京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (2): 87-94.DOI: 10.19491/j.issn.1001-9278.2024.02.014

收稿日期:2023-08-14

出版日期:2024-02-26

发布日期:2024-02-03

通讯作者:

高海南(1987—),女,副教授,主要从事生物基水凝胶及气凝胶材料的制备和性能研究,gaohn@btbu.edu.cn

TONG Yaxuan1, GAO Hainan1( ), CHEN Liping2, WENG Yunxuan1,3(

), CHEN Liping2, WENG Yunxuan1,3( )

)

Received:2023-08-14

Online:2024-02-26

Published:2024-02-03

Contact:

GAO Hainan, WENG Yunxuan

E-mail:gaohn@btbu.edu.cn;wyxuan@th.btbu.edu.cn

摘要:

主要综述了生物基气凝胶在阻燃和疏水性能及其他功能化改性方面的主要方法;并对改性的生物基气凝胶在防火阻燃、环境修复、储能、生物医药等领域的相关应用进展进行综述;最后,对生物基气凝胶的发展过程中仍存在的科学及技术问题进行分析,并对功能化的生物基气凝胶发展前景进行展望。

中图分类号:

佟亚轩, 高海南, 陈礼平, 翁云宣. 生物基气凝胶的改性及功能化研究进展[J]. 中国塑料, 2024, 38(2): 87-94.

TONG Yaxuan, GAO Hainan, CHEN Liping, WENG Yunxuan. Research progress in modification and functionalization of bio⁃based aerogels[J]. China Plastics, 2024, 38(2): 87-94.

| 样品 | 热导率/W·mK-1 | 使用寿命/年 | 性能 |

|---|---|---|---|

| 聚苯乙烯泡沫 | 0.045 | 30 | 强度差、易老化 |

| 聚氨酯泡沫 | 0.024 | 15 | 稳定性差 |

| 纳米纤维素气凝胶 | 0.020 | 20 | 性能稳定 |

| 样品 | 热导率/W·mK-1 | 使用寿命/年 | 性能 |

|---|---|---|---|

| 聚苯乙烯泡沫 | 0.045 | 30 | 强度差、易老化 |

| 聚氨酯泡沫 | 0.024 | 15 | 稳定性差 |

| 纳米纤维素气凝胶 | 0.020 | 20 | 性能稳定 |

| 1 | Shi Jianjun, Lu Lingbin, Guo Wantao, et al. Heat insulation performance, mechanics and hydrophobic modification of cellulose⁃SiO2 composite aerogels [J]. Carbohydrate Polymers, 2013, 98(1): 282⁃289. |

| 2 | Barrios Elizabeth, Fox David, Yuen Yee Li Sip, et al. Nanomaterials in advanced, high⁃performance aerogel composites: a review [J]. Polymers (Basel), 2019, 11(4): 726. |

| 3 | Stergar Janja, Maver Uroš. Review of aerogel⁃based materials in biomedical applications [J]. Journal of Sol⁃Gel Science and Technology, 2016, 77(3): 738⁃752. |

| 4 | Xing Shicui, Ji Qiyan, Jiao Xiuling, et al. A two⁃step route to SiO2 nanofiber⁃reinforced aerogel composites with lightweight and high temperature resistance for thermal insulation [J]. ACS Applied Nano Materials, 2023, 6(11): 9 939⁃9 948. |

| 5 | Zhu Jundong, Jiang Hu, Jiang Chongwen, et al. Ultralight, hydrophobic, monolithic konjac glucomannan⁃silica composite aerogel with thermal insulation and mechanical properties [J]. Carbohydrate Polymers, 2019, 207: 246⁃255. |

| 6 | Dayarian Shima, Liu Yang,Hojat Majedi Far. Development of polyimide aerogel stock shapes through polyimide aerogel particles [J]. Journal of Porous Materials, 2023,30(6): 2 101⁃2 112. |

| 7 | Zhao Haibo, Chen Mingjun, Chen Hongbing. Thermally insulating and flame⁃retardant polyaniline/pectin aerogels [J]. ACS Sustainable Chemistry & Engineering, 2017, 5(8): 7 012⁃7 019. |

