京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (6): 126-132.DOI: 10.19491/j.issn.1001-9278.2025.06.021

• 综述 • 上一篇

宁丁怡( ), 赵恬娇, 董亚鹏, 王美珍, 郝新宇, 王波(

), 赵恬娇, 董亚鹏, 王美珍, 郝新宇, 王波( )

)

收稿日期:2024-12-04

出版日期:2025-06-26

发布日期:2025-06-20

通讯作者:

王波(1988-),男,教授,博士,主要从事高分子材料功能化改性研究,wangbo@tyust.edu.cn作者简介:宁丁怡(2001-),女,硕士研究生,主要从事高分子材料功能化改性研究,s202421211098@stu.tyust.edu.cn

基金资助:

NING Dingyi( ), ZHAO Tianjiao, DONG Yapeng, WANG Meizhen, HAO Xinyu, WANG Bo(

), ZHAO Tianjiao, DONG Yapeng, WANG Meizhen, HAO Xinyu, WANG Bo( )

)

Received:2024-12-04

Online:2025-06-26

Published:2025-06-20

Contact:

WANG Bo

E-mail:s202421211098@stu.tyust.edu.cn;wangbo@tyust.edu.cn

摘要:

从聚乳酸(PLA)分子链结构带来的结晶与力学性能的不足出发,综述了近年来国内外在PLA共混改性改善其结晶和力学性能的研究进展,主要涉及弹性体改性、合金化改性、无机材料改性、纳米粒子改性、生物质材料改性、成核剂改性、扩链剂改性、协同改性等方面。基于此,提出了选择可生物降解填料或生物基来源的填料与PLA共混改性并妥善解决其界面问题,同时开发具有低成本、与PLA相容性良好且具有“绿色”禀赋的改性剂及其复配体系是未来通过共混改性PLA,从而获得优异性能材料的重要途径。

中图分类号:

宁丁怡, 赵恬娇, 董亚鹏, 王美珍, 郝新宇, 王波. 共混改性调控聚乳酸结晶及力学性能的研究进展[J]. 中国塑料, 2025, 39(6): 126-132.

NING Dingyi, ZHAO Tianjiao, DONG Yapeng, WANG Meizhen, HAO Xinyu, WANG Bo. Research progress in blending modification for regulating crystallization and mechanical properties of poly(lactic acid)[J]. China Plastics, 2025, 39(6): 126-132.

| 1 | 宋洁,张蓉,韩家旋,等. PLA/天然废弃植物源提取物复合材料的制备与性能[J]. 化工新型材料,2024,52(06):247⁃252,258. |

| SONG J, ZHANG R, HAN J X,et al. Preparation and properties of PLA/natural waste plant extract composites[J]. New Chemical Materials,2024,52(06): 247⁃252,258. | |

| 2 | Wei D, Wang G, Lou Z,et. al . Impact of aromatic sulfonate derivative on the crystallization,thermal resistance,and hydrolytic properties of poly(lactic acid)[J]. Polymers For Advanced Technologies,2024,35(06):1⁃11. |

| 3 | CHEN X J, DING Y L, LI Y, et al. Modification of polylactide by poly(ionic liquid)⁃b⁃polylactide copolymer and bio⁃based ionomers: Excellent toughness, transparency and antibacterial property[J]. International Journal of Biological Macromolecules,2022,221,1 512⁃1 526. |

| 4 | 吕超,罗书品,唐启恒,等. 木纤维添加量对木纤维/聚乳酸复合材料性能影响[J]. 木材科学与技术,2024,38(05): 68⁃76. |

| LYU C, LUO S P, TANG Q H. Effect of wood fiber content ratios on the properties of wood fiber/poly lactic acid composite materials[J]. Chinese Journal of Wood Science and Technology,2024,38(05): 68⁃76. | |

| 5 | FENG S Y, ZHAO W C, HE J H,et al. High Performance Polylactide Toughened by Supertough Polyester Thermoplastic Elastomers: Properties and Mechanism[J]. Chemical Research in Chinese Universities,2023,39(5): 750⁃756. |

