(6): 693⁃705. |

| 17 | 曲立杰. 磷/氮/硅/石墨烯协效阻燃EP的性能研究[D]. 长春:吉林大学, 2020. |

| 18 | YAN L, XU Z S, DENG N, et al. Synergistic effects of mono⁃component intumescent flame retardant grafted with carbon black on flame retardancy and smoke suppression properties of epoxy resins[J]. Journal of Thermal Analysis and Calorimetry, 2019, 138(2): 915⁃927. |

| 19 | HUANG J L, GUO W W, WANG X, et al. Combination of cardanol⁃derived flame retardant with SiO2@MOF particles for simultaneously enhancing the toughness, anti⁃flammability and smoke suppression of epoxy thermosets[J]. Composites Communications, 2021, 27:doi.org/10.1016/j.coco.2021.100904. |

| 20 | XIANG Y S, WANG L J, YANG Z, et al. Effect of aluminum phosphinate on the flame⁃retardant properties of epoxy syntactic foams[J]. Journal of Thermal Analysis and Calorimetry, 2019, 137(5): 1 645⁃1 656. |

| 21 | 赖学军. 耐水高效膨胀型阻燃剂的制备及其阻燃聚丙烯的研究[D]. 广州:华南理工大学, 2012. |

| [1] | 宋德建, 于鹏, 彭进松, 许苗军. 阻燃EVA热熔胶的制备及其在线缆修复中的应用研究[J]. 中国塑料, 2022, 36(9): 53-56. |

| [2] | 孟鑫, 王小龙, 公维光, 金谊. “三源一体”壳核型阻燃剂的制备及其在聚乳酸中的应用[J]. 中国塑料, 2022, 36(9): 96-104. |

| [3] | 李娟, 李莹, 郭晓林, 张晨. 中国挤出聚苯乙烯(XPS)泡沫行业CO2混合发泡技术安全生产规范[J]. 中国塑料, 2022, 36(9): 160-166. |

| [4] | 李亚飞, 孙小杰, 任月庆, 张寅灵. 阻燃抗静电聚烯烃板材的制备与性能研究[J]. 中国塑料, 2022, 36(8): 23-27. |

| [5] | 杨智, 奚望, 钱立军, 胡立双. 四元复合体系在硬质聚氨酯泡沫材料中的逐级释放阻燃行为研究[J]. 中国塑料, 2022, 36(8): 28-35. |

| [6] | 陈佰全, 郑友明, 田际波, 张磊, 王金松, 林夏洁, 段亚鹏. 高含量玻璃纤维增强阻燃聚酰胺材料的制备与性能[J]. 中国塑料, 2022, 36(8): 42-48. |

| [7] | 郭孝磊, 罗静云, 丁欣, 王雨辰, 聂铭罕, 宋佳洁, 张艳娥, 胡晶. PHBV扩链改性及其发泡行为研究[J]. 中国塑料, 2022, 36(8): 73-79. |

| [8] | 吴唯, 胡焕波, 沈辉, 赵天瑜. 4A沸石与钙镁铝水滑石对膨胀阻燃聚丙烯的双重协效阻燃作用与机理[J]. 中国塑料, 2022, 36(7): 1-7. |

| [9] | 魏思淼, 邵路山, 许准, 刘艳婷, 赵思衡, 许博. 次磷酸盐⁃环四硅氧烷双基化合物复配二乙基次磷酸铝对PA6的阻燃性能研究[J]. 中国塑料, 2022, 36(7): 129-135. |

| [10] | 谭立钦, 刘伟区, 梁利岩, 王硕, 冯志强, 林家明. 含巯基聚硅氧烷改性环氧树脂的制备及性能[J]. 中国塑料, 2022, 36(7): 21-29. |

| [11] | 徐杰, 钟进福, 童晓茜, 李广富, 付栋梁, 李城城. 端羧基修饰单宁酸/没食子酸环氧树脂复合材料的制备与性能研究[J]. 中国塑料, 2022, 36(7): 44-50. |

| [12] | 李金凤, 梁卓恩, 彭新龙. 膨胀型阻燃剂/二乙基次磷酸铝阻燃改性不饱和树脂基复合材料[J]. 中国塑料, 2022, 36(6): 116-123. |

| [13] | 陈轲, 刘鸣飞, 赵彪, 潘凯. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154. |

| [14] | 王帅, 张玉迪, 杨富凯, 徐新宇. 聚酰亚胺/多壁碳纳米管泡沫材料的制备及性能研究[J]. 中国塑料, 2022, 36(6): 39-45. |

| [15] | 孙旗, 高兴, 崔雪梅, 连慧琴, 崔秀国, 汪晓东. 黑磷烯纳米阻燃剂研究进展[J]. 中国塑料, 2022, 36(5): 133-139. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2