| 8 | Wang Yudong, Ge⁃Zhang Shangjie, Mu Pingxuan, et al. Advances in sol⁃gel⁃based superhydrophobic coatings for wood: A review [J]. International Journal of Molecular Sciences, 2023, 24(11): 9675. |

| 9 | Takeshita Satoru, Konishi Arata, Takebayashi Yoshihiro, et al. Aldehyde approach to hydrophobic modification of chitosan aerogels [J]. Biomacromolecules, 2017, 18(7): 2 172⁃2 178. |

| 10 | Chen Zicheng, Fan Guangyuan, He Xiangyang, et al. Diatomite modified with an alkyl ketene dimer for hydrophobicity of cellulosic paper [J]. ACS Omega, 2022, 7(23): 20 129⁃20 136. |

| 11 | Wei Li, Li Zerong, Wei Wang, et al. Green approach to facilely design hydrophobic aerogel directly from bagasse [J]. Industrial Crops & Products, 2021, 172: 113957. |

| 12 | Zhang Junyan, Cheng Yanhua, Xu Chengjian, et al. Hierarchical interface engineering for advanced nanocellulosic hybrid aerogels with high compressibility and multifunctionality [J]. Advanced Functional Materials, 2021, 31(19): 2009349. |

| 13 | Schroeter Baldur, Jung Isabella, Bauer Katharina, et al. Hydrophobic modification of biopolymer aerogels by cold plasma coating [J]. Polymers, 2021, 13(17): 3000. |

| 14 | Chandy Thomas, Das Gladwin S, Wilson Robert F, et al. Use of plasma glow for surface⁃engineering biomolecules to enhance bloodcompatibility of dacron and ptfe vascular prosthesis [J]. Biomaterials, 2000, 21(7): 699⁃712. |

| 15 | He Bianyang, Zhang Yaoyao, Li Bojie, et al. Preparation and hydrophobic modification of carboxymethyl chitosan aerogels and their application as an oil adsorption material [J]. Journal of Environmental Chemical Engineering, 2021, 9(5): 106333. |

| 16 | Jia Liu, Yu Juan, Xu Chaoqun, et al. One⁃pot and one⁃step preparation of “living” cellulose nanofiber hydrogel with active double⁃bond via chemical vapor deposition [J]. International Journal of Biological Macromolecules, 2023, 245: 125415. |

| 17 | Vernardou Dimitra. Special issue: Advances in chemical vapor deposition [J]. Materials, 2020, 13(18): 4167. |

| 18 | Iqbal Muzammil, Duy Khoe Dinh, Abbas Qasim, et al. Controlled surface wettability by plasma polymer surface modification [J]. Surfaces, 2019, 2(2): 349⁃371. |

| 19 | Fan Bingjie, Wu Leilei, Ming Aoxue, et al. Highly compressible and hydrophobic nanofibrillated cellulose aerogels for cyclic oil/water separation[J]. International Journal of Biological Macromolecules, 2023, 242: 125066. |

| 20 | Zhang Pengchao, Zhang Feilong, Zhao Chuangqi, et al. Superspreading on immersed gel surfaces for the confined synthesis of thin polymer films [J]. Angewandte Chemie, 2016, 128(11): 3 679⁃3 683. |

| 21 | Chen Caihong, Chao Li, Yu Deyou, et al. A facile method to prepare superhydrophobic nanocellulose⁃based aerogel with high thermal insulation performance via a two⁃step impregnation process [J]. Cellulose, 2021, 29(1): 245⁃257. |

| 22 | Tong Jutao, Gao Hainan, Weng Yunxuan, et al. Anisotropic aerogels with excellent mechanical resilience and thermal insulation from pleurotus eryngii fungus [J]. Macromolecular Materials and Engineering, 2022, 308(4): 2200538. |

| 23 | Quoc Ba Thai, Toh Ee Siang, Khac Le Duyen, et al. Advanced fabrication and multi⁃properties of rubber aerogels from car tire waste [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 577: 702⁃708. |