| 6 | LONG Y R, LI H C, LI R B,et al. Modification on crystallization behavior and mechanical properties of polylactide by the addition of polyamide elastomer[J]. Colloid and Polymer Science,2023,301(8): 967⁃977. |

| 7 | 孟维晓,李国华,张计敏,等. 聚丙烯酸酯弹性体/聚乳酸共混物的结晶性能[J]. 高分子材料科学与工程,2021,37(09): 53⁃59. |

| 8 | Han K. Toughening Modification of Polylactic Acid by Thermoplastic Silicone Polyurethane Elastomer[J]. Polymers,2021,13(12): 1 953. |

| 9 | Tessanan W, Phinyocheep P. Toughening modification of poly(lactic acid) using modified natural rubber[J].Iranian Polymer Journal, 2022,31(4): 455⁃469. |

| 10 | 席立锋,周衡书,周忠成,等. 丙烯基弹性体增韧聚乳酸熔喷成型及性能[J]. 工程塑料应用,2022,50(03): 32⁃37. |

| XI L F, ZHOU H S, ZHOU Z C,et. al . Preparation and Properties of PBE/PLA Melt⁃blown Nonwovens[J]. Engineering Plastics Application,2022,50(03): 32⁃37. | |

| 11 | Long Y, Li H, Li R,et. al . Modification on crystallization behavior and mechanical properties of polylactide by the addition of polyamide elastomer[J]. Colloid and Polymer Science,2023,301: 967⁃977. |

| 12 | 喻咏,滕明才,程前,等. 聚对苯二甲酸⁃己二酸丁二醇酯/聚乳酸可降解复合材料的制备及其性能研究[J]. 化学推进剂与高分子材料,2024,22(04): 56⁃60. |

| YONG Y, TENG M C, CHENG Q,et. al . Study on preparation of poly(butylene adipate⁃co⁃terephthalate)/polylactic acid degradable composites and their performance [J]. Chemical Propellants & Polymeric Materials,2024,22(04): 56⁃60. | |

| 13 | LI C, WANG B A, SHANG Z M,et. al . High⁃barrier poly(butylene succinate⁃co⁃terephthalate) blend with poly(lactic acid) as biodegradable food packaging films[J]. Industrial & Engineering Chemistry Research,2023,62(18): 7 250⁃7 261. |

| 14 | 陈荣源,陶林娜,赵凌锋,等. 聚乳酸/聚乙烯复合材料的制备与性能[J]. 塑料,2023,52(03): 166⁃171. |

| CHEN R Y, TAO L N, ZHAO L F,et. al . Preparation and properties of polylactic acid / polyethylene composite[J]. Plastics,2023,52(03): 166⁃171. | |

| 15 | 林强,丁正,王迎雪,等. PLA/PBAT复合材料的结构与性能[J]. 塑料,2016,45(03): 65⁃67. |

| LIN Q, DING Z, WANG Y X,et. al . Structure and properties of PLA/PBAT composite[J]. Plastics,2016,45(03): 65⁃67. | |

| 16 | 杨皓然,张荣希,段同生,等. 高韧耐热PLA/PBS共混材料的制备及性能[J]. 工程塑料应用,2022,50(06): 25⁃30. |

| YANG H R, ZHANG R X, DUAN T S,et. al . Preparation and properties of PLA/PBS blends with high toughness and heat resistance[J]. Engineering Plastics Application,2022,50(06): 25⁃30. | |

| 17 | Burzic I, Pretschuh C, Kaineder D. Impact modification of PLA using biobased biodegradable PHA biopolymers[J]. European Polymer Journal,2019,114: 32⁃38. |

| 18 | Aslan M, Gananiar K, Buyukkaya U S T K. Physio⁃mechanical Characterization and Thermal Property Evaluation of Polylactic Acid/Waste Hazelnut Shell Flour Composite with Inorganic Additives[J]. Journal of Testing and Evaluation,2023,51(5): 3 390⁃3 401. |