| 24 | Cen Qiulan, Chen Shilin, Yang Dongjie, et al. Full bio⁃based aerogel incorporating lignin for excellent flame retardancy, mechanical resistance, and thermal insulation [J]. ACS Sustainable Chemistry & Engineering, 2023, 11(11): 4 473⁃4 484. |

| 25 | Zhu Zhaoqi, Ye Niu, Wang Shuo, et al. Magnesium hydroxide coated hollow glass microspheres/chitosan composite aerogels with excellent thermal insulation and flame retardancy [J]. J Colloid Interface Sci, 2022, 612: 35⁃42. |

| 26 | Yan Sun, Chu Youlu, Chao Deng, et al. High⁃strength and superamphiphobic chitosan⁃based aerogels for thermal insulation and flame retardant applications [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 651: 129663. |

| 27 | An Zhimin, Hou Xianbo, Peng Zhou, et al. A novel flexible, layered, recoverable SiO2 fiber skeleton and aerogel composites material prepared by papermaking process [J]. Ceramics International, 2021, 47(9): 12 963⁃12 969. |

| 28 | Yue Xiaopeng, Zhang Siqian, He Jiachen, et al. Fabrication of flame retarded cellulose aerogel with hydrophobicity via MF/MTMS double cross⁃linking [J]. Journal of Natural Fibers, 2022, 20(1): 2133053. |

| 29 | He Hualing, Wang Yushu, Yu Zhicai, et al. Ecofriendly flame⁃retardant composite aerogel derived from polysaccharide: Preparation, flammability, thermal kinetics, and mechanism[J]. Carbohydrate Polymers, 2021, 269: 118291. |

| 30 | Cui Hongli, Wu Ningjing, Ma Xiaobing, et al. Superior intrinsic flame⁃retardant phosphorylated chitosan aerogel as fully sustainable thermal insulation bio⁃based material [J]. Polymer Degradation and Stability, 2023, 207: 110213. |

| 31 | Teboho Clement Mokhena, Emmanuel Rotimi Sadiku, Suprakas Sinha Ray, et al. Flame retardancy efficacy of phytic acid: An overview [J]. Journal of Applied Polymer Science, 2022, 139(27): e52495. |

| 32 | Wang Yu⁃Tao, Zhao Hai⁃Bo, Guo Mo⁃Lin, et al. Rigid and fire⁃resistant all⁃biomass aerogels [J]. ACS Sustainable Chemistry & Engineering, 2022, 10(37): 12 117⁃12 126. |

| 33 | Han Wang, Min Cao, Zhao Hai⁃Bo, et al. Double⁃cross⁃linked aerogels towards ultrahigh mechanical properties and thermal insulation at extreme environment [J]. Chemical Engineering Journal, 2020, 399: 125698. |

| 34 | Deng Shi⁃Bi, Wang Liao, Yang Jun⁃Chi, et al. Flame⁃retardant and smoke⁃suppressed silicone foams with chitosan⁃based nanocoatings [J]. Industrial & Engineering Chemistry Research, 2016, 55(27): 7 239⁃7 248. |

| 35 | Jing Lyu, Sheng Zhizhi, Xu Yingying, et al. Nanoporous kevlar aerogel confined phase change fluids enable super‐flexible thermal diodes [J]. Advanced Functional Materials, 2022, 32(19): 2200137. |

| 36 | 肖维新, 袁静, 严开祺, et al. 生物聚合物气凝胶的制备与应用研究进展 [J]. 材料导报, 2022, 36(20): 243⁃252. |

| XIAO W X, YUAN J, YAN L Q, et al. Progress in the preparation and application of biopolymer aerogels[J]. Materials Reports, 2022, 36(20): 243⁃252. | |

| 37 | Wen He, Han Qiang, Shuang Liang, et al. Hierarchically porous wood aerogel/polypyrrole(PPy) composite thick electrode for supercapacitor [J]. Chemical Engineering Journal, 2022, 446: 137331. |