| 19 | DING Y, ZHANG C, LUO C C,et al. Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends[J]. e⁃Polymers,2021,21(1): 234⁃243. |

| 20 | Foster C W, Down M P, Zhang Y,et. al . 3D Printed Graphene Based Energy Storage Devices[J]. Scientific Reports,2017,7: 42233. |

| 21 | Shakoor A, Thomas N.L. Talc as a nucleating agent and reinforcing filler in poly(lactic acid) composites[J]. Polymer Engineering and Science,2014,54(1):64⁃70. |

| 22 | Ji N Y, Yu X X, Shi B N,et al. Morphological structure,impact toughness,thermal property and kinetic analysis on the cold crystallization of poly (lactic acid) bio⁃composites toughened by precipitated barium sulfate[J]. Polymer Degradation and Stability,2018,158: 176⁃189. |

| 23 | 刘丽华,查玉莹,李友智,等. 贝壳粉对PLA复合材料力学性能和热稳定性的影响[J]. 塑料科技,2019,47(11):85⁃90. |

| LIU L H, CHA Y Y, LI Y Z,et. al . Effect of Shell powders on mechanical properties and thermal stability of PLA composites[J]. Plastics Science and Technology,2019,47(11):85⁃90. | |

| 24 | 刘逸涵,边俊甲,潘宏伟,等. 铝酸酯改性碳酸钙提高聚乳酸的韧性和生物降解性[J]. 塑料科技,2020,48(05):60⁃65. |

| LIU Y H, BIAN J J, PAN H W,et. al . Aluminate modified calcium carbonate to improve toughness and biodegradability of polylactic acid[J]. Plastics Science and Technology,2020,48(05):60⁃65. | |

| 25 | SU X L, ZHAI Y L, JIA C,et al. Improved Antibacterial Properties of Polylactic Acid⁃Based Nanofibers Loaded with ZnO⁃Ag Nanoparticles through Pore Engineering[J]. ACS applied materials & interfaces,2023,15(36): 42 920⁃42 929. |

| 26 | Wang B, Zhang X, Zhang L T,et al. Simultaneously reinforcing and toughening poly(lactic acid) by incorporating reactive melt⁃functionalized silica nanoparticles[J]. Journal of Applied Polymer Science,2020,137(26): 48834. |

| 27 | 余富忠. 聚乳酸/纳米钛复合材料的制备及性能研究[J]. 塑料工业,2020,48(09): 51⁃55,163. |

| YU F Z. The preparation and properties of nano⁃titanium/polylactic acid composite materials[J]. China Plastics Industry,2020,48(09): 51⁃55,163. | |

| 28 | 鄂 毅,邹姝燕,毛 晨,等. 聚乳酸/银纳米线纳米复合材料的制备与结晶行为[J]. 高分子材料科学与工程,2022,38(02): 80⁃87. |

| 29 | 曹鸿璋,韩德全,于晓丽,等. 氢氧化镧纳米晶须制备及增韧改性聚乳酸研究[J]. 稀土,2022,43(04): 46⁃54. |

| 30 | 李双雯,崔永生,张 琳,等.聚乳酸/可再生胶原⁃纤维素复合材料的制备[J]. 工程塑料应用,2023,51(09): 27⁃31,39. |

| LI S W, CUI Y S, ZHANG L,et al. Preparation and characterization of reproducible polylactic acid/collagen⁃cellulose composites[J]. Engineering Plastics Application,2023,51(09): 27⁃31,39. | |

| 31 | 王思,关斌. 新能源汽车内饰用麻纤维/聚乳酸复合材料老化性能研究[J]. 造纸科学与技术,2024,43(03): 75⁃78. |

| WANG S,GUAN B,Study on Aging Properties of Hemp Fiber/Polylactic Acid Composite for Interior Decoration of New Energy Vehicles[J]. Paper Science and Technology,2024,43(03): 75⁃78. | |