| 38 | Lei Hu, He Rujie, Lei Hongshuai, et al. Carbon aerogel for insulation applications: A review [J]. International Journal of Thermophysics, 2019, 40(4): 39. |

| 39 | Lee Jong⁃Hoon, Park Soo⁃Jin. Recent advances in preparations and applications of carbon aerogels: A review [J]. Carbon, 2020, 163: 1⁃18. |

| 40 | Zheng Haohui, Chen Gaofeng, Gan Lihui, et al. Iron⁃adjustable compressible elastic chitosan⁃derived carbon aerogel with wide⁃range linear sensitivity and super sensing performances for wearable piezoresistive sensors [J]. ACS Sustainable Chemistry & Engineering, 2022, 10(32): 10 604⁃10 614. |

| 41 | Chen Zehong, Hao Zhuo, Hu Yijie, et al. Wood‐derived lightweight and elastic carbon aerogel for pressure sensing and energy storage [J]. Advanced Functional Materials, 2020, 30(17): 1910292. |

| 42 | Maleki Hajar. Recent advances in aerogels for environmental remediation applications: a review [J]. Chemical Engineering Journal, 2016, 300: 98⁃118. |

| 43 | Liu Yanyang, Ke Yangli, Shang Qigao, et al. Fabrication of multifunctional biomass⁃based aerogel with 3D hierarchical porous structure from waste reed for the synergetic adsorption of dyes and heavy metal ions [J]. Chemical Engineering Journal, 2023, 451: 138934. |

| 44 | Fang Bixing, Dong Lina, Ding Xingwei, et al. Black fungus derived aerogel with double faced properties [J]. Chinese Chemical Letters, 2019, 30(6): 1 178⁃1 181. |

| 45 | Dan Hongbing, Ji Kaidi, Yue Gao, et al. Fabrication of superhydrophobic Enteromorpha⁃derived carbon aerogels via NH(4)H(2)PO(4) modification for multi⁃behavioral oil/water separation[J]. Science of the Total Environment, 2022, 837: 155869. |

| 46 | Dan Peng, Zhao Jie, Liang Xujun, et al. Corn stalk pith⁃based hydrophobic aerogel for efficient oil sorption [J]. J Hazard Mater, 2023, 448: 130954. |

| 47 | Chen Kouqin, Wang Liming, Xu Lihui, et al. Preparation of peanut shell cellulose nanofibrils and their superhydrophobic aerogels and their application on cotton fabrics [J]. Journal of Porous Materials, 2022, 30(2): 471⁃483. |

| 48 | Zhao Jiaojiao, Zhou Jianhua, Hong Li, et al. Directional fabricating of flexible and compressible cellulose nanofibril composite cryogel with excellent thermal insulation, flame⁃retardancy and radiative cooling for efficient thermal management [J]. Cellulose, 2022, 29(18): 9 671⁃9 691. |

| 49 | Garemark Jonas, Jesús E Perea⁃Buceta, Felhofer Martin, et al. Strong, shape⁃memory lignocellulosic aerogel via wood cell wall nanoscale reassembly [J]. ACS Nano, 2023, 17(5): 4 775⁃4 789. |

| 50 | Wang Yushu, Liu Jinru, Zhao Yuhang, et al. Temperature⁃triggered fire warning PEG@wood powder/carbon nanotube/calcium alginate composite aerogel and the application for firefighting clothing [J]. Composites Part B: Engineering, 2022, 247: 110348. |

| 51 | Han Xinhong, Ding Shaoqiu, Fan Liwu, et al. Janus biocomposite aerogels constituted of cellulose nanofibrils and MXenes for application as single⁃module solar⁃driven interfacial evaporators [J]. Journal of Materials Chemistry A, 2021, 9(34): 18 614⁃18 622. |

| 52 | Huang Jieyu, Li Dawei, Min Zhao, et al. Flexible electrically conductive biomass⁃based aerogels for piezoresistive pressure/strain sensors [J]. Chemical Engineering Journal, 2019, 373: 1 357⁃1 366. |

| 53 | Yong Huang, Peng Zhou, Zhang Xinxing. Green synthesis of ag⁃doped cellulose aerogel for highly sensitive, flame retardant strain sensors [J]. Cellulose, 2022, 29(16): 8 719⁃8 731. |