| 32 | 戚士界,游翔宇,王瑞晨,等. 高木质素含量聚乳酸共混材料的制备及其性能研究[J]. 中国塑料,2024,38(02): 45⁃51. |

| QI S J, YOU X Y, WANG R C,et. al . Preparation and properties of poly(lactic acid)/lignin blends with high lignin content[J]. China Plastics,2024,38(02): 45⁃51. | |

| 33 | Zhang L, Lv S S, Sun C,et al. Effect of MAH⁃g⁃PLA on the Properties of Wood Fiber/Polylactic Acid Composites[J]. Polymers,2017,9(11): 591. |

| 34 | Zhang K Q, Chen Z H, Smith Lee M.,et al. Polypyrrole⁃modified bamboo fiber/polylactic acid with enhanced mechanical,the antistatic properties and thermal stability[J]. Industrial Crops and Products,2021,162: 113227. |

| 35 | Olaiya ,N.G., Maraveas ,C., Salem ,M.A.,et. al . Viscoelastic and Properties of Amphiphilic Chitin in Plasticised Polylactic Acid/Starch Biocomposite[J]. Polymers,2022,14(11): 2268. |

| 36 | Zhao X, Yu J, Liang X,et. al . Crystallization behaviors regulations and mechanical performances enhancement approaches of polylactic acid (PLA) biodegradable materials modified by organic nucleating agents[J]. International Journal of Biological Macromolecules,2023,233: 123581⁃123597. |

| 37 | LI C H, JIANG T, WANG J F,et.al. Enhancing the Oxygen⁃Barrier Properties of Polylactide by Tailoring the Arrangement of Crystalline Lamellae[J]. ACS Sustainable Chemistry & Engineering,2018,6(5): 6247⁃6255. |

| 38 | Han D, Tian H, Liu L,et al. Scalable manufacturing of an amide⁃based nucleating agent for transparency and high heat resistance of polylactic acid[J]. International Journal of Biological Macromolecules,2024,264: 130574. |

| 39 | Liu S, He Y, Qu J P. Manufacturing High⁃Performance Polylactide by Constructing 3D Network Crystalline Structure with Adding Self⁃Assembly Nucleator[J]. Industrial ang Engineering Chemistry Research,2022,61(37): 4567⁃4578. |

| 40 | 张靖倩,曾广胜,彭军,等. 酰肼成核剂对聚乳酸结晶和力学性能的影响[J]. 材料科学与工程学报,2024,42(03): 427⁃434. |

| ZHANG Q Q, ZENG G S, PENG J,et. al . Effects of Hydrazide Nucleating Agents on Crystallization and Mechanical Properties of Polylactic Acid[J]. Journal of Materials Science ang Engineering,2024,42(03): 427⁃434. | |