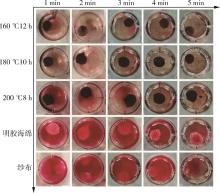

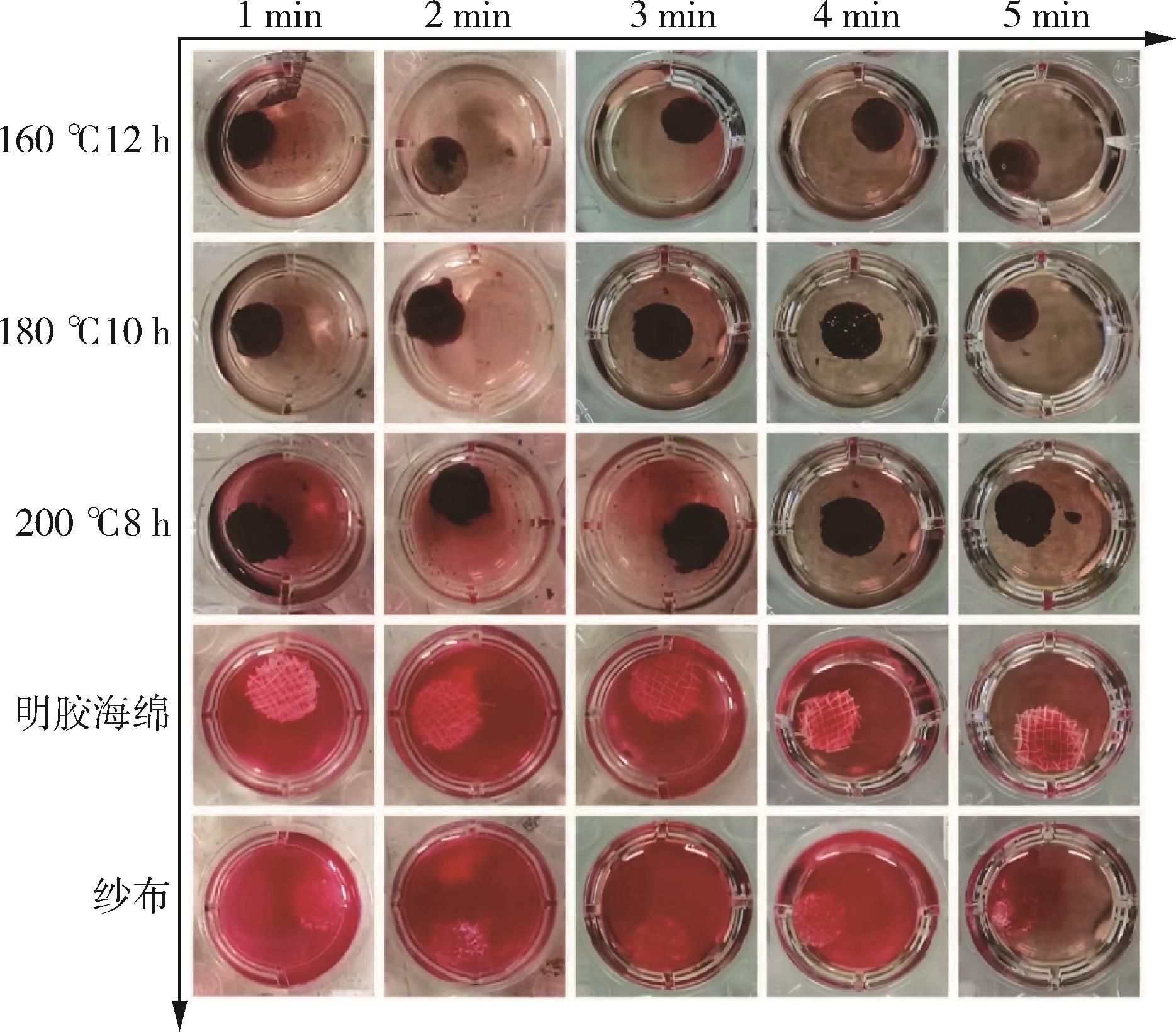

| 54 | Yang Ganghua, Huang Zhenzhen, Alec Mc Carthy, et al. Super⁃elastic carbonized mushroom aerogel for management of uncontrolled hemorrhage [J]. Advanced Science (Weinh), 2023, 10(16): e2207347. |