| 41 | 郭盛. 聚乳酸纤维的晶体结构与性能研究[D]. 上海: 东华大学,2023. |

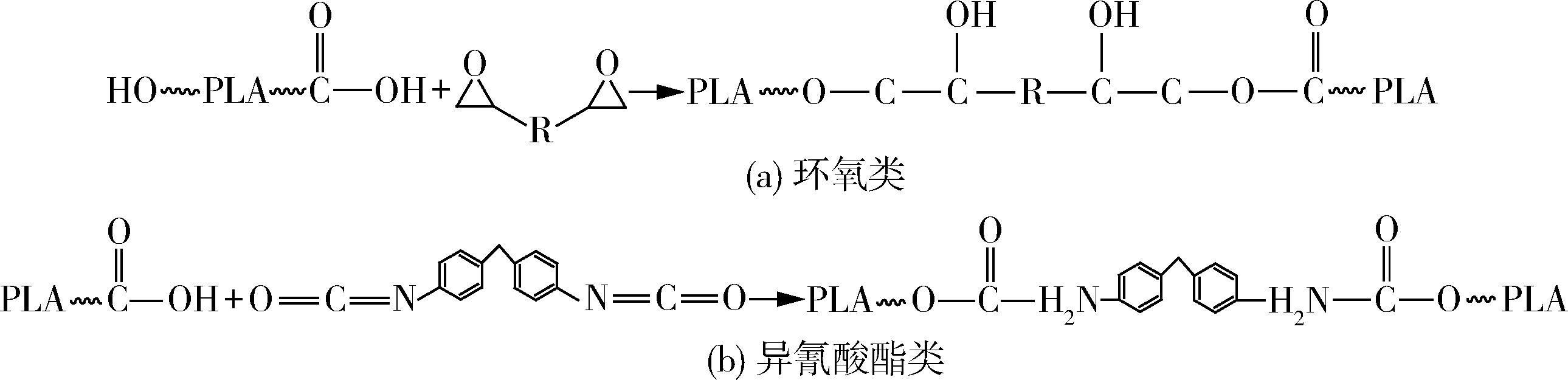

| 42 | 陈志琪,潘均安,阳范文,等.环氧扩链剂对聚乳酸性能的影响[J]. 工程塑料应用,2022,50(06): 144⁃148. |

| CHEN Z Q, PAN J A, YANG F W,et. al . Effect of Epoxy Chain Extender on Properties of Polylactic Acid[J]. Engineering Plastics Application,2022,50(06): 144⁃148. | |

| 43 | Karkhanis Sonal S., Matuana Laurent M.. Extrusion blown films of poly(lactic acid) chain⁃extended with food grade multifunctional epoxies[J]. Polymer Engineering and Science,2019,59: 2211⁃2219. |

| 44 | Luo W, Yang Y, Weng Y X,et al. Epoxidized cardanol oleate (ECD⁃OA) as an effective biobased chain extender of polylactic acid (PLA)[J]. International Journal of Biological Macromolecules,2024,282: 136903. |

| 45 | Barczewski M, Aniko J, Hejna A,et al. The use of chain extenders as processing aids in the valorization of single⁃use polylactide (PLA) products by rotomolding[J]. Journal of Cleaner Production,2024,478: 143969. |

| 46 | Aleksanyan V K, Smykovskaya S R, Samoilova A N,et al. Development of Poly(lactic acid)⁃Based Biocomposites with Silver Nanoparticles and Investigation of Their Characteristics[J]. Polymers,2024,16(19): 2758⁃2758. |

| 47 | 张克宏,王逍冉. 纳米纤维素协同聚氨酯增强增韧聚乳酸的研究[J]. 中国塑料,2020,34(11): 23⁃28. |

| ZHANG K H, WANG X R. Investigation on Reinforced and Toughened PLA with NCF and PU[J]. China Plastics,2020,34(11): 23⁃28. | |

| 48 | Barczewski Mateusz, Mysiukiewicz Olga, Matykiewicz Danuta,et al. Development of polylactide composites with improved thermomechanical properties by simultaneous use of basalt powder and a nucleating agent[J]. Polymer Composites,2020,41: 2947⁃2957. |

| 49 | 王杰,辛德华,李晖,等. 纳米黏土与二氧化硅协同改性聚乳酸研究[J]. 中国塑料,2024,38(07): 43⁃48. |

| WANG J, XIN D H, LI H,et. al . Effect of hybrid reinforcement of nanoclay and silica on properties of poly(lactic acid)[J]. China Plastics,2024,38(07): 43⁃48. | |

| 50 | 丁馨怡,顿东星,秦骏熙,等. 成核剂ST⁃NAB3改性扩链聚乳酸的微观结构与性能研究[J]. 中国塑料,2024,38(09): 41⁃46. |

| DING X Y, DUNG D X, QIN J X,et. al . Study on microstructure and properties of ST/NAB3 nucleating agent modified chain extended polylactic acid[J]. China Plastics,2024,38(09): 41⁃46. | |

| 51 | 王澳华,顿东星,孟瑞静,等. 癸二酸二苯基二酰肼调控扩链改性聚乳酸的性能[J]. 中国塑料,2024,38(11): 64⁃69. |

| WANG A H, DUN D X, MENG R J,et. al . Study on performance regulation of chain extended poly(lactic acid) foams with diphenylhydrazide sebacic acid[J]. China Plastics,2024,38(11): 64⁃69. |

| [1] | 吴希然, 贾志欣, 刘立君, 李继强, 赵川涛, 陈博杰. PP⁃CGFR/PP⁃LGFR热压⁃注塑一体成型制品力学性能分析[J]. 中国塑料, 2025, 39(5): 1-8. |

| [2] | 李文卓, 邱穆楠, 温变英. 高分子材料在新能源汽车功能部件中的应用研究进展[J]. 中国塑料, 2025, 39(5): 132-138. |

| [3] | 冯硕, 周舒毅, 焦洋, 胡淼, 张若轩, 靳玉娟. 端环氧型超支化聚酯对聚乳酸/滑石粉复合材料性能的影响研究[J]. 中国塑料, 2025, 39(5): 36-42. |

| [4] | 陈梦, 李文良, 张涛, 张文才, 杨喜英. 胶粉/SBS复合改性沥青抗老化性能与机理研究[J]. 中国塑料, 2025, 39(5): 43-49. |

| [5] | 郭伟超, 辛晓行, 曾山林, 高新勤, 汤奥斐. 区域分割打印对FDM 3D打印件性能的影响[J]. 中国塑料, 2025, 39(5): 57-62. |

| [6] | 陈业中, 龚德君, 付学俊, 欧阳春平, 张怡, 尹衍升. 润滑剂种类对PBAT/PLA/碳酸钙复合材料力学性能与散发性能的影响[J]. 中国塑料, 2025, 39(5): 77-82. |

| [7] | 栗小茜, 陈浩, 葛正浩, 宋浩杰, 高彦军. 车用碳纤维复合材料结构优化与性能研究进展[J]. 中国塑料, 2025, 39(4): 118-125. |

| [8] | 张衡, 刘浩, 邱守季, 张炳, 吴叔青. 具有优异力学性能的钛白粉增白GFRPA复合材料的制备及性能研究[J]. 中国塑料, 2025, 39(3): 12-18. |

| [9] | 杨青林, 周松, 李璨然, 余闻达, 罗玉梅. SEBS⁃g⁃MAH对PPO/PA66复合材料性能和形貌的影响[J]. 中国塑料, 2025, 39(3): 30-35. |

| [10] | 张勋, 刘翔, 方梅, 郭攀, 冯跃战, 黄明, 刘春太. 基于动态高分子基复合材料的一体化T型加筋壁板力学性能仿真研究[J]. 中国塑料, 2025, 39(3): 53-59. |

| [11] | 张伟臻, 张琦, 李源, 卢咏来, 张师军. 环氧化硅橡胶/甲基硅橡胶增韧PA6/CF复合材料的制备与性能研究[J]. 中国塑料, 2025, 39(3): 7-11. |

| [12] | 武本泽, 李滨, 雷园, 黄绍军, 吕汶骏, 余传柏. 表面改性Sb2O3对阻燃ABS/DBDPE/ Sb2O3复合材料性能的影响[J]. 中国塑料, 2025, 39(3): 81-85. |

| [13] | 李万隆, 杨卫民, 王朔, 李长金, 张杨, 谭晶, 阎华, 李好义. CH⁃S04对熔体微分电纺聚乳酸纤维的增强改性研究[J]. 中国塑料, 2025, 39(2): 1-5. |

| [14] | 余田亮, 陈文革, 陈施润, 陈达, 周伟, 周兰燕. 石墨烯增强PE复合材料的组织与性能研究[J]. 中国塑料, 2025, 39(2): 15-20. |

| [15] | 张辉, 唐站站, 鲍海霞, 程鑫远, 陈斌. 不同环境温度下UPVC管材的力学性能退化研究[J]. 中国塑料, 2025, 39(2): 26-31. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2