| [1] | 王栋. 金属有机框架基阻燃剂在阻燃领域的研究进展[J]. 中国塑料, 2024, 38(2): 118-125. |

| [2] | 潘伯超, 林晨熹, 汤栋霖. 生物基聚脲酰胺的制备及性能研究[J]. 中国塑料, 2024, 38(1): 1-6. |

| [3] | 韦代东, 李惠枝, 曾娟娟, 赵传国, 李士强. 生物基聚氨酯抗涂鸦自清洁涂料的制备及性能[J]. 中国塑料, 2023, 37(2): 15-21. |

| [4] | 马俊丞, 徐双平, 王馨甜, 贾宏葛, 张明宇, 蘧延庆. 生物基材料在碘吸附中的研究进展[J]. 中国塑料, 2023, 37(11): 178-191. |

| [5] | 杨洋, 韩宇, 翁云宣, 宋鑫宇, 黄志刚, 张彩丽. 环氧大豆油⁃癸二酸低分子量聚酯对PVC增塑性能的研究[J]. 中国塑料, 2023, 37(11): 87-94. |

| [6] | 陈淑花, 任子萌, 孙婷婷. 壳聚糖/壳聚糖接枝氧化石墨烯复合气凝胶的制备及性能研究[J]. 中国塑料, 2022, 36(9): 32-37. |

| [7] | 黄嘉伟, 韩小龙, 吴悠, 靳玉娟, 王朝. 生物基工程聚酯弹性体对聚(3⁃羟基丁酸酯⁃co⁃3⁃羟基戊酸酯)的增韧改性研究[J]. 中国塑料, 2022, 36(9): 24-31. |

| [8] | 周舒毅, 朱敏, 刘忆颖, 曹舒惠, 蔡启轩, 聂慧, 张玉霞, 周洪福. 高分子止血材料研究进展[J]. 中国塑料, 2022, 36(7): 74-84. |

| [9] | 李金凤, 梁卓恩, 彭新龙. 膨胀型阻燃剂/二乙基次磷酸铝阻燃改性不饱和树脂基复合材料[J]. 中国塑料, 2022, 36(6): 116-123. |

| [10] | 李梦琪, 陈雅君. 纳米材料阻燃聚乳酸的研究进展[J]. 中国塑料, 2022, 36(4): 102-114. |

| [11] | 韩顺涛, 段昌榆, 李明谦, 马秀清. 聚酰胺6无卤阻燃改性的研究进展[J]. 中国塑料, 2022, 36(12): 133-141. |

| [12] | 刘祥贵, 方伟, 舒洪斌, 郑根稳, 刘海. 水滑石填充PVC复合材料的制备及性能研究[J]. 中国塑料, 2021, 35(7): 63-68. |

| [13] | 何银通, 梁家琪, 刘鲁斌, 徐悦, 王可竹, 余航, 王淑慧, 许苗军. 耐水阻燃透明型环氧树脂的制备及其应用研究[J]. 中国塑料, 2021, 35(5): 6-10. |

| [14] | 王维, 王冬, 东为富. 新型疏水聚氨酯硬质泡沫的绿色制备及其性能研究[J]. 中国塑料, 2021, 35(4): 23-29. |

| [15] | 宋昆朋, 王银杰, 刘吉平, 方祝青, 杨威威, 郑东森. 磷腈化合物在阻燃聚合物领域的研究进展[J]. 中国塑料, 2021, 35(2): 107-118. